Sintered nickel offers superior porosity and uniformity, making it ideal for filtration and battery applications, while wrought nickel provides enhanced ductility and strength for structural uses. The sintering process fuses nickel powder without melting, resulting in a porous yet durable material, whereas wrought nickel undergoes mechanical deformation, improving its toughness and corrosion resistance. Choosing between sintered and wrought nickel depends on the specific requirements for permeability, mechanical properties, and end-use performance.

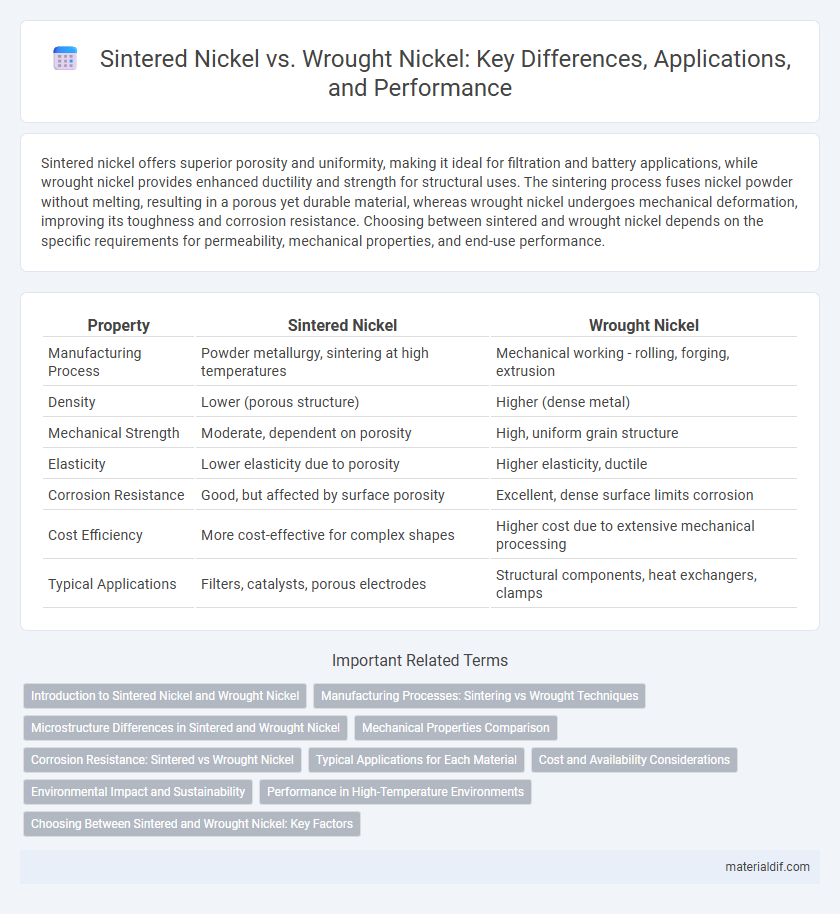

Table of Comparison

| Property | Sintered Nickel | Wrought Nickel |

|---|---|---|

| Manufacturing Process | Powder metallurgy, sintering at high temperatures | Mechanical working - rolling, forging, extrusion |

| Density | Lower (porous structure) | Higher (dense metal) |

| Mechanical Strength | Moderate, dependent on porosity | High, uniform grain structure |

| Elasticity | Lower elasticity due to porosity | Higher elasticity, ductile |

| Corrosion Resistance | Good, but affected by surface porosity | Excellent, dense surface limits corrosion |

| Cost Efficiency | More cost-effective for complex shapes | Higher cost due to extensive mechanical processing |

| Typical Applications | Filters, catalysts, porous electrodes | Structural components, heat exchangers, clamps |

Introduction to Sintered Nickel and Wrought Nickel

Sintered nickel is produced by compacting and heating nickel powder below its melting point, resulting in a porous, strong, and wear-resistant material ideal for filtration and battery electrodes. Wrought nickel is formed through mechanical processes like rolling or extrusion, creating dense, ductile, and malleable sheets or bars used in aerospace and chemical processing industries. Both forms offer distinct microstructures and mechanical properties tailored to specific industrial applications.

