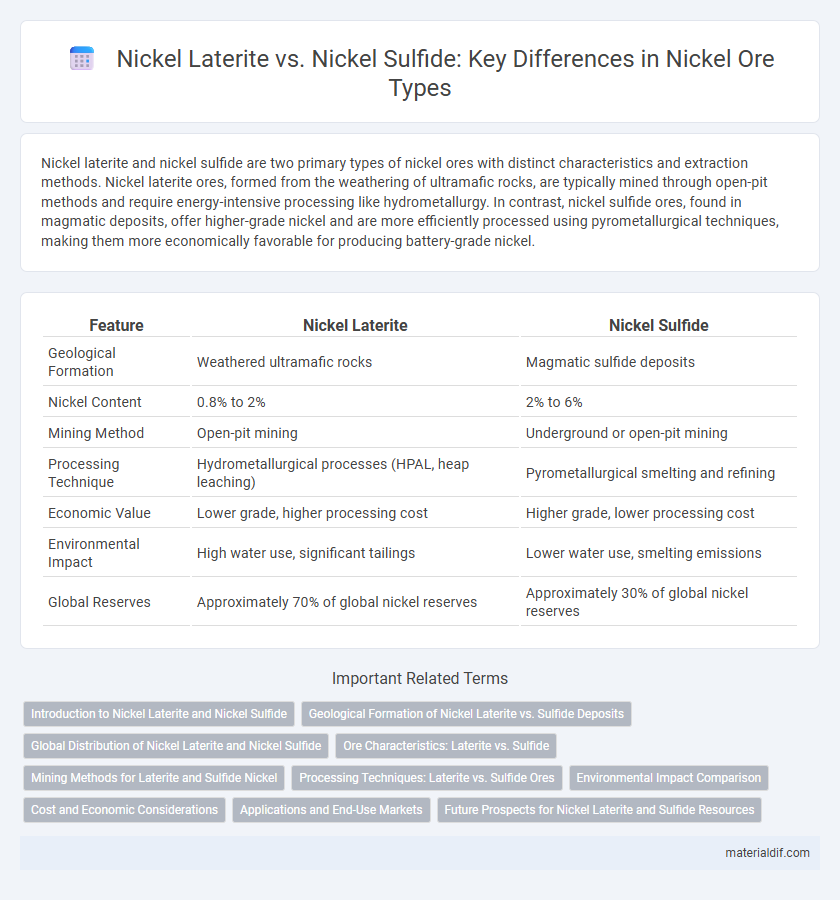

Nickel laterite and nickel sulfide are two primary types of nickel ores with distinct characteristics and extraction methods. Nickel laterite ores, formed from the weathering of ultramafic rocks, are typically mined through open-pit methods and require energy-intensive processing like hydrometallurgy. In contrast, nickel sulfide ores, found in magmatic deposits, offer higher-grade nickel and are more efficiently processed using pyrometallurgical techniques, making them more economically favorable for producing battery-grade nickel.

Table of Comparison

| Feature | Nickel Laterite | Nickel Sulfide |

|---|---|---|

| Geological Formation | Weathered ultramafic rocks | Magmatic sulfide deposits |

| Nickel Content | 0.8% to 2% | 2% to 6% |

| Mining Method | Open-pit mining | Underground or open-pit mining |

| Processing Technique | Hydrometallurgical processes (HPAL, heap leaching) | Pyrometallurgical smelting and refining |

| Economic Value | Lower grade, higher processing cost | Higher grade, lower processing cost |

| Environmental Impact | High water use, significant tailings | Lower water use, smelting emissions |

| Global Reserves | Approximately 70% of global nickel reserves | Approximately 30% of global nickel reserves |

Introduction to Nickel Laterite and Nickel Sulfide

Nickel laterite deposits form from the weathering of ultramafic rocks and contain nickel primarily in oxide minerals, making them abundant but more challenging to process than nickel sulfide ores. Nickel sulfide deposits, often originating from magmatic processes, contain nickel within sulfide minerals, offering higher nickel grades and more straightforward extraction through pyrometallurgical methods. Understanding the geological formation and mineralogy of these two nickel ore types is crucial for optimizing mining and refining strategies.

Geological Formation of Nickel Laterite vs. Sulfide Deposits

Nickel laterite deposits form through intense weathering of ultramafic rocks in tropical climates, resulting in the concentration of nickel in the oxide-rich soil profile. Nickel sulfide deposits originate from magmatic processes, where nickel is concentrated by hydrothermal fluids within mafic and ultramafic igneous rocks. Laterite deposits are typically found near the surface, while sulfide deposits are often located deeper in the Earth's crust.

