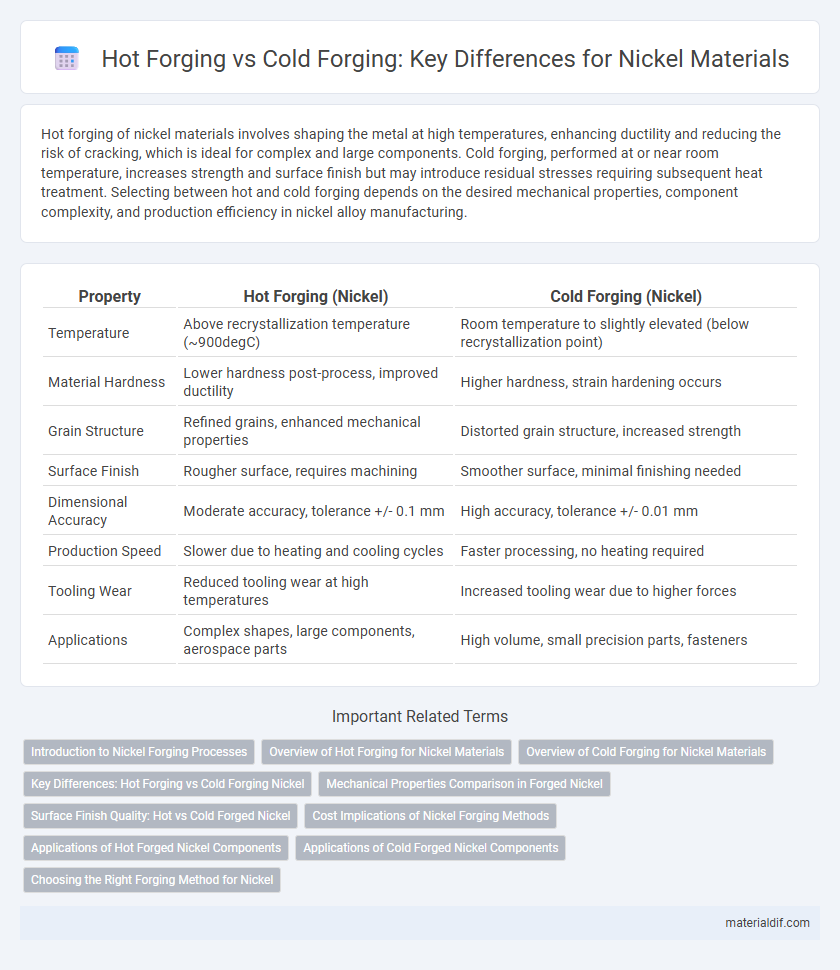

Hot forging of nickel materials involves shaping the metal at high temperatures, enhancing ductility and reducing the risk of cracking, which is ideal for complex and large components. Cold forging, performed at or near room temperature, increases strength and surface finish but may introduce residual stresses requiring subsequent heat treatment. Selecting between hot and cold forging depends on the desired mechanical properties, component complexity, and production efficiency in nickel alloy manufacturing.

Table of Comparison

| Property | Hot Forging (Nickel) | Cold Forging (Nickel) |

|---|---|---|

| Temperature | Above recrystallization temperature (~900degC) | Room temperature to slightly elevated (below recrystallization point) |

| Material Hardness | Lower hardness post-process, improved ductility | Higher hardness, strain hardening occurs |

| Grain Structure | Refined grains, enhanced mechanical properties | Distorted grain structure, increased strength |

| Surface Finish | Rougher surface, requires machining | Smoother surface, minimal finishing needed |

| Dimensional Accuracy | Moderate accuracy, tolerance +/- 0.1 mm | High accuracy, tolerance +/- 0.01 mm |

| Production Speed | Slower due to heating and cooling cycles | Faster processing, no heating required |

| Tooling Wear | Reduced tooling wear at high temperatures | Increased tooling wear due to higher forces |

| Applications | Complex shapes, large components, aerospace parts | High volume, small precision parts, fasteners |

Introduction to Nickel Forging Processes

Nickel forging involves shaping nickel alloys under different temperature conditions, where hot forging occurs above the metal's recrystallization temperature, enhancing ductility and reducing work hardening. Cold forging is performed at or near room temperature, increasing strength through strain hardening but requiring greater force and risk of cracking. Selecting the appropriate forging method depends on the desired mechanical properties and application, with hot forging typically used for complex shapes and cold forging preferred for precision components.

