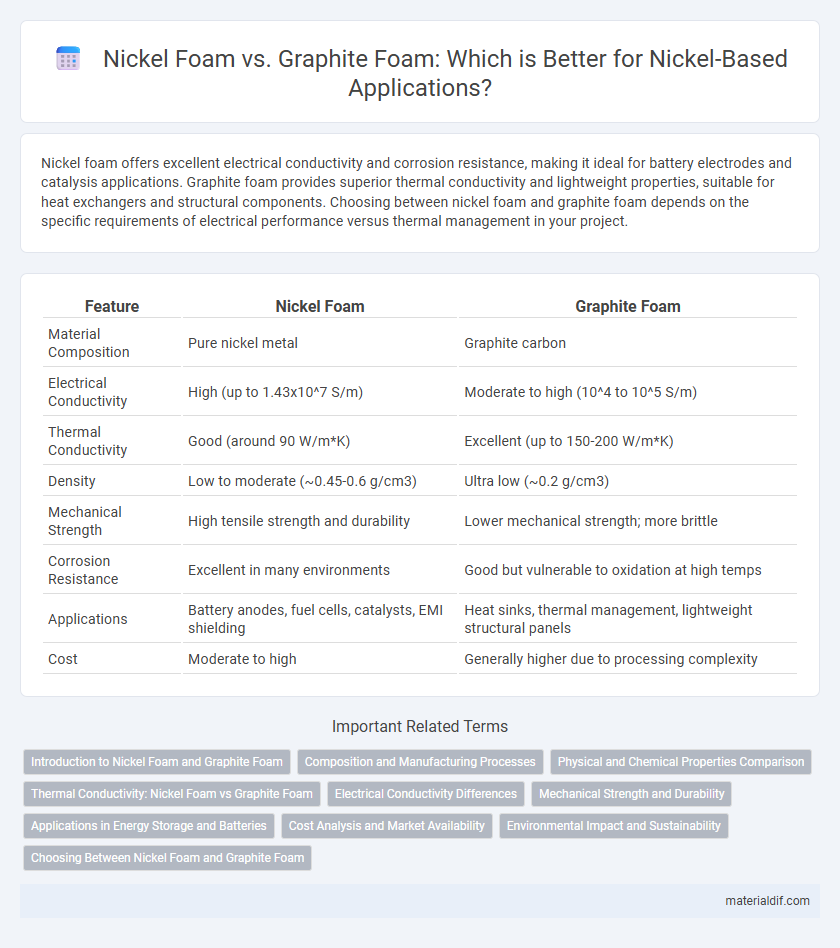

Nickel foam offers excellent electrical conductivity and corrosion resistance, making it ideal for battery electrodes and catalysis applications. Graphite foam provides superior thermal conductivity and lightweight properties, suitable for heat exchangers and structural components. Choosing between nickel foam and graphite foam depends on the specific requirements of electrical performance versus thermal management in your project.

Table of Comparison

| Feature | Nickel Foam | Graphite Foam |

|---|---|---|

| Material Composition | Pure nickel metal | Graphite carbon |

| Electrical Conductivity | High (up to 1.43x10^7 S/m) | Moderate to high (10^4 to 10^5 S/m) |

| Thermal Conductivity | Good (around 90 W/m*K) | Excellent (up to 150-200 W/m*K) |

| Density | Low to moderate (~0.45-0.6 g/cm3) | Ultra low (~0.2 g/cm3) |

| Mechanical Strength | High tensile strength and durability | Lower mechanical strength; more brittle |

| Corrosion Resistance | Excellent in many environments | Good but vulnerable to oxidation at high temps |

| Applications | Battery anodes, fuel cells, catalysts, EMI shielding | Heat sinks, thermal management, lightweight structural panels |

| Cost | Moderate to high | Generally higher due to processing complexity |

Introduction to Nickel Foam and Graphite Foam

Nickel foam is a porous metallic material characterized by high electrical conductivity, corrosion resistance, and mechanical strength, making it ideal for electrodes and battery applications. Graphite foam, composed of interconnected graphite networks, offers exceptional thermal conductivity and lightweight structural properties suited for heat exchangers and energy storage. Both materials serve distinct functions in energy and thermal management systems due to their unique physical and chemical properties.

