Pure nickel offers exceptional corrosion resistance and magnetic properties, making it ideal for applications requiring high purity and consistent performance in harsh environments. Nickel alloys, on the other hand, combine nickel with other metals to enhance strength, durability, and resistance to extreme temperatures, broadening their use in aerospace, chemical processing, and marine industries. Choosing between pure nickel and nickel alloys depends on the specific requirements for mechanical properties, environmental exposure, and cost efficiency.

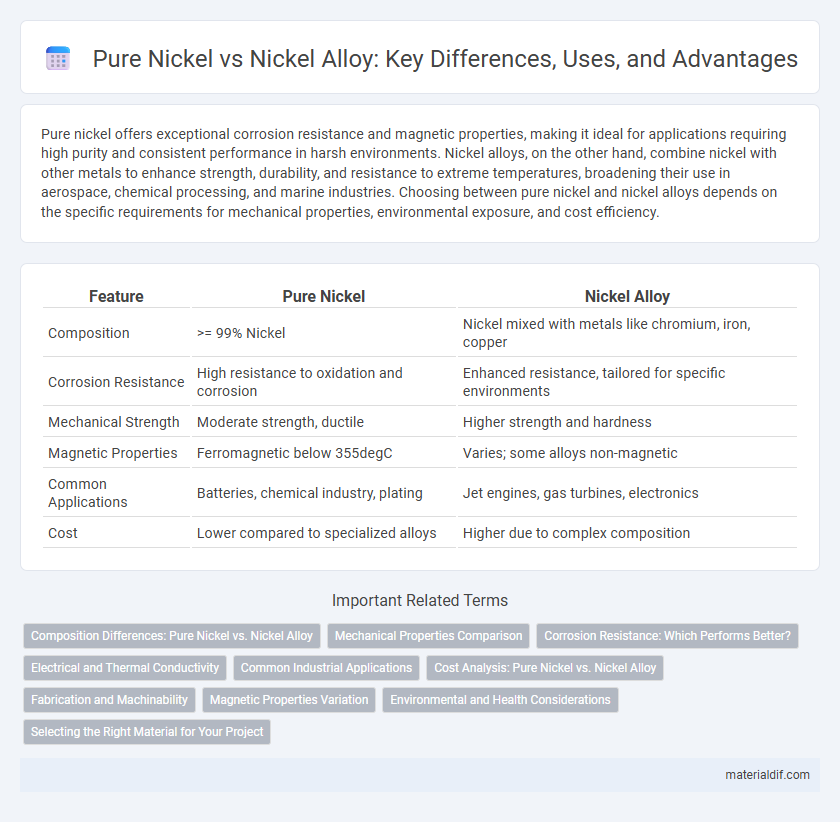

Table of Comparison

| Feature | Pure Nickel | Nickel Alloy |

|---|---|---|

| Composition | >= 99% Nickel | Nickel mixed with metals like chromium, iron, copper |

| Corrosion Resistance | High resistance to oxidation and corrosion | Enhanced resistance, tailored for specific environments |

| Mechanical Strength | Moderate strength, ductile | Higher strength and hardness |

| Magnetic Properties | Ferromagnetic below 355degC | Varies; some alloys non-magnetic |

| Common Applications | Batteries, chemical industry, plating | Jet engines, gas turbines, electronics |

| Cost | Lower compared to specialized alloys | Higher due to complex composition |

Composition Differences: Pure Nickel vs. Nickel Alloy

Pure nickel consists primarily of nickel atoms with a purity typically above 99.0%, resulting in a uniform metallic structure known for its excellent corrosion resistance and magnetic properties. In contrast, nickel alloys combine nickel with elements such as chromium, iron, molybdenum, or copper to enhance mechanical strength, heat resistance, or chemical stability, tailoring the material for specific industrial applications. The compositional variations in nickel alloys directly influence their physical and chemical characteristics, making them distinct from pure nickel in performance and usage.

