Nickel matte primarily consists of nickel, copper, and iron sulfides, making it an intermediate product in the smelting process with a high metal content. In contrast, nickel sulfide is a specific mineral compound rich in nickel and sulfur, often targeted for direct extraction in mining operations. Understanding the distinction between nickel matte and nickel sulfide is crucial for optimizing refining techniques and improving metal recovery rates in nickel production.

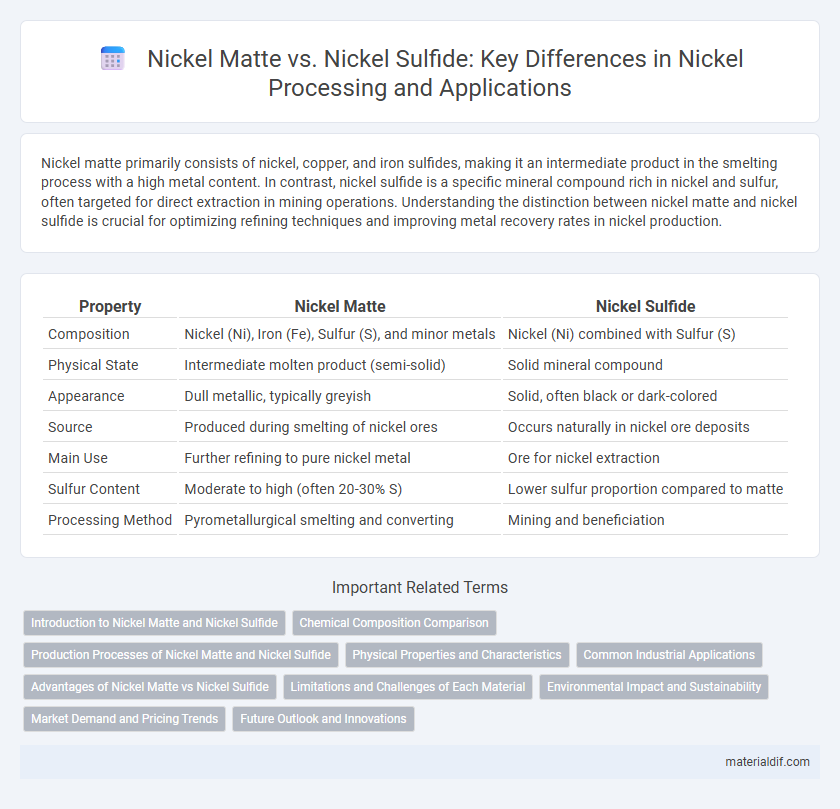

Table of Comparison

| Property | Nickel Matte | Nickel Sulfide |

|---|---|---|

| Composition | Nickel (Ni), Iron (Fe), Sulfur (S), and minor metals | Nickel (Ni) combined with Sulfur (S) |

| Physical State | Intermediate molten product (semi-solid) | Solid mineral compound |

| Appearance | Dull metallic, typically greyish | Solid, often black or dark-colored |

| Source | Produced during smelting of nickel ores | Occurs naturally in nickel ore deposits |

| Main Use | Further refining to pure nickel metal | Ore for nickel extraction |

| Sulfur Content | Moderate to high (often 20-30% S) | Lower sulfur proportion compared to matte |

| Processing Method | Pyrometallurgical smelting and converting | Mining and beneficiation |

Introduction to Nickel Matte and Nickel Sulfide

Nickel matte is a partially refined nickel product primarily composed of nickel, copper, and iron sulfides, commonly produced through the smelting process of nickel sulfide ores. Nickel sulfide refers to naturally occurring minerals containing nickel combined with sulfur, serving as the primary feedstock for extracting nickel metal. Understanding the characteristics and compositions of nickel matte and nickel sulfide is essential for optimizing nickel refining and processing operations.

Chemical Composition Comparison

Nickel matte primarily consists of nickel sulfide (NiS) combined with varying amounts of iron sulfide (FeS) and other metal sulfides, making it an intermediate product in the smelting process. In contrast, nickel sulfide refers specifically to compounds like pentlandite ((Ni,Fe)9S8) and millerite (NiS), which exhibit distinct stoichiometric ratios of nickel to sulfur. The chemical composition of nickel matte is less uniform and richer in impurities, while pure nickel sulfide minerals contain more defined nickel-to-sulfur ratios critical for refining and metallurgical applications.

