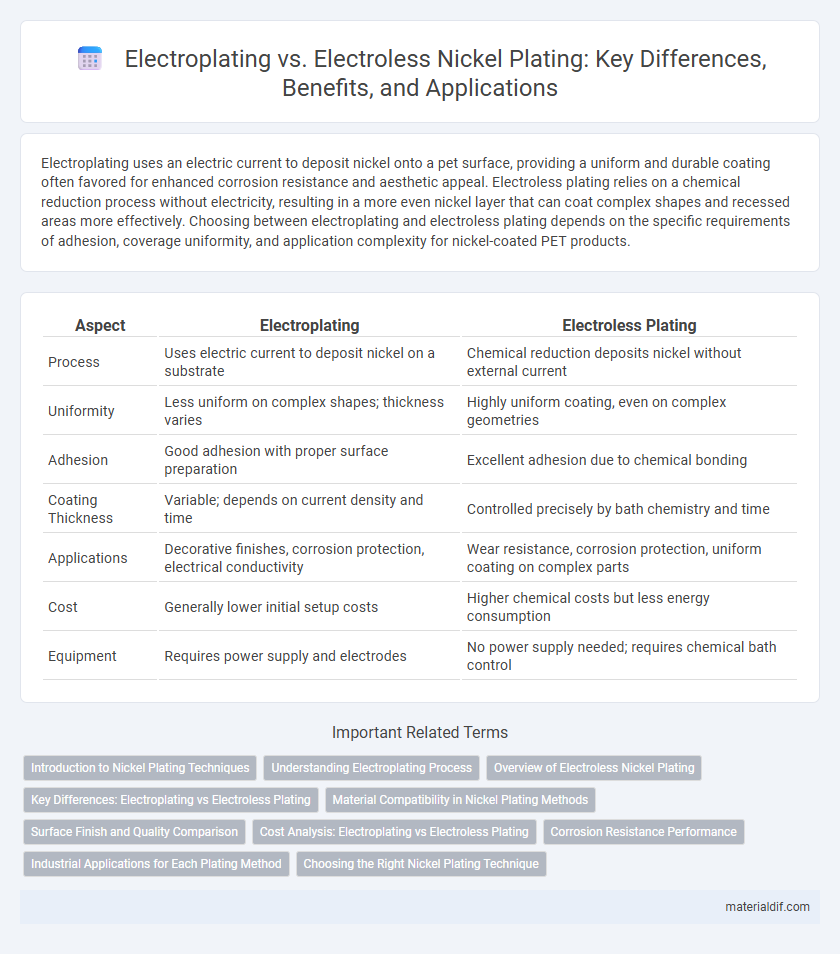

Electroplating uses an electric current to deposit nickel onto a pet surface, providing a uniform and durable coating often favored for enhanced corrosion resistance and aesthetic appeal. Electroless plating relies on a chemical reduction process without electricity, resulting in a more even nickel layer that can coat complex shapes and recessed areas more effectively. Choosing between electroplating and electroless plating depends on the specific requirements of adhesion, coverage uniformity, and application complexity for nickel-coated PET products.

Table of Comparison

| Aspect | Electroplating | Electroless Plating |

|---|---|---|

| Process | Uses electric current to deposit nickel on a substrate | Chemical reduction deposits nickel without external current |

| Uniformity | Less uniform on complex shapes; thickness varies | Highly uniform coating, even on complex geometries |

| Adhesion | Good adhesion with proper surface preparation | Excellent adhesion due to chemical bonding |

| Coating Thickness | Variable; depends on current density and time | Controlled precisely by bath chemistry and time |

| Applications | Decorative finishes, corrosion protection, electrical conductivity | Wear resistance, corrosion protection, uniform coating on complex parts |

| Cost | Generally lower initial setup costs | Higher chemical costs but less energy consumption |

| Equipment | Requires power supply and electrodes | No power supply needed; requires chemical bath control |

Introduction to Nickel Plating Techniques

Nickel plating techniques primarily include electroplating and electroless plating, both used to enhance surface properties such as corrosion resistance and wear durability. Electroplating employs an electric current to deposit nickel ions from a solution onto a conductive substrate, creating a uniform metallic layer. Electroless plating, in contrast, relies on a chemical reduction process without external current, allowing deposition on non-conductive surfaces and complex geometries.