Global Distribution of Nickel Laterite and Nickel Sulfide

Nickel laterite deposits dominate global nickel resources, accounting for approximately 70% of known reserves, primarily found in tropical regions such as Indonesia, the Philippines, and New Caledonia. Nickel sulfide deposits, which make up about 30% of global reserves, are predominantly located in countries like Canada, Russia, and Australia, often associated with ultramafic and mafic rock formations. The contrasting geographic distribution influences mining strategies, processing techniques, and market dynamics within the nickel industry.

Ore Characteristics: Laterite vs. Sulfide

Nickel laterite ores are primarily composed of oxides and hydroxides, exhibiting high iron and manganese content with low sulfur levels, while nickel sulfide ores contain nickel combined with sulfur and often feature associated minerals like pyrrhotite and pentlandite. Laterite deposits form primarily through intense weathering in tropical climates, resulting in a layered profile including limonite, saprolite, and garnierite zones, whereas sulfide deposits typically originate from magmatic or hydrothermal processes with more concentrated and higher-grade nickel content. The mineralogical differences affect processing methods significantly; laterites require energy-intensive hydrometallurgical or pyrometallurgical treatments, whereas sulfides are more amenable to conventional flotation and smelting techniques.

Mining Methods for Laterite and Sulfide Nickel

Nickel laterite mining predominantly uses open-pit methods due to the ore's near-surface location and extensive lateral spread, allowing for large-scale extraction with lower operational costs. In contrast, nickel sulfide deposits, often located deeper underground, require underground mining techniques such as block caving or cut-and-fill, which target high-grade veins with greater selectivity and lower waste extraction. Processing laterite ores involves energy-intensive pyrometallurgical or hydrometallurgical routes, while sulfide ores are typically processed by froth flotation followed by smelting, reflecting the different mineralogical characteristics and economic considerations.

Processing Techniques: Laterite vs. Sulfide Ores

Nickel laterite ores require energy-intensive hydrometallurgical processes such as high-pressure acid leaching (HPAL) or atmospheric leaching to extract nickel due to their complex mineralogy and high iron content. In contrast, nickel sulfide ores undergo smelting and flotation techniques that leverage their higher nickel grades and simpler mineral structures, resulting in more cost-effective and environmentally manageable extraction. The choice of processing technique directly impacts recovery rates, operational costs, and environmental footprint in nickel production.

Environmental Impact Comparison

Nickel laterite mining generates significant environmental concerns due to extensive land disturbance, high water consumption, and acidic runoff that can contaminate local ecosystems. In contrast, nickel sulfide mining generally produces less surface disruption and lower greenhouse gas emissions because of more concentrated ore bodies and underground extraction methods. Both types of mining require comprehensive rehabilitation plans, but nickel sulfide operations often have a reduced footprint and less severe ecological impact overall.

Cost and Economic Considerations

Nickel laterite deposits generally incur higher extraction and processing costs compared to nickel sulfide due to their complex metallurgy and the need for energy-intensive techniques like high-pressure acid leaching (HPAL). Nickel sulfide ores offer lower production costs and higher-grade concentrates, making them more economically attractive for traditional smelting and refining methods. Market fluctuations and environmental regulations also influence the economic viability of both ore types, with laterite projects often requiring larger capital investments and longer development timelines.

Applications and End-Use Markets

Nickel laterite ores primarily supply the stainless steel industry, accounting for over 70% of nickel consumption due to their high iron content and suitability for large-scale extraction processes like HPAL (high-pressure acid leaching). Nickel sulfide deposits are preferred for battery-grade nickel production used in electric vehicle (EV) batteries and advanced alloys, benefiting from higher nickel purity and lower impurities. The growing EV market drives demand for sulfide-derived nickel in lithium-ion batteries, while laterite nickel remains dominant in traditional applications such as metal plating and coinage.

Future Prospects for Nickel Laterite and Sulfide Resources

Nickel laterite deposits are expected to play a crucial role in meeting future global demand due to their abundance and expanding processing technologies, especially in electric vehicle battery production. Nickel sulfide resources, while less abundant, offer higher-grade ore and more efficient extraction methods, making them valuable for long-term sustainable supply. Innovations in hydrometallurgical processes and increased investments in laterite nickel refining promise to enhance cost-effectiveness and reduce environmental impacts, driving the future growth of both resource types.

Nickel laterite vs nickel sulfide Infographic

materialdif.com

materialdif.com