Mechanical Properties Comparison

Pure nickel exhibits excellent ductility and moderate tensile strength, making it ideal for applications requiring corrosion resistance and formability. Nickel alloys, enhanced by elements such as chromium, iron, and molybdenum, offer superior mechanical strength, hardness, and fatigue resistance, enabling their use in high-stress environments like aerospace and power generation. The increased tensile strength and improved creep resistance of nickel alloys outperform pure nickel, providing greater durability under mechanical loads.

Corrosion Resistance: Which Performs Better?

Pure nickel exhibits exceptional corrosion resistance, especially in acidic and alkaline environments, making it highly suitable for chemical processing applications. Nickel alloys, such as Inconel and Monel, enhance corrosion resistance further by combining nickel with elements like chromium, iron, or copper, improving performance in highly corrosive or extreme temperature conditions. While pure nickel offers excellent baseline protection, nickel alloys typically outperform it in aggressive environments due to their tailored composition and increased durability.

Electrical and Thermal Conductivity

Pure nickel exhibits superior electrical and thermal conductivity compared to nickel alloys due to its unalloyed metallic structure, which facilitates efficient electron and heat transfer. Nickel alloys, containing elements such as chromium, iron, or copper, have reduced conductivity properties, optimized instead for enhanced mechanical strength and corrosion resistance in various industrial applications. The electrical conductivity of pure nickel typically ranges around 14 x 10^6 S/m, while nickel alloys often show significantly lower values depending on their specific composition.

Common Industrial Applications

Pure nickel exhibits excellent corrosion resistance and high thermal conductivity, making it ideal for chemical processing equipment and battery components. Nickel alloys, such as Inconel and Monel, offer enhanced strength and oxidation resistance, widely used in aerospace turbine blades, marine hardware, and nuclear reactors. The specific alloy composition tailors performance characteristics to meet demanding industrial applications requiring durability under extreme conditions.

Cost Analysis: Pure Nickel vs. Nickel Alloy

Pure nickel typically incurs higher costs due to its extensive refining process and limited availability, while nickel alloys offer cost advantages by combining nickel with other metals to enhance properties and reduce material expenses. The cost-effectiveness of nickel alloys arises from improved mechanical strength and corrosion resistance, which can lower maintenance and replacement costs in industrial applications. Evaluating total lifecycle costs, nickel alloys often present better economic value despite higher initial alloying expenses compared to pure nickel.

Fabrication and Machinability

Pure nickel offers excellent corrosion resistance and thermal conductivity, making it ideal for fabrication processes requiring high purity and uniformity. Nickel alloys, such as Inconel or Monel, provide enhanced strength and resistance to extreme environments but present greater challenges in machinability due to their hardness and work-hardening properties. Fabrication techniques for nickel alloys often require specialized tooling and slower machining speeds to maintain precision and surface finish.

Magnetic Properties Variation

Pure nickel exhibits strong ferromagnetic properties with a Curie temperature of approximately 627 K, making it highly magnetic at room temperature. Nickel alloys, such as nichrome or Monel, display varied magnetic behaviors depending on their composition; adding elements like chromium or copper can significantly reduce or even eliminate magnetism due to altered electron spin interactions. The magnetic permeability and coercivity of nickel alloys differ widely, influencing their suitability for applications in electromagnetic shielding, inductors, and magnetic sensors.

Environmental and Health Considerations

Pure nickel exhibits excellent corrosion resistance and lower toxicity, making it a preferred choice for medical implants and food-grade applications. Nickel alloys, containing elements like chromium or iron, offer enhanced mechanical properties but may introduce environmental concerns due to complex metal extraction and potential allergenic effects. Responsible recycling and proper handling reduce environmental impact and minimize occupational health risks associated with both pure nickel and nickel alloy production.

Selecting the Right Material for Your Project

Pure nickel offers excellent corrosion resistance, high thermal conductivity, and magnetic properties ideal for applications requiring chemical stability and electrical conductivity. Nickel alloys, containing elements like copper, iron, or chromium, provide enhanced mechanical strength, improved oxidation resistance, and tailored properties for high-temperature or structural uses. Selecting between pure nickel and nickel alloys depends on project requirements such as environmental conditions, mechanical stress, and desired performance characteristics.

Pure nickel vs nickel alloy Infographic

materialdif.com

materialdif.com