Understanding Electroplating Process

Electroplating uses an electric current to reduce dissolved metal cations and coat a conductive surface with a thin nickel layer, ensuring uniform thickness and enhanced corrosion resistance. The process requires an electrolyte solution containing nickel salts, anodes made of pure nickel, and a cathode where the object is plated. Precise control over voltage, current density, and plating time influences coating quality, adhesion, and thickness in nickel electroplating applications.

Overview of Electroless Nickel Plating

Electroless nickel plating is an autocatalytic chemical process that deposits a uniform nickel-phosphorus or nickel-boron alloy coating without the need for an external electric current. This method provides consistent thickness even on complex geometries, offering excellent corrosion resistance, hardness, and wear protection. Electroless nickel plating is widely used in industries such as aerospace, automotive, and electronics due to its superior adhesion and ability to plate non-conductive surfaces.

Key Differences: Electroplating vs Electroless Plating

Electroplating requires an external electric current to deposit nickel onto a substrate, whereas electroless plating relies on a chemical reduction reaction without electricity. Electroplated nickel coatings often exhibit uniform thickness on conductive materials, while electroless nickel plating provides excellent uniformity on complex shapes and non-conductive surfaces. Corrosion resistance and hardness typically vary between the two methods, with electroless nickel offering enhanced corrosion protection due to phosphorus content in the deposit.

Material Compatibility in Nickel Plating Methods

Electroplating nickel requires a conductive substrate for effective deposition, making it ideal for metals like copper, steel, and aluminum with pre-treatment. Electroless nickel plating offers superior material compatibility, allowing nickel deposition on non-conductive surfaces such as plastics and ceramics through autocatalytic chemical reduction. This makes electroless plating the preferred choice for complex geometries and mixed material assemblies that demand uniform coating thickness and corrosion resistance.

Surface Finish and Quality Comparison

Electroplating nickel delivers a highly uniform and smooth surface finish due to controlled electric current deposition, enhancing corrosion resistance and aesthetic appeal. Electroless nickel plating offers superior coverage on complex geometries and inside recesses, creating a consistent thickness without the need for electrical contact. Both methods provide excellent wear and corrosion resistance, but electroplating typically results in a shinier finish, while electroless plating ensures uniformity and improved hardness across irregular surfaces.

Cost Analysis: Electroplating vs Electroless Plating

Electroplating with nickel generally incurs lower initial setup costs due to simpler equipment and faster processing times, making it cost-effective for high-volume production. Electroless plating, though higher in chemical and maintenance costs, offers uniform coating on complex geometries without requiring an external power source, which can reduce labor expenses. The total cost efficiency depends on application complexity and volume, with electroplating favored for flat surfaces and electroless plating preferred for precision parts and corrosion resistance.

Corrosion Resistance Performance

Electroless plating of nickel provides superior corrosion resistance compared to electroplating due to its uniform and pinhole-free coating that prevents localized corrosion. The autocatalytic process in electroless plating ensures consistent thickness on complex geometries, enhancing protection in aggressive environments. Electroplated nickel, while effective, often exhibits variable thickness and potential defects that can reduce long-term corrosion resistance.

Industrial Applications for Each Plating Method

Electroplating of nickel is widely used in automotive and aerospace industries for corrosion resistance and enhanced surface hardness, relying on an external electric current to deposit a uniform nickel layer on conductive substrates. Electroless nickel plating, preferred in electronics and precision engineering, offers uniform coating thickness on complex geometries without the need for electrical current, improving wear resistance and providing excellent solderability. Both methods enable tailored surface properties, but electroplating excels in high-volume manufacturing with conductive parts, while electroless plating is ideal for non-conductive or intricate components requiring consistent coverage.

Choosing the Right Nickel Plating Technique

Electroplating uses an external electrical current to deposit nickel onto a substrate, providing precise thickness control and superior adhesion, ideal for complex shapes with conductive surfaces. Electroless nickel plating relies on a chemical reduction process, offering uniform coating thickness even on intricate geometries and non-conductive materials, enhancing corrosion resistance and wear properties. Selecting between electroplating and electroless plating depends on the application's requirements for coating uniformity, substrate conductivity, corrosion protection, and cost-effectiveness.

Electroplating vs Electroless Plating Infographic

materialdif.com

materialdif.com