Duplex nickel coatings combine a base layer of electroplated nickel with an outer layer of electroless nickel, offering enhanced corrosion resistance and improved hardness compared to single layer nickel deposits. Single layer nickel provides a uniform protective barrier but may lack the durability and performance benefits found in duplex systems. Choosing duplex nickel results in longer-lasting protection for automotive, industrial, and decorative applications where superior wear and corrosion resistance are critical.

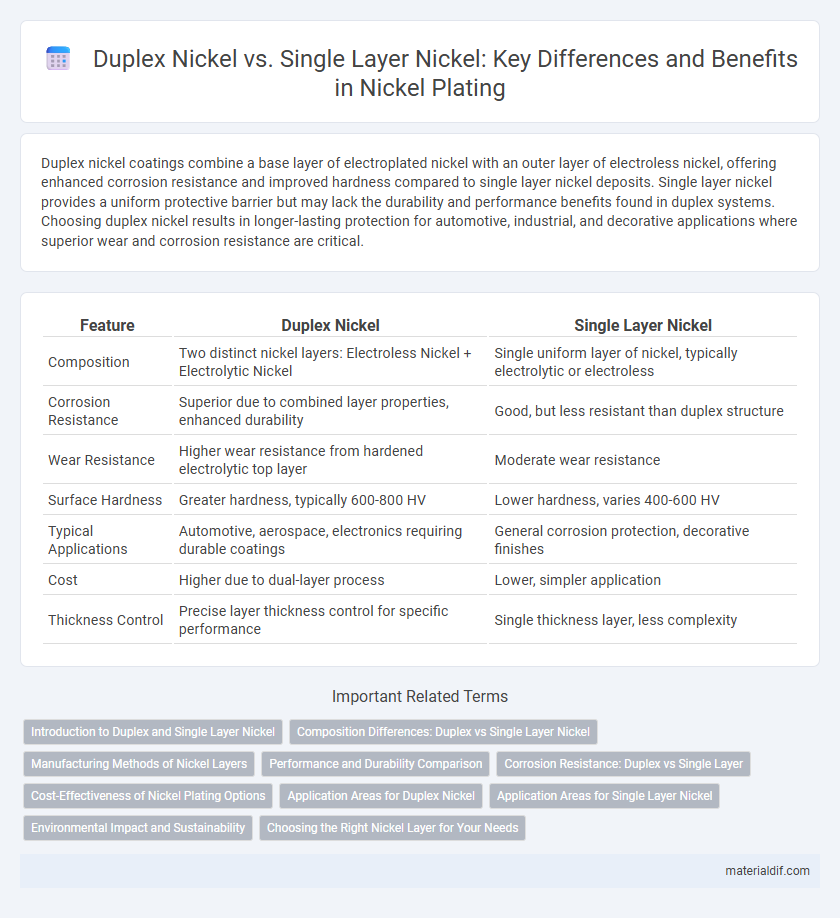

Table of Comparison

| Feature | Duplex Nickel | Single Layer Nickel |

|---|---|---|

| Composition | Two distinct nickel layers: Electroless Nickel + Electrolytic Nickel | Single uniform layer of nickel, typically electrolytic or electroless |

| Corrosion Resistance | Superior due to combined layer properties, enhanced durability | Good, but less resistant than duplex structure |

| Wear Resistance | Higher wear resistance from hardened electrolytic top layer | Moderate wear resistance |

| Surface Hardness | Greater hardness, typically 600-800 HV | Lower hardness, varies 400-600 HV |

| Typical Applications | Automotive, aerospace, electronics requiring durable coatings | General corrosion protection, decorative finishes |

| Cost | Higher due to dual-layer process | Lower, simpler application |

| Thickness Control | Precise layer thickness control for specific performance | Single thickness layer, less complexity |

Introduction to Duplex and Single Layer Nickel

Duplex nickel plating consists of two distinct layers: a dense, corrosion-resistant base layer topped with a fine-grain, wear-resistant outer layer, optimizing both durability and protection. Single layer nickel plating provides a uniform coating with moderate corrosion resistance and hardness, suitable for general applications with less demanding conditions. The duplex system enhances performance by combining properties of both layers, offering superior longevity compared to single-layer nickel coatings.