Composition and Manufacturing Processes

Nickel foam consists of a porous structure made from pure nickel or nickel alloys, typically produced through electroplating or sintering processes that create interconnected pores for high surface area and conductivity. In contrast, graphite foam is derived from graphitized carbon, manufactured by impregnating a polyurethane foam template with a resin, followed by high-temperature pyrolysis and graphitization to develop its ordered carbon lattice. These differences in composition and manufacturing result in nickel foam exhibiting superior electrical conductivity and corrosion resistance, while graphite foam offers lower density and enhanced thermal conductivity for specific applications.

Physical and Chemical Properties Comparison

Nickel foam exhibits superior electrical conductivity and mechanical strength compared to graphite foam, making it ideal for high-performance battery electrodes and catalytic applications. Chemically, nickel foam offers excellent corrosion resistance and catalytic activity due to its metallic nature, while graphite foam is more chemically inert with higher thermal stability but lower conductivity. The porous structure of nickel foam provides enhanced surface area for electrochemical reactions, whereas graphite foam's lightweight and thermal conductivity favor heat dissipation in energy storage devices.

Thermal Conductivity: Nickel Foam vs Graphite Foam

Nickel foam typically exhibits lower thermal conductivity, ranging from 2 to 20 W/m*K, due to its metallic porous structure, while graphite foam can achieve thermal conductivities above 1000 W/m*K, leveraging its crystalline carbon lattice. The high thermal conductivity of graphite foam makes it ideal for advanced heat dissipation in electronics and aerospace applications. Nickel foam's moderate thermal conductivity combined with electrical conductivity and corrosion resistance suits battery electrodes and catalysis roles where heat management is less critical.

Electrical Conductivity Differences

Nickel foam exhibits higher electrical conductivity compared to graphite foam, with typical values ranging from 1.4 x 10^7 S/m for nickel, while graphite foam conductivity varies around 10^4 to 10^5 S/m depending on porosity and structure. The metallic nature of nickel contributes to its superior electron mobility and lower resistance, making it ideal for applications requiring efficient current conduction. Graphite foam, despite lower conductivity, offers advantages in lightweight and chemical stability, but its electrical performance is limited by carbon's semi-metallic characteristics.

Mechanical Strength and Durability

Nickel foam exhibits superior mechanical strength compared to graphite foam, offering enhanced structural integrity under high stress conditions. The durability of nickel foam surpasses that of graphite foam due to its resistance to corrosion and mechanical wear, ensuring longer operational lifespan in demanding environments. Its metal-based composition allows nickel foam to maintain performance stability, whereas graphite foam may degrade or fracture over time.

Applications in Energy Storage and Batteries

Nickel foam offers excellent electrical conductivity and corrosion resistance, making it a preferred current collector and catalyst substrate in lithium-ion and nickel-metal hydride batteries. Graphite foam provides superior thermal conductivity and structural stability, enhancing heat dissipation and mechanical integrity in advanced energy storage systems like supercapacitors and solid-state batteries. Combining these foams can optimize performance by leveraging nickel foam's electrochemical activity with graphite foam's efficient thermal management.

Cost Analysis and Market Availability

Nickel foam typically exhibits higher cost efficiency compared to graphite foam due to its lower raw material and manufacturing expenses, making it more accessible for large-scale industrial applications. Graphite foam, although offering superior thermal conductivity and lightweight properties, comes at a premium price that limits its widespread market availability primarily to niche sectors like aerospace and high-performance electronics. Market trends indicate that nickel foam maintains broader distribution channels and more stable supply chains, reinforcing its dominance in cost-sensitive markets.

Environmental Impact and Sustainability

Nickel foam exhibits higher recyclability compared to graphite foam, contributing to a reduced environmental footprint through enhanced material recovery and reuse. Graphite foam production involves high energy consumption and potential release of hazardous gases, whereas nickel foam manufacturing can leverage more sustainable electroplating processes with lower emissions. The sustainability of nickel foam is further supported by its durability and resistance to corrosion, extending product lifespan and minimizing resource depletion.

Choosing Between Nickel Foam and Graphite Foam

Nickel foam offers superior electrical conductivity and corrosion resistance, making it ideal for battery electrodes and fuel cell applications where durability and efficient electron flow are critical. Graphite foam provides excellent thermal conductivity and lightweight properties, beneficial in heat exchangers and aerospace components requiring efficient heat dissipation. Choosing between nickel foam and graphite foam depends on prioritizing electrical conductivity and chemical stability versus thermal management and weight reduction in specific industrial applications.

Nickel Foam vs Graphite Foam Infographic

materialdif.com

materialdif.com