Nickel silver and stainless steel are popular materials in jewelry and pet accessories, prized for their durability and aesthetic appeal. Nickel silver, an alloy of copper, nickel, and zinc, offers a warm, gold-like appearance but may tarnish over time and can cause allergic reactions in sensitive pets. Stainless steel provides superior corrosion resistance, hypoallergenic properties, and a sleek, modern look, making it ideal for long-lasting, low-maintenance pet collars and tags.

Table of Comparison

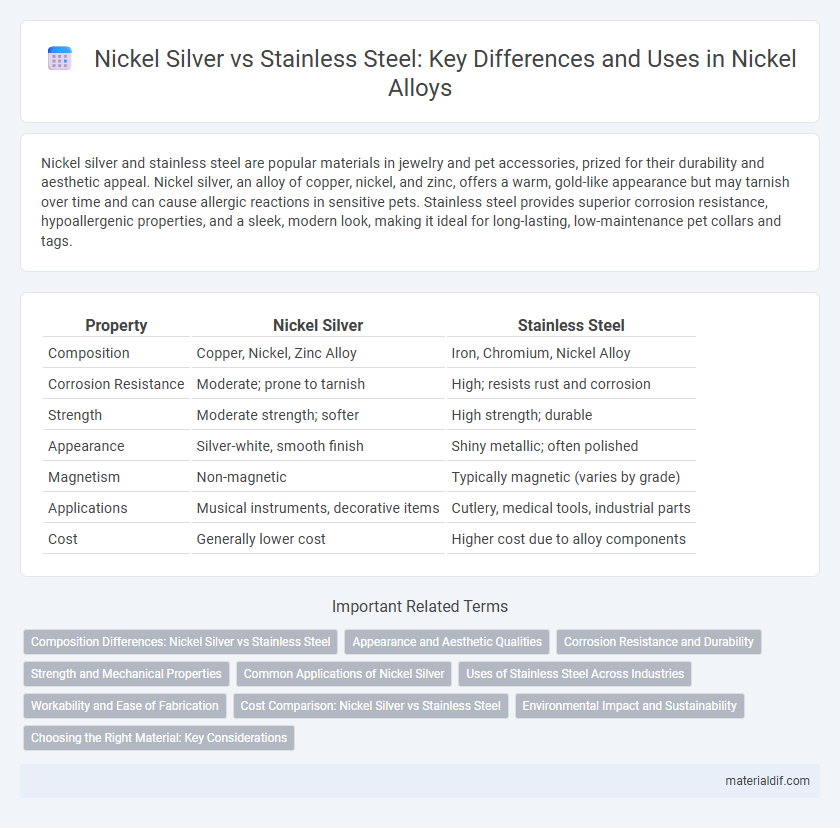

| Property | Nickel Silver | Stainless Steel |

|---|---|---|

| Composition | Copper, Nickel, Zinc Alloy | Iron, Chromium, Nickel Alloy |

| Corrosion Resistance | Moderate; prone to tarnish | High; resists rust and corrosion |

| Strength | Moderate strength; softer | High strength; durable |

| Appearance | Silver-white, smooth finish | Shiny metallic; often polished |

| Magnetism | Non-magnetic | Typically magnetic (varies by grade) |

| Applications | Musical instruments, decorative items | Cutlery, medical tools, industrial parts |

| Cost | Generally lower cost | Higher cost due to alloy components |

Composition Differences: Nickel Silver vs Stainless Steel

Nickel silver is an alloy primarily composed of copper, nickel, and zinc, lacking any actual silver content, while stainless steel mainly consists of iron, chromium, and varying amounts of nickel and carbon. The high copper content in nickel silver gives it a distinctive yellowish hue and enhanced corrosion resistance, whereas stainless steel's chromium content forms a passive oxide layer that prevents rust and offers superior durability. Differences in composition directly impact their respective properties, with nickel silver being favored for decorative applications and stainless steel widely used in structural and cookware purposes due to its strength and resistance to oxidation.

