Nylon film offers a smooth, durable surface ideal for packaging and protective coatings, while nylon fiber provides exceptional strength and flexibility for textiles and industrial applications. The film form excels in moisture resistance and barrier properties, whereas nylon fiber is prized for its elasticity and abrasion resistance. Choosing between nylon film and fiber depends on the specific performance requirements and end-use needs of the product.

Table of Comparison

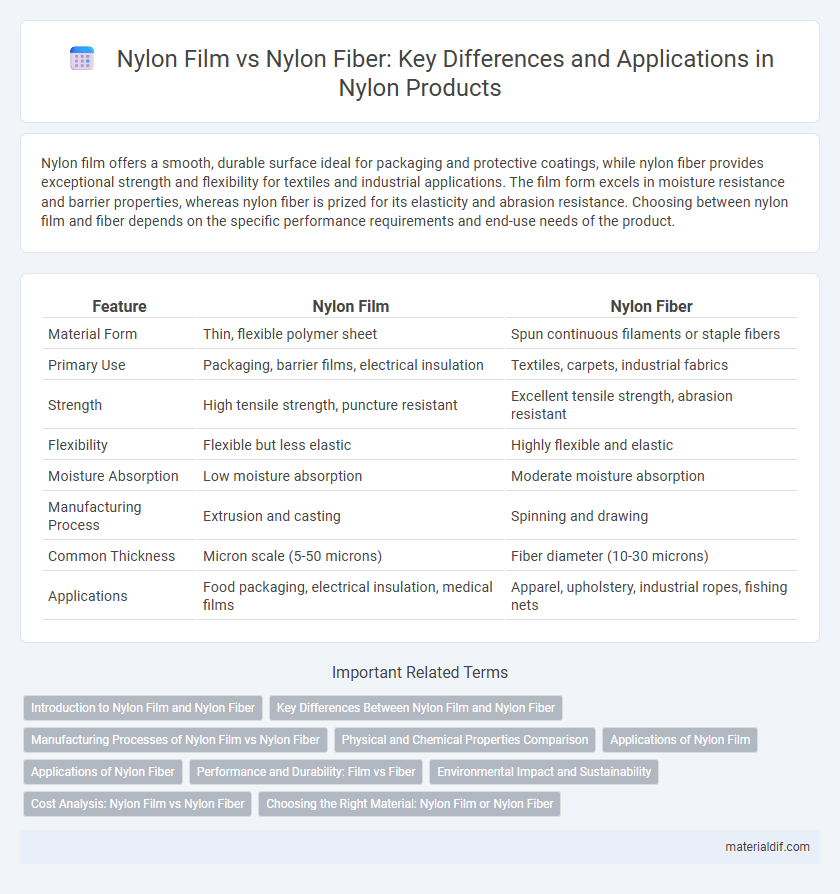

| Feature | Nylon Film | Nylon Fiber |

|---|---|---|

| Material Form | Thin, flexible polymer sheet | Spun continuous filaments or staple fibers |

| Primary Use | Packaging, barrier films, electrical insulation | Textiles, carpets, industrial fabrics |

| Strength | High tensile strength, puncture resistant | Excellent tensile strength, abrasion resistant |

| Flexibility | Flexible but less elastic | Highly flexible and elastic |

| Moisture Absorption | Low moisture absorption | Moderate moisture absorption |

| Manufacturing Process | Extrusion and casting | Spinning and drawing |

| Common Thickness | Micron scale (5-50 microns) | Fiber diameter (10-30 microns) |

| Applications | Food packaging, electrical insulation, medical films | Apparel, upholstery, industrial ropes, fishing nets |

Introduction to Nylon Film and Nylon Fiber

Nylon film is a thin, transparent synthetic polymer sheet used primarily for packaging and industrial applications due to its excellent barrier properties and durability. Nylon fiber, derived from polyamide polymers, is a strong, lightweight textile material commonly employed in clothing, carpets, and ropes for its elasticity and abrasion resistance. Both forms originate from similar chemical structures but serve distinct purposes based on their physical characteristics and manufacturing processes.