Manufacturing Processes: Sintering vs Wrought Techniques

Sintered nickel is produced through a powder metallurgy process where nickel powder is compacted and heated below its melting point, resulting in a porous, high-strength material ideal for filtration and battery electrodes. Wrought nickel undergoes mechanical deformation techniques such as rolling, forging, or extrusion, enhancing its ductility, toughness, and structural uniformity for applications in aerospace and chemical processing. The sintering process allows for complex shapes and tailored porosity, while wrought techniques provide superior grain structure and mechanical properties due to work hardening and recrystallization.

Microstructure Differences in Sintered and Wrought Nickel

Sintered nickel exhibits a porous microstructure due to the powder metallurgy process, resulting in interconnected grain boundaries and voids that enhance certain mechanical and thermal properties. Wrought nickel, formed through deformation and recrystallization, displays a dense, homogeneous microstructure with refined grains and fewer defects, improving ductility and strength. These microstructural differences directly impact their applications, with sintered nickel favored for filtration and catalysis, while wrought nickel is preferred for structural components requiring high toughness.

Mechanical Properties Comparison

Sintered nickel exhibits superior porosity control and wear resistance compared to wrought nickel, making it ideal for applications requiring precise filtration and self-lubrication. Wrought nickel demonstrates higher tensile strength and ductility due to its fully dense microstructure, offering enhanced performance in structural and high-stress environments. Mechanical property variations between sintered and wrought nickel primarily result from differences in processing methods, impacting hardness, tensile strength, and fracture toughness.

Corrosion Resistance: Sintered vs Wrought Nickel

Sintered nickel exhibits enhanced porosity that can increase its surface area, often making it more susceptible to corrosion in aggressive environments compared to wrought nickel. Wrought nickel, with its dense and homogeneous microstructure, offers superior corrosion resistance, especially in acidic and marine applications. The manufacturing process of wrought nickel results in fewer impurities and defects, significantly improving its durability against chemical attack.

Typical Applications for Each Material

Sintered nickel is commonly used in filtration systems, battery electrodes, and catalyst supports due to its porous structure and high surface area, which enhance chemical reactivity and fluid passage. Wrought nickel finds typical applications in aerospace components, electrical resistance wires, and corrosion-resistant structural parts, thanks to its high strength, ductility, and excellent mechanical properties. Both materials serve critical roles in industries demanding specific performance attributes related to temperature resistance and durability.

Cost and Availability Considerations

Sintered nickel typically offers lower production costs due to its powder metallurgy process, making it more cost-effective for complex shapes and high-volume applications. Wrought nickel, produced through rolling or forging, often involves higher material and processing expenses but provides superior mechanical properties and surface finish. Availability of sintered nickel may be more limited depending on powder supply chains, whereas wrought nickel benefits from well-established, global manufacturing networks ensuring consistent supply.

Environmental Impact and Sustainability

Sintered nickel production typically consumes less energy and generates lower greenhouse gas emissions compared to wrought nickel due to its powder metallurgy process, which reduces material waste and machining needs. Wrought nickel, involving extensive forging and rolling, often results in higher resource consumption and environmental footprint due to intense energy requirements and processing stages. Sustainability efforts favor sintered nickel for applications demanding efficient raw material use and reduced environmental impact, supporting circular economy goals in nickel manufacturing.

Performance in High-Temperature Environments

Sintered nickel exhibits superior high-temperature performance due to its porous structure, which enhances heat resistance and oxidation stability compared to wrought nickel. Wrought nickel typically offers greater mechanical strength and ductility, but its non-porous nature limits thermal insulation properties at elevated temperatures. Applications in aerospace and power generation benefit from sintered nickel's enhanced thermal endurance and corrosion resistance under extreme heat conditions.

Choosing Between Sintered and Wrought Nickel: Key Factors

Choosing between sintered and wrought nickel depends largely on the application's mechanical requirements and fabrication complexity. Sintered nickel offers enhanced porosity and wear resistance, making it ideal for specialized filtration and battery electrodes, while wrought nickel provides superior ductility and toughness for structural and aerospace components. Cost considerations and production scale also influence the decision, with sintered nickel typically preferred for precision, small-batch manufacturing and wrought nickel favored in large-scale, high-strength applications.

Sintered Nickel vs Wrought Nickel Infographic

materialdif.com

materialdif.com