Production Processes of Nickel Matte and Nickel Sulfide

Nickel matte is produced through the smelting of nickel-containing ores in a blast furnace or electric furnace, where high temperatures separate the nickel from other metals, resulting in a semi-refined alloy with significant nickel content. Nickel sulfide forms naturally in magmatic sulfide deposits and is extracted by flotation beneficiation of ore followed by smelting and converting stages to produce a high-purity nickel concentrate. The distinct production processes impact the refinement steps and final purity, with matte serving as an intermediate product requiring further refining, while sulfide ores allow direct access to nickel through well-established flotation and smelting techniques.

Physical Properties and Characteristics

Nickel matte is a intermediate product consisting primarily of nickel, iron, and sulfur with a physical appearance as a brittle, metallic solid typically gray to black in color, whereas nickel sulfide is a specific compound often found in metallurgical slag or ore with distinct crystalline structures and varying sulfur content. Nickel matte exhibits a relatively high melting point around 1250degC and moderate density near 5.7 g/cm3, while nickel sulfide compounds such as Ni3S2 possess slightly lower melting points and densities, influencing their handling and processing methods. The physical hardness and brittleness of nickel sulfide differ significantly from the more ductile nature of nickel matte, impacting their industrial applications in refining and alloy manufacturing.

Common Industrial Applications

Nickel matte primarily serves as an intermediate product in nickel refining, widely used in the production of stainless steel, alloy steels, and electroplating due to its high nickel content and ease of further processing. Nickel sulfide concentrates are favored in the extraction of high-purity nickel and cobalt, essential for battery manufacturing, particularly in electric vehicle batteries and rechargeable electronics. Both forms play crucial roles in metallurgical processes but differ in their end-use specialties within industrial applications.

Advantages of Nickel Matte vs Nickel Sulfide

Nickel matte offers higher purity levels, typically containing 70-75% nickel compared to nickel sulfide, which enhances its suitability for downstream refining and specialized alloy production. It has lower sulfur content, reducing environmental and processing challenges associated with sulfur emissions and waste management in nickel sulfide processing. The pyrometallurgical production of nickel matte allows for more energy-efficient extraction methods and improved recovery rates from laterite ores compared to traditional sulfide ore smelting.

Limitations and Challenges of Each Material

Nickel matte, primarily composed of nickel sulfide and other impurities, faces challenges in achieving consistent purity levels needed for high-grade nickel production, often requiring extensive refining processes. Nickel sulfide deposits present limitations in extraction due to their complex mineralogy and the energy-intensive nature of smelting, which also leads to environmental concerns from sulfur dioxide emissions. Both materials encounter difficulties in efficient processing and environmental compliance, impacting their overall economic viability in the nickel industry.

Environmental Impact and Sustainability

Nickel mattes, primarily composed of nickel sulfide, are intermediate products in nickel refining with varying environmental footprints due to their processing methods. Nickel sulfide ores typically require energy-intensive smelting, generating sulfur dioxide emissions that contribute to acid rain and air pollution. Sustainable practices focus on reducing emissions through advanced gas capture technologies and increasing recycling of nickel mattes to minimize mining impacts and resource depletion.

Market Demand and Pricing Trends

Nickel matte, primarily used in stainless steel production, experiences higher market demand due to its lower production cost and steady supply, resulting in generally more stable pricing trends. Nickel sulfide, favored for battery-grade nickel essential in electric vehicle manufacturing, sees fluctuating demand influenced by the growing EV market and stricter environmental regulations, leading to more volatile and often premium pricing. Shifts toward green technologies continue to increase nickel sulfide's market value, while nickel matte remains a cost-effective option for traditional industrial applications.

Future Outlook and Innovations

Technological advancements in refining processes are accelerating the transition from nickel matte to higher-purity nickel sulfide products, driven by growing demand in electric vehicle batteries and stainless steel production. Innovations in hydrometallurgical techniques enhance the efficiency of nickel sulfide extraction and reduce environmental impact, positioning nickel sulfide as a key material for future sustainable applications. Market projections indicate increasing investment in nickel sulfide projects, supported by stricter environmental regulations and the push for greener battery technologies.

Nickel matte vs Nickel sulfide Infographic

materialdif.com

materialdif.com