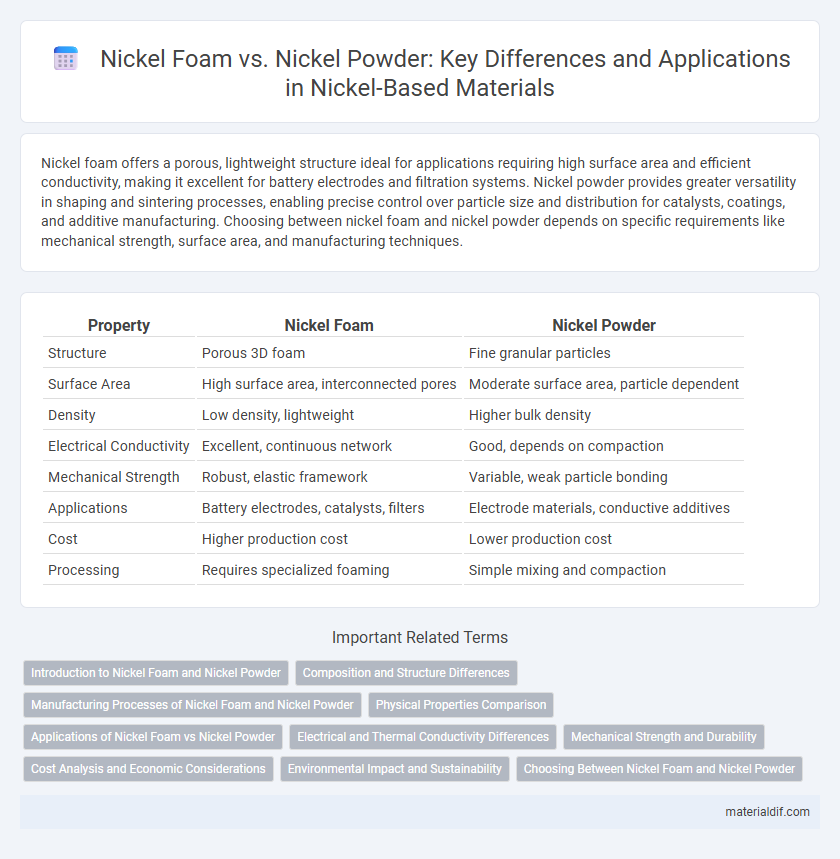

Nickel foam offers a porous, lightweight structure ideal for applications requiring high surface area and efficient conductivity, making it excellent for battery electrodes and filtration systems. Nickel powder provides greater versatility in shaping and sintering processes, enabling precise control over particle size and distribution for catalysts, coatings, and additive manufacturing. Choosing between nickel foam and nickel powder depends on specific requirements like mechanical strength, surface area, and manufacturing techniques.

Table of Comparison

| Property | Nickel Foam | Nickel Powder |

|---|---|---|

| Structure | Porous 3D foam | Fine granular particles |

| Surface Area | High surface area, interconnected pores | Moderate surface area, particle dependent |

| Density | Low density, lightweight | Higher bulk density |

| Electrical Conductivity | Excellent, continuous network | Good, depends on compaction |

| Mechanical Strength | Robust, elastic framework | Variable, weak particle bonding |

| Applications | Battery electrodes, catalysts, filters | Electrode materials, conductive additives |

| Cost | Higher production cost | Lower production cost |

| Processing | Requires specialized foaming | Simple mixing and compaction |

Introduction to Nickel Foam and Nickel Powder

Nickel foam is a porous, three-dimensional structure with high surface area, widely used in batteries and catalysts for improved conductivity and durability. Nickel powder consists of fine particles of elemental nickel, commonly employed in metal injection molding, coatings, and as a catalyst due to its high reactivity and surface contact. Both forms of nickel serve crucial roles in industrial applications, with foam providing structural support and powder enabling chemical activity.

