Wet nickel plating involves immersing the metal object in a nickel-containing electrolyte solution, resulting in a uniform, corrosion-resistant coating with excellent adhesion and smooth finish. Dry nickel plating, often conducted through physical vapor deposition (PVD), applies nickel in a vacuum environment, producing a harder, wear-resistant layer ideal for precision parts requiring fine detailing. Choosing between wet and dry nickel plating depends on the desired thickness, durability, and application environment of the coated component.

Table of Comparison

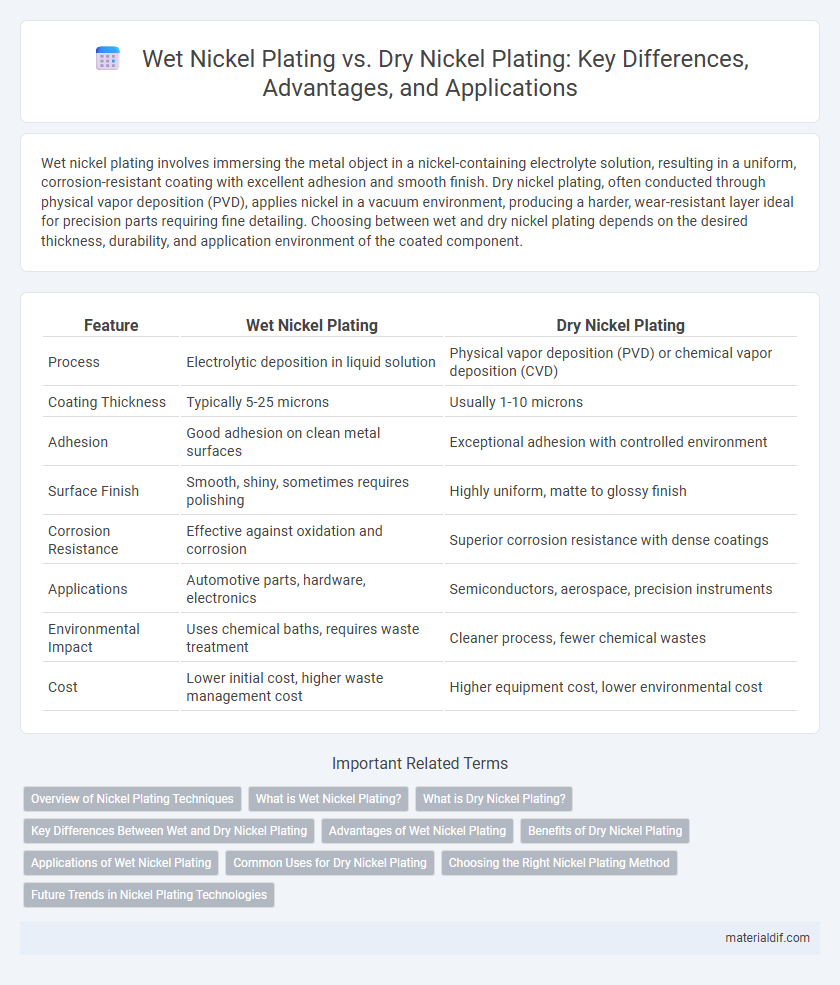

| Feature | Wet Nickel Plating | Dry Nickel Plating |

|---|---|---|

| Process | Electrolytic deposition in liquid solution | Physical vapor deposition (PVD) or chemical vapor deposition (CVD) |

| Coating Thickness | Typically 5-25 microns | Usually 1-10 microns |

| Adhesion | Good adhesion on clean metal surfaces | Exceptional adhesion with controlled environment |

| Surface Finish | Smooth, shiny, sometimes requires polishing | Highly uniform, matte to glossy finish |

| Corrosion Resistance | Effective against oxidation and corrosion | Superior corrosion resistance with dense coatings |

| Applications | Automotive parts, hardware, electronics | Semiconductors, aerospace, precision instruments |

| Environmental Impact | Uses chemical baths, requires waste treatment | Cleaner process, fewer chemical wastes |

| Cost | Lower initial cost, higher waste management cost | Higher equipment cost, lower environmental cost |

Overview of Nickel Plating Techniques

Wet nickel plating involves immersing the substrate in a liquid electrolyte containing nickel salts, enabling uniform metal deposition through electrochemical reactions that provide excellent corrosion resistance and wear properties. Dry nickel plating, often referred to as physical vapor deposition (PVD), uses vacuum-based techniques to deposit nickel atoms as a thin film onto surfaces, offering superior hardness, precise thickness control, and enhanced decorative finishes. Both methods are essential in industries like automotive, electronics, and aerospace, chosen based on required coating characteristics such as thickness, adhesion, and environmental impact.