Key Differences Between Nylon Film and Nylon Fiber

Nylon film is a thin, flexible sheet primarily used for packaging, insulation, and barrier applications due to its excellent tensile strength and moisture resistance. Nylon fiber, on the other hand, is a spun material commonly utilized in textiles, ropes, and industrial fabrics because of its durability, elasticity, and abrasion resistance. The key differences lie in their physical form, application areas, and mechanical properties, with nylon film offering a smooth, impermeable surface and nylon fiber providing strength and flexibility in woven or knitted forms.

Manufacturing Processes of Nylon Film vs Nylon Fiber

Nylon film is produced through a casting or extrusion process where molten nylon is spread into thin sheets and rapidly cooled to form uniform, transparent films with controlled thickness. Nylon fiber manufacturing involves melt spinning or solution spinning techniques, where nylon polymer is extruded through spinnerets, then drawn and oriented to enhance tensile strength and flexibility. The distinct processing methods result in different molecular alignments, affecting the mechanical properties and end-use applications of nylon film versus nylon fiber.

Physical and Chemical Properties Comparison

Nylon film exhibits superior tensile strength and chemical resistance compared to nylon fiber, making it ideal for packaging applications requiring durability and barrier properties. While nylon fiber offers flexibility and elasticity useful in textile manufacturing, nylon film provides enhanced moisture barrier and thermal stability due to its dense molecular structure. The chemical properties of nylon film, including higher resistance to oils, solvents, and abrasion, contrast with the porous and absorbent nature of nylon fibers.

Applications of Nylon Film

Nylon film is widely used in packaging applications due to its excellent barrier properties against oxygen, moisture, and chemicals, ensuring product freshness and protection. It is also employed in electrical insulation and flexible printed circuits because of its high dielectric strength and thermal resistance. Compared to nylon fiber, which is primarily utilized in textiles and apparel, nylon film's thin, strong, and transparent characteristics make it ideal for industrial and commercial packaging solutions.

Applications of Nylon Fiber

Nylon fiber is widely utilized in textile applications such as apparel, upholstery, and industrial products due to its high tensile strength, elasticity, and abrasion resistance. It is commonly used in manufacturing activewear, carpets, ropes, and tire cords, where durability and flexibility are essential. Unlike nylon film, which is favored for packaging and barrier applications, nylon fiber's versatility enables its extensive use in garments and technical textiles.

Performance and Durability: Film vs Fiber

Nylon film offers superior performance in applications requiring high tensile strength, excellent chemical resistance, and moisture barrier properties, making it ideal for packaging and electrical insulation. Nylon fiber excels in durability, providing exceptional abrasion resistance, flexibility, and resilience for textiles and industrial uses such as ropes, nets, and automotive components. The key distinction lies in nylon film's enhanced impermeability and smooth surface, while nylon fiber delivers strength and longevity through its woven structure.

Environmental Impact and Sustainability

Nylon film generally has a lower environmental footprint than nylon fiber due to its thinner material usage and reduced energy consumption during production. Nylon fiber, often used in textiles, requires extensive processing and dyeing, leading to higher water usage and chemical pollution. Recycling nylon film proves more efficient, contributing to better sustainability outcomes compared to the more complex recycling processes for nylon fibers.

Cost Analysis: Nylon Film vs Nylon Fiber

Nylon film typically incurs higher production costs due to the complex extrusion and biaxial orientation processes compared to nylon fiber, which is produced through straightforward spinning techniques. Despite its higher initial expense, nylon film offers superior barrier properties and flexibility, often justifying the increased investment for packaging and industrial applications. Cost efficiency in nylon fiber arises from its widespread manufacturing infrastructure and lower raw material consumption, making it ideal for textiles and reinforcement uses.

Choosing the Right Material: Nylon Film or Nylon Fiber

Nylon film offers exceptional barrier properties, flexibility, and transparency, making it ideal for packaging and protective coatings, while nylon fiber provides superior strength, elasticity, and abrasion resistance for textiles and industrial applications. Selecting the right material depends on the intended use: choose nylon film for moisture resistance and clarity, and nylon fiber for durability and tensile strength. Understanding the specific performance requirements ensures optimal functionality in products ranging from food packaging to high-performance fabrics.

Nylon Film vs Nylon Fiber Infographic

materialdif.com

materialdif.com