Ferromagnetic nickel exhibits strong magnetic properties due to its unpaired electrons, making it ideal for applications in magnetic storage, electric motors, and sensors. Nonmagnetic nickel, in contrast, lacks this magnetic behavior and is commonly used in corrosion-resistant alloys, stainless steel production, and plating to enhance durability and appearance. Understanding the distinction between ferromagnetic and nonmagnetic nickel is crucial for selecting the appropriate material in industrial and technological applications.

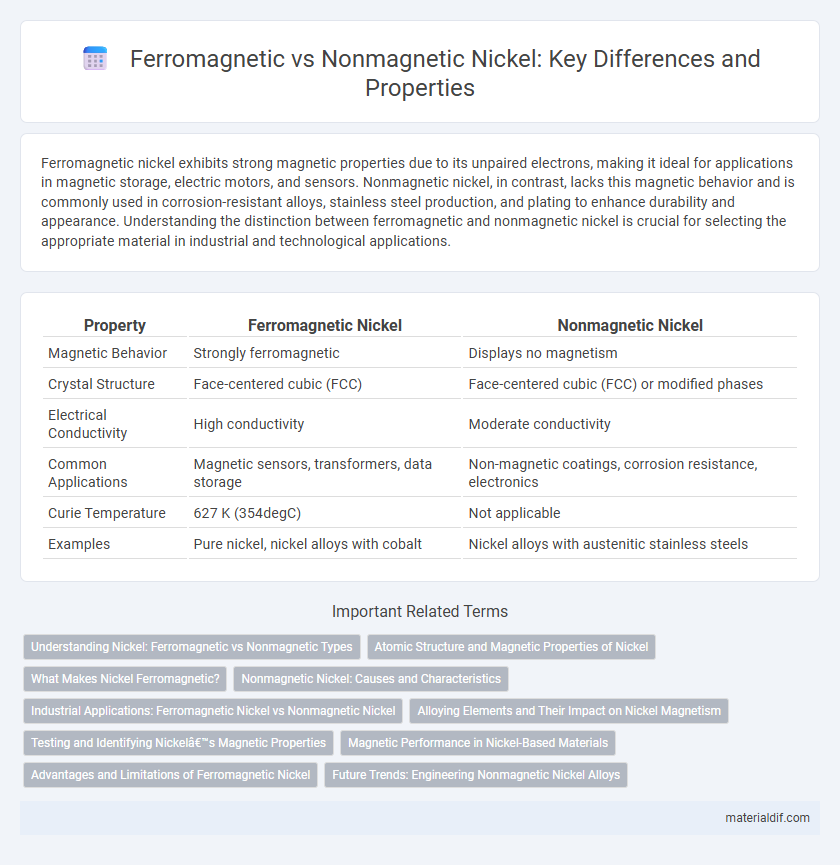

Table of Comparison

| Property | Ferromagnetic Nickel | Nonmagnetic Nickel |

|---|---|---|

| Magnetic Behavior | Strongly ferromagnetic | Displays no magnetism |

| Crystal Structure | Face-centered cubic (FCC) | Face-centered cubic (FCC) or modified phases |

| Electrical Conductivity | High conductivity | Moderate conductivity |

| Common Applications | Magnetic sensors, transformers, data storage | Non-magnetic coatings, corrosion resistance, electronics |

| Curie Temperature | 627 K (354degC) | Not applicable |

| Examples | Pure nickel, nickel alloys with cobalt | Nickel alloys with austenitic stainless steels |

Understanding Nickel: Ferromagnetic vs Nonmagnetic Types

Ferromagnetic nickel exhibits strong magnetic properties due to its unpaired electrons and ordered atomic structure, making it essential in electromagnetic applications and data storage devices. Nonmagnetic nickel, often found in alloys or chemically modified forms, lacks this magnetic ordering and is preferred in corrosion-resistant coatings and non-magnetic industrial components. Understanding the distinction between ferromagnetic and nonmagnetic nickel aids in selecting the appropriate nickel type for specific technological and manufacturing needs.

Atomic Structure and Magnetic Properties of Nickel

Ferromagnetic nickel exhibits a face-centered cubic (FCC) atomic structure with unpaired 3d electrons that produce strong magnetic moments, resulting in spontaneous magnetization below its Curie temperature of 627 K. Nonmagnetic nickel forms in metastable phases or in alloys where electron pairing or lattice distortions suppress magnetic ordering, disrupting the alignment of magnetic moments. The intrinsic electron configuration in ferromagnetic nickel features partially filled 3d orbitals, which facilitate exchange interactions responsible for its robust magnetic properties, unlike nonmagnetic phases where these interactions are diminished or absent.