Composition Differences: Duplex vs Single Layer Nickel

Duplex nickel coatings consist of two distinct layers, typically a strike layer of pure nickel followed by a thicker layer of electroless or electroplated nickel-phosphorus or nickel-boron alloy, enhancing corrosion resistance and hardness. Single layer nickel coatings usually comprise a uniform layer of pure nickel or a nickel alloy such as nickel-phosphorus, providing good ductility and moderate corrosion protection. The primary compositional difference lies in the duplex system's multi-layer approach combining pure nickel and alloyed nickel, whereas single layer coatings rely on homogeneous composition for performance.

Manufacturing Methods of Nickel Layers

Duplex nickel coatings combine an electroplated bright nickel base layer with a subsequent electroless nickel-phosphorus top layer, enhancing corrosion resistance and hardness compared to single layer nickel which is typically deposited solely by electroplating. Manufacturing duplex nickel involves a two-step process where the initial electroplated layer ensures strong adhesion followed by an autocatalytic electroless layer providing uniform coverage and improved wear properties. Single layer nickel coatings rely on one homogeneous electroplating bath, making the process simpler but less effective in delivering multifunctional surface characteristics.

Performance and Durability Comparison

Duplex nickel coatings exhibit superior performance and durability compared to single-layer nickel due to their enhanced corrosion resistance and wear protection, achieved by combining a dense barrier layer with a ductile outer layer. The dual-layer structure reduces the risk of cracking and peeling under mechanical stress, extending the lifespan of coated components in harsh environments. Single-layer nickel offers moderate protection but typically falls short in applications requiring high resistance to abrasion and chemical attack.

Corrosion Resistance: Duplex vs Single Layer

Duplex nickel coatings offer superior corrosion resistance compared to single layer nickel due to their multi-layered structure, which provides enhanced barrier properties against environmental factors. The dual layers create a more effective defense against oxidation and chemical attack, significantly prolonging the lifespan of coated materials. Single layer nickel tends to be more vulnerable to pitting and surface degradation under harsh conditions, making duplex coatings the preferred choice for high-corrosion environments.

Cost-Effectiveness of Nickel Plating Options

Duplex nickel plating offers enhanced corrosion resistance and durability compared to single layer nickel, making it a cost-effective choice for long-term applications despite a higher initial cost. Single layer nickel plating provides basic protection at a lower upfront price, but may require more frequent maintenance and recoating due to lower wear resistance. Evaluating the total lifecycle cost, duplex nickel plating often results in lower overall expenses by reducing downtime and replacement frequency.

Application Areas for Duplex Nickel

Duplex nickel coatings are widely used in demanding industrial applications requiring enhanced corrosion resistance, such as automotive components, aerospace parts, and chemical processing equipment. Their dual-layer structure combines a dense nickel undercoat with a hard, protective top layer to improve wear resistance and extend service life in harsh environments. Single layer nickel coatings are typically applied in less aggressive settings like decorative finishes or moderate corrosion protection, where durability requirements are lower.

Application Areas for Single Layer Nickel

Single Layer Nickel coatings are widely used in the electronics industry for printed circuit boards due to their excellent conductivity and solderability. They also serve crucial roles in automotive parts, providing corrosion resistance and wear protection on components like fuel systems and engine parts. Furthermore, Single Layer Nickel is preferred in decorative applications where a smooth, uniform finish is required without the complexity of multilayer processes.

Environmental Impact and Sustainability

Duplex nickel coatings offer enhanced corrosion resistance and durability compared to single layer nickel, reducing the frequency of reapplications and thereby lowering environmental waste. The multi-layer structure in duplex nickel minimizes the leaching of harmful nickel ions into soil and water, supporting better ecological sustainability. Single layer nickel, while easier to apply, tends to degrade faster, potentially increasing toxic runoff and resource consumption over time.

Choosing the Right Nickel Layer for Your Needs

Duplex nickel coatings combine an electroless nickel layer with an additional electroplated nickel layer, enhancing corrosion resistance and hardness compared to single layer nickel. Choosing duplex nickel is ideal for applications requiring superior wear resistance, uniform coverage in complex geometries, and extended durability in harsh environments. Single layer nickel suits simpler applications where cost-efficiency and moderate protection against corrosion and abrasion are sufficient.

Duplex Nickel vs Single Layer Nickel Infographic

materialdif.com

materialdif.com