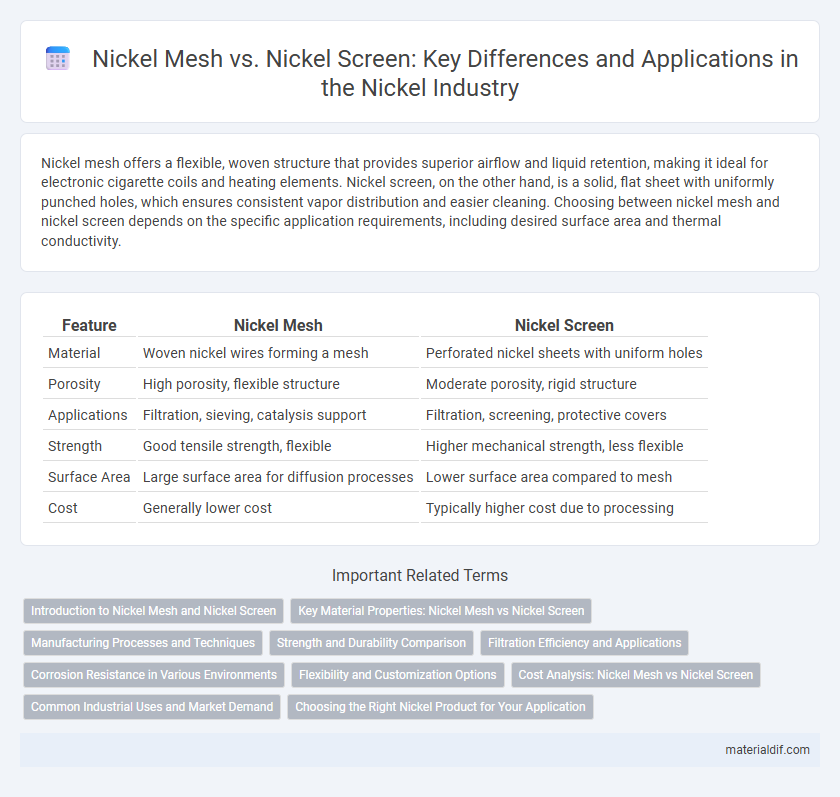

Nickel mesh offers a flexible, woven structure that provides superior airflow and liquid retention, making it ideal for electronic cigarette coils and heating elements. Nickel screen, on the other hand, is a solid, flat sheet with uniformly punched holes, which ensures consistent vapor distribution and easier cleaning. Choosing between nickel mesh and nickel screen depends on the specific application requirements, including desired surface area and thermal conductivity.

Table of Comparison

| Feature | Nickel Mesh | Nickel Screen |

|---|---|---|

| Material | Woven nickel wires forming a mesh | Perforated nickel sheets with uniform holes |

| Porosity | High porosity, flexible structure | Moderate porosity, rigid structure |

| Applications | Filtration, sieving, catalysis support | Filtration, screening, protective covers |

| Strength | Good tensile strength, flexible | Higher mechanical strength, less flexible |

| Surface Area | Large surface area for diffusion processes | Lower surface area compared to mesh |

| Cost | Generally lower cost | Typically higher cost due to processing |

Introduction to Nickel Mesh and Nickel Screen

Nickel mesh consists of woven wires forming a grid with uniform openings, providing excellent corrosion resistance and mechanical strength, ideal for filtration and shielding applications. Nickel screens, typically made by perforating or weaving wires into finer patterns, offer enhanced precision for sieving and electronic component protection. Both forms leverage nickel's durability and conductivity, but mesh tends to be coarser, while screens offer finer, more consistent filtration capabilities.

Key Material Properties: Nickel Mesh vs Nickel Screen

Nickel mesh features a woven structure with consistent pore size, offering excellent tensile strength and corrosion resistance ideal for filtration and catalyst support. Nickel screen, typically a woven or welded wire product, provides higher rigidity and durability but with less flexibility in pore uniformity. Both materials share high thermal conductivity and oxidation resistance, making them suitable for high-temperature industrial applications.