What is Wet Nickel Plating?

Wet nickel plating is an electrochemical process where a metal object is submerged in a liquid bath containing nickel salts and subjected to an electric current, causing nickel ions to deposit evenly on the surface. This method provides excellent corrosion resistance and a uniform, smooth finish ideal for complex shapes and delicate components. It differs from dry nickel plating by using an aqueous solution rather than vapor or gas-phase deposition techniques.

What is Dry Nickel Plating?

Dry nickel plating is an electroplating process where nickel is deposited onto a surface without the use of liquid electrolytes, often utilizing vapor or plasma techniques. This method provides superior corrosion resistance, uniform coating thickness, and enhanced hardness compared to traditional wet nickel plating. Common applications for dry nickel plating include aerospace components, electronic devices, and precision instruments requiring high purity and controlled surface properties.

Key Differences Between Wet and Dry Nickel Plating

Wet nickel plating involves immersing the substrate in an electrolyte solution where nickel ions are deposited through electrochemical reactions, ensuring uniform coating thickness and enhanced corrosion resistance. Dry nickel plating, often referred to as physical vapor deposition (PVD), deposits nickel in a vacuum chamber by vaporizing nickel material, resulting in a hard, wear-resistant surface with superior adhesion on complex geometries. Key differences include wet plating's reliance on liquid electrolytes for conductivity versus dry plating's vacuum environment, as well as variations in coating properties, environmental impact, and process control.

Advantages of Wet Nickel Plating

Wet nickel plating offers superior corrosion resistance due to the uniform deposition of nickel ions, enhancing the durability of metal substrates in harsh environments. This method provides excellent adhesion on complex geometries and intricate surfaces, ensuring comprehensive coverage that dry plating methods may lack. Wet nickel plating also enables precise thickness control, resulting in consistent coating quality critical for industrial applications requiring high-performance protective layers.

Benefits of Dry Nickel Plating

Dry nickel plating offers superior corrosion resistance and uniform coating thickness compared to wet nickel plating, making it ideal for precision applications in aerospace and electronics. Its environmentally friendly process reduces wastewater and chemical waste, enhancing sustainability in manufacturing. Additionally, dry plating improves adhesion and surface hardness, extending the lifespan of metal components in demanding conditions.

Applications of Wet Nickel Plating

Wet nickel plating is widely used in automotive and aerospace industries due to its excellent corrosion resistance and uniform coating on complex geometries. It provides superior adhesion and enhanced surface hardness, making it ideal for electrical connectors, decorative finishes, and precision components. Its ability to deposit evenly on intricate parts ensures durability in harsh environments and consistent performance in electronic and industrial applications.

Common Uses for Dry Nickel Plating

Dry nickel plating is frequently used in electronics for enhancing corrosion resistance and electrical conductivity on connectors and circuit boards. It is also common in aerospace applications where thin, uniform coatings improve wear resistance without adding significant weight. Industrial machinery components benefit from dry nickel plating by achieving superior hardness and increased durability in high-stress environments.

Choosing the Right Nickel Plating Method

Wet nickel plating involves immersing components in a liquid electrolyte solution, providing uniform coating thickness and excellent corrosion resistance, which is ideal for complex geometries. Dry nickel plating, typically performed using physical vapor deposition (PVD) or electro-less techniques, offers superior hardness and wear resistance, making it suitable for high-performance aerospace and automotive parts. Selecting the right nickel plating method depends on factors such as the required corrosion protection, surface durability, part complexity, and production volume to optimize cost-efficiency and performance.

Future Trends in Nickel Plating Technologies

Emerging advancements in nickel plating technologies emphasize eco-friendly and energy-efficient processes, with wet nickel plating evolving to incorporate more sustainable electrolytes and waste reduction techniques. Dry nickel plating, including vacuum-based methods like electroless plating and physical vapor deposition (PVD), continues to gain traction for providing superior corrosion resistance and uniform coatings crucial in aerospace and electronics industries. Future trends predict integration of nanostructured nickel coatings and AI-driven process controls to enhance precision, performance, and resource conservation in nickel plating applications.

Wet Nickel Plating vs Dry Nickel Plating Infographic

materialdif.com

materialdif.com