What Makes Nickel Ferromagnetic?

Nickel exhibits ferromagnetism due to the alignment of its unpaired 3d electrons, which create a spontaneous magnetic moment. The exchange interaction between these electrons causes parallel spin alignment, resulting in a strong, permanent magnetic field. In contrast, nonmagnetic nickel lacks this electron spin alignment, preventing the formation of a significant magnetic moment.

Nonmagnetic Nickel: Causes and Characteristics

Nonmagnetic nickel arises primarily from its crystallographic structure, specifically the face-centered cubic (FCC) phase stabilized at elevated temperatures or through alloying elements like copper and manganese. This phase exhibits paramagnetic behavior due to electron spin configurations that do not support spontaneous magnetization, contrasting with the ferromagnetic body-centered cubic (BCC) or hexagonal close-packed (HCP) forms. Nonmagnetic nickel is characterized by high corrosion resistance, excellent electrical conductivity, and enhanced ductility, making it valuable in applications requiring stable magnetic neutrality.

Industrial Applications: Ferromagnetic Nickel vs Nonmagnetic Nickel

Ferromagnetic nickel, with its strong magnetic properties, is extensively used in electromagnetic devices, transformers, and magnetic storage media where magnetic responsiveness is critical. Nonmagnetic nickel, often alloyed with elements like chromium in stainless steel, is favored in chemical processing, aerospace, and food industry applications due to its corrosion resistance and mechanical strength without magnetic interference. Industrial applications exploit ferromagnetic nickel for magnetic sensors and actuators, while nonmagnetic nickel alloys excel in environments requiring nonmagnetic materials to prevent magnetic field disturbances.

Alloying Elements and Their Impact on Nickel Magnetism

Ferromagnetic nickel maintains its magnetic properties primarily due to the presence of unpaired 3d electrons, which are influenced by alloying elements such as cobalt and iron that enhance its magnetic moment. Nonmagnetic nickel alloys often contain elements like copper, manganese, and chromium, which disrupt the magnetic ordering by altering electron configurations and reducing exchange interactions. The introduction of these alloying elements modifies the crystal structure and electron density, directly impacting the magnetic behavior of nickel-based materials.

Testing and Identifying Nickel’s Magnetic Properties

Testing nickel's magnetic properties involves using a magnetometer or a simple magnet to distinguish ferromagnetic nickel, which exhibits strong attraction, from nonmagnetic nickel alloys that show little to no magnetic response. Precise identification can be achieved through techniques like vibrating sample magnetometry (VSM) or superconducting quantum interference device (SQUID) measurements, which quantify magnetic susceptibility and coercivity. Magnetic characterization is crucial in applications such as electronics and catalysis, where specific magnetic behaviors dictate performance and material selection.

Magnetic Performance in Nickel-Based Materials

Ferromagnetic nickel exhibits strong magnetic performance due to its unpaired electrons and crystalline structure, making it ideal for applications in magnetic sensors and memory devices. In contrast, nonmagnetic nickel, often achieved through alloying or nanostructuring, shows diminished or no magnetic response, suitable for corrosion resistance and catalytic purposes. Understanding the magnetic behavior of nickel-based materials is crucial for optimizing their performance in electronic, industrial, and technological applications.

Advantages and Limitations of Ferromagnetic Nickel

Ferromagnetic nickel exhibits strong magnetic properties essential for applications in electric motors, transformers, and magnetic storage devices due to its high magnetic permeability and coercivity. Its advantages include efficient magnetic flux conduction and enhanced electromagnetic performance, while limitations involve susceptibility to corrosion and reduced effectiveness at elevated temperatures. Nonmagnetic nickel lacks these magnetic benefits but offers superior corrosion resistance and stability in high-temperature environments, making it preferable where magnetism is undesired.

Future Trends: Engineering Nonmagnetic Nickel Alloys

Future trends in engineering nonmagnetic nickel alloys emphasize enhancing corrosion resistance, mechanical strength, and thermal stability for advanced aerospace and electronic applications. Researchers are exploring precise alloying with elements like chromium, molybdenum, and copper to tailor magnetic properties without compromising conductivity or durability. Innovations in additive manufacturing and nanoscale engineering enable the production of customized nonmagnetic nickel components, driving performance in critical, high-tech industries.

Ferromagnetic nickel vs Nonmagnetic nickel Infographic

materialdif.com

materialdif.com