Manufacturing Processes and Techniques

Nickel mesh production involves weaving fine nickel wires into a grid pattern using precise weaving looms, ensuring uniform apertures and consistent tensile strength; this process emphasizes wire gauge selection and mesh count for tailored filtration or screening applications. Nickel screens, typically manufactured through expanded metal techniques, start with nickel sheets that are slit and stretched to create diamond-shaped openings, providing higher rigidity and strength compared to woven meshes. The choice between weaving for nickel mesh and expansion for nickel screens significantly impacts mechanical properties, durability, and suitability in harsh chemical or high-temperature environments.

Strength and Durability Comparison

Nickel mesh boasts superior strength due to its woven structure, providing enhanced resistance to deformation under high stress compared to nickel screens, which have a more rigid and less flexible framework. The durability of nickel mesh excels in corrosive and high-temperature environments, maintaining integrity and performance longer than nickel screens that may be prone to cracking or breaking under similar conditions. Overall, nickel mesh offers improved longevity and mechanical resilience, making it ideal for demanding industrial applications requiring robust material performance.

Filtration Efficiency and Applications

Nickel mesh offers higher filtration efficiency due to its uniform aperture size and superior mechanical strength, making it ideal for precision filtration in chemical processing and air purification systems. Nickel screens provide more versatility in pore size and are commonly used in less demanding filtration applications such as oil filtration and pharmaceutical sieving. Both materials excel in corrosion resistance and high-temperature performance, but nickel mesh is preferred where fine particle filtration and durability are critical.

Corrosion Resistance in Various Environments

Nickel mesh offers superior corrosion resistance in harsh chemical environments due to its woven structure, which allows for better flow and reduced accumulation of corrosive agents. Nickel screen, while effective, may have lower durability in acidic or alkaline conditions because its punched pattern can trap contaminants, accelerating corrosion. Both materials perform well against oxidation, but nickel mesh is preferred in industrial applications demanding long-term exposure to corrosive substances.

Flexibility and Customization Options

Nickel mesh offers superior flexibility compared to nickel screens, making it ideal for applications requiring material bending or shaping without compromising integrity. Customization options for nickel mesh include varied wire diameters and mesh sizes to meet specific filtration or protective needs, while nickel screens typically provide fixed sizes and limited adaptiveness. This versatility in nickel mesh ensures enhanced performance in complex or dynamic environments.

Cost Analysis: Nickel Mesh vs Nickel Screen

Nickel mesh typically offers a lower cost option compared to nickel screens due to its simpler manufacturing process and less material usage. The price difference is influenced by factors such as mesh size, wire diameter, and product thickness, with nickel screens often requiring more precise fabrication and finishing techniques that increase expenses. Cost analysis should also consider application requirements, as nickel screen's enhanced filtration efficiency may justify the higher price in specific industrial uses.

Common Industrial Uses and Market Demand

Nickel mesh and nickel screen are widely used in industrial filtration and separation processes, with nickel mesh favored for chemical filtration due to its high corrosion resistance and durability, while nickel screen is preferred in mining and food processing for particle sizing and screening. The market demand for nickel mesh is driven by its use in aerospace and chemical industries requiring precise filtration, whereas nickel screen sees significant demand in bulk material handling and agricultural sectors. Advancements in manufacturing technology and increasing industrial applications continue to boost the global demand for both nickel mesh and nickel screen.

Choosing the Right Nickel Product for Your Application

Nickel mesh offers a flexible and durable filtering solution with a uniform weave suitable for high-temperature and corrosive environments, making it ideal for chemical processing and filtration applications. Nickel screen provides precise control over aperture size and wire thickness, enhancing performance in electronic shielding and fine particulate separation. Selecting the right product depends on the application's specific requirements for strength, corrosion resistance, and filtration precision.

Nickel Mesh vs Nickel Screen Infographic

materialdif.com

materialdif.com