Overview of Hot Forging for Nickel Materials

Hot forging of nickel materials involves shaping the metal at temperatures typically above 900degC, enhancing ductility and reducing deformation resistance. This process refines the microstructure, improving mechanical properties such as tensile strength and fatigue resistance, which are critical in aerospace and power generation applications. Controlling the temperature and deformation rate during hot forging ensures optimal grain flow and minimizes defects, resulting in superior component performance.

Overview of Cold Forging for Nickel Materials

Cold forging of nickel materials enhances mechanical properties such as strength, hardness, and fatigue resistance by deforming the metal below its recrystallization temperature. This process produces precise, uniform shapes with superior surface finish and minimal material waste compared to hot forging. Cold forging is especially advantageous for nickel alloys used in aerospace and automotive industries, where dimensional accuracy and surface integrity are critical.

Key Differences: Hot Forging vs Cold Forging Nickel

Hot forging nickel involves shaping the metal above its recrystallization temperature, enhancing ductility and reducing deformation resistance, which results in improved grain structure and mechanical properties. Cold forging nickel is performed at or near room temperature, increasing strength through strain hardening but may lead to residual stresses and lower ductility. The choice between hot and cold forging nickel depends on desired mechanical performance, surface finish requirements, and the specific application of the nickel alloy components.

Mechanical Properties Comparison in Forged Nickel

Hot forging of nickel enhances its ductility and toughness by refining the grain structure through recrystallization, resulting in improved impact resistance and uniform mechanical properties. Cold forging increases strength and hardness due to strain hardening but may reduce ductility and increase residual stresses, making the material more brittle. The choice between hot and cold forging directly influences tensile strength, yield strength, and elongation in forged nickel components, with hot forging favoring toughness and cold forging emphasizing strength.

Surface Finish Quality: Hot vs Cold Forged Nickel

Cold forging nickel produces superior surface finish quality due to lower oxidation and minimal scale formation, resulting in smoother, cleaner surfaces ideal for precision applications. Hot forging, while enabling easier deformation of nickel alloys, often leads to rougher finishes caused by high-temperature scale and surface oxidation. Choosing cold forging optimizes surface integrity for nickel components requiring high corrosion resistance and aesthetic appearance.

Cost Implications of Nickel Forging Methods

Cold forging of nickel is generally more cost-effective due to lower energy consumption and reduced need for extensive machining, resulting in less material waste. Hot forging, while more expensive because of higher energy requirements and specialized equipment, allows for greater ductility and complex shapes, which can reduce downstream processing expenses. Choosing between the two methods depends on balancing upfront forging costs against the potential savings in material performance and manufacturing efficiency.

Applications of Hot Forged Nickel Components

Hot forged nickel components exhibit superior high-temperature strength and corrosion resistance, making them ideal for aerospace turbine blades, chemical processing equipment, and power generation systems. The hot forging process refines the grain structure of nickel alloys, enhancing mechanical properties crucial for extreme environments. These applications benefit from improved fatigue life and dimensional stability compared to cold forged counterparts.

Applications of Cold Forged Nickel Components

Cold forged nickel components exhibit superior strength, improved surface finish, and enhanced dimensional accuracy, making them ideal for aerospace fasteners, medical instruments, and electrical connectors. The cold forging process refines the grain structure of nickel, increasing fatigue resistance and corrosion durability critical for high-performance environments. Applications benefit from reduced machining costs and consistent mechanical properties essential in precision industries.

Choosing the Right Forging Method for Nickel

Hot forging of nickel involves shaping the metal above its recrystallization temperature, enhancing ductility and reducing internal stresses, making it ideal for complex geometries and large components. Cold forging preserves surface finish and improves dimensional accuracy but may increase work hardening and require subsequent heat treatment for nickel alloys. Selecting between hot and cold forging depends on the desired mechanical properties, component size, and production efficiency in nickel manufacturing.

Hot forging vs cold forging (nickel materials) Infographic

materialdif.com

materialdif.com