Composition and Structure Differences

Nickel foam consists of a porous, three-dimensional matrix with interconnected pores, providing a high surface area and lightweight structure, whereas nickel powder is composed of fine, discrete particles with a high specific surface area but lacks structural connectivity. The foam's open-cell structure enhances mechanical strength and fluid flow, making it ideal for battery electrodes and catalysis, while nickel powder offers versatility in metallurgy and coatings due to its granular form. Differences in porosity and morphology significantly affect their electrical conductivity and reactivity in various industrial applications.

Manufacturing Processes of Nickel Foam and Nickel Powder

Nickel foam is manufactured through a chemical vapor deposition or electroplating process, where nickel is deposited onto a porous template that is later removed, creating a lightweight and highly porous structure ideal for battery electrodes and catalysts. Nickel powder is produced by chemical reduction, atomization, or electrolysis methods, resulting in fine particles used in powder metallurgy, battery anodes, and coatings. The manufacturing process for nickel foam emphasizes porosity and interconnected networks, while nickel powder production focuses on particle size control and purity for diverse industrial applications.

Physical Properties Comparison

Nickel foam exhibits a porous, three-dimensional structure with high surface area and low density, making it lightweight and ideal for applications requiring enhanced electron conductivity and mechanical flexibility. In contrast, nickel powder consists of fine granules with higher density and lower porosity, offering larger surface area per unit weight but limited mechanical strength. The distinct physical properties influence their suitability in catalysis, battery electrodes, and filtration systems based on the required conductivity, surface exposure, and structural integrity.

Applications of Nickel Foam vs Nickel Powder

Nickel foam is widely used in battery electrodes, fuel cells, and filtration systems due to its porous structure that offers high surface area and excellent conductivity. Nickel powder is preferred in powder metallurgy, catalyst production, and additive manufacturing for its fine particle size and ability to form uniform composites. Both materials serve crucial roles in energy storage and catalysis but differ in form and specific application versatility.

Electrical and Thermal Conductivity Differences

Nickel foam exhibits higher electrical conductivity due to its porous structure allowing enhanced electron flow and better thermal conductivity by facilitating heat dissipation through interconnected voids. Nickel powder, while having a larger surface area, generally shows lower electrical and thermal conductivity as particle boundaries impede electron and heat transfer. For applications requiring efficient current and heat management, nickel foam outperforms nickel powder.

Mechanical Strength and Durability

Nickel foam exhibits superior mechanical strength and durability compared to nickel powder due to its porous, three-dimensional structure that distributes stress more evenly. The interconnected network in nickel foam enhances resistance to deformation and mechanical fatigue, making it ideal for applications requiring structural integrity under repetitive loading. In contrast, nickel powder, while offering high surface area, is prone to compaction and particle degradation, limiting its mechanical robustness and longevity.

Cost Analysis and Economic Considerations

Nickel foam typically incurs higher initial costs compared to nickel powder due to complex manufacturing processes involving template synthesis and controlled pore formation. Cost analysis reveals nickel powder's advantage in bulk applications, benefiting from economies of scale and lower material consumption per unit volume. Economic considerations also factor in lifecycle performance, where nickel foam's structural durability can offset upfront expenses in specialized applications like battery electrodes or catalysts.

Environmental Impact and Sustainability

Nickel foam offers enhanced recyclability compared to nickel powder due to its structured porous design, which facilitates easier collection and reuse in industrial processes. The production of nickel foam generally consumes less energy and generates fewer emissions than the powder manufacturing process, reducing its overall environmental footprint. Nickel powder, while versatile, poses greater challenges in handling and containment, increasing the risk of metal dust pollution and environmental contamination during production and disposal.

Choosing Between Nickel Foam and Nickel Powder

Choosing between nickel foam and nickel powder depends on the application's conductivity, surface area, and structural requirements. Nickel foam offers a continuous porous structure ideal for high-surface-area electrochemical applications like batteries and fuel cells, providing excellent electron transport and mechanical stability. In contrast, nickel powder is preferred for sintering, catalysis, or additives due to its controlled particle size and enhanced reactivity but lacks the cohesive framework that nickel foam provides.

Nickel Foam vs Nickel Powder Infographic

materialdif.com

materialdif.com