Appearance and Aesthetic Qualities

Nickel silver exhibits a warm, yellowish hue that closely resembles sterling silver, providing a classic and elegant aesthetic often preferred in decorative items and jewelry. Stainless steel, with its cooler, silvery-gray tone, offers a sleek and modern appearance that complements contemporary design trends. Both metals maintain a polished, shiny finish, but nickel silver's subtle gold tint distinguishes it with a vintage, sophisticated look compared to the more industrial, minimalist appeal of stainless steel.

Corrosion Resistance and Durability

Nickel silver exhibits excellent corrosion resistance due to its high nickel content, forming a protective oxide layer that prevents rust and tarnishing in various environments. Stainless steel surpasses nickel silver in durability, offering superior strength and resistance to pitting, crevice corrosion, and oxidation, especially in harsh or acidic conditions. Choosing between these materials depends on the specific application requirements where corrosion resistance or mechanical endurance is prioritized.

Strength and Mechanical Properties

Nickel silver exhibits moderate tensile strength and excellent corrosion resistance, making it suitable for decorative applications but less ideal for heavy-duty mechanical use. Stainless steel offers superior strength, hardness, and durability, with higher resistance to wear and deformation under stress, which enhances its performance in structural and industrial environments. The enhanced mechanical properties of stainless steel result from its alloy composition, primarily iron with chromium and nickel, providing better load-bearing capacity compared to nickel silver.

Common Applications of Nickel Silver

Nickel silver, an alloy composed primarily of copper, nickel, and zinc, is commonly used in applications requiring corrosion resistance and aesthetic appeal, such as musical instruments, jewelry, and cutlery. Its excellent machinability and smooth finish make it ideal for decorative hardware and electrical connectors. Unlike stainless steel, which is favored for high strength and durability in industrial settings, nickel silver is sought after for its non-magnetic properties and attractive silver-like appearance.

Uses of Stainless Steel Across Industries

Stainless steel, an alloy primarily composed of iron, chromium, and nickel, offers superior corrosion resistance and strength, making it indispensable in industries like construction, automotive, and medical equipment manufacturing. Nickel silver, an alloy of copper, nickel, and zinc, lacks the same durability and corrosion resistance, limiting its use mainly to decorative applications and musical instruments. Stainless steel's versatility extends to food processing and chemical industries due to its hygienic surface and resistance to chemical reactions.

Workability and Ease of Fabrication

Nickel silver offers superior workability due to its malleable nature, allowing for easier cutting, bending, and shaping compared to stainless steel. Stainless steel, while more durable, requires specialized tools and techniques for fabrication because of its hardness and resistance to deformation. The choice between nickel silver and stainless steel depends on the complexity of the project and the desired balance between ease of fabrication and material strength.

Cost Comparison: Nickel Silver vs Stainless Steel

Nickel silver generally costs more than stainless steel due to its higher nickel and copper content, making it a premium choice for decorative and musical applications. Stainless steel is more cost-effective, offering excellent durability and corrosion resistance at a lower price point, widely used in industrial and kitchenware products. The price difference is influenced by raw material costs, manufacturing complexity, and intended product use.

Environmental Impact and Sustainability

Nickel silver, an alloy of copper, nickel, and zinc, poses greater environmental challenges due to the mining and refining processes of its constituent metals, which often involve higher energy consumption and habitat disruption compared to stainless steel. Stainless steel, primarily composed of iron, chromium, and nickel, offers superior recyclability and durability, significantly reducing waste and resource depletion over its lifecycle. The sustainability of stainless steel is further enhanced by its extensive recycling infrastructure, which lowers environmental impact through repeated reuse of scrap material.

Choosing the Right Material: Key Considerations

Nickel silver offers superior corrosion resistance and a smooth, polished appearance, making it ideal for decorative applications and musical instruments. Stainless steel provides greater strength, durability, and resistance to tarnishing, favored in kitchenware and industrial uses. Selecting between nickel silver and stainless steel depends on the specific requirements for corrosion resistance, mechanical strength, and aesthetic appeal.

Nickel silver vs stainless steel Infographic

materialdif.com

materialdif.com