Nickel-coated steel offers superior corrosion resistance and a smoother, more aesthetically pleasing finish compared to galvanized steel, making it ideal for applications requiring durability and appearance. Galvanized steel, coated with a layer of zinc, provides cost-effective protection against rust but may wear down faster in harsher environments. Choosing between nickel-coated and galvanized steel depends on the specific needs for longevity, environmental exposure, and budget constraints.

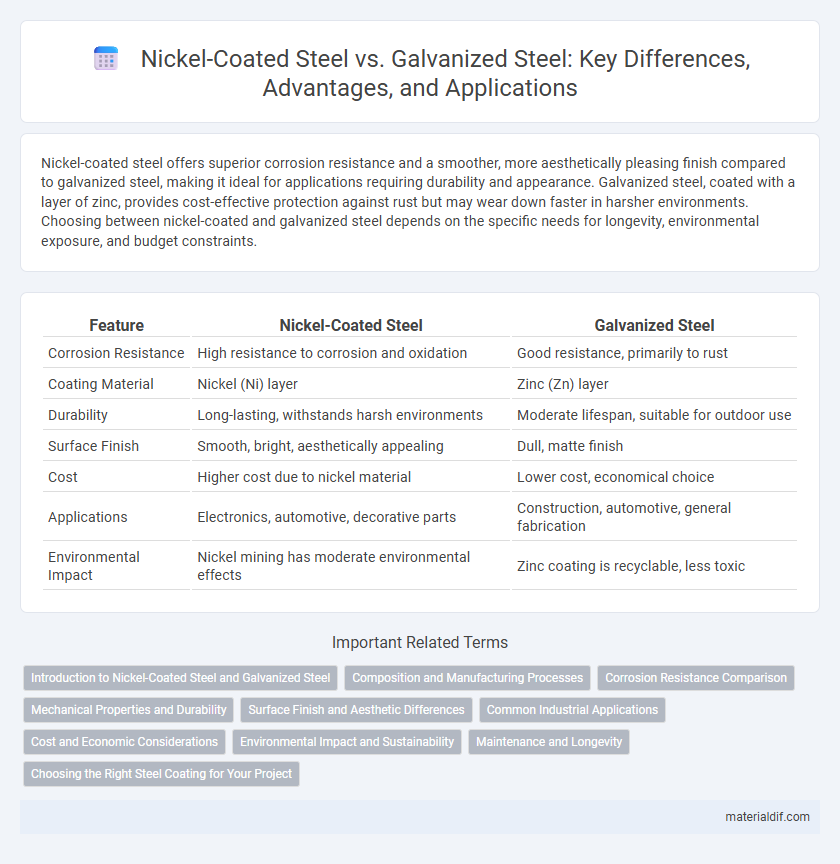

Table of Comparison

| Feature | Nickel-Coated Steel | Galvanized Steel |

|---|---|---|

| Corrosion Resistance | High resistance to corrosion and oxidation | Good resistance, primarily to rust |

| Coating Material | Nickel (Ni) layer | Zinc (Zn) layer |

| Durability | Long-lasting, withstands harsh environments | Moderate lifespan, suitable for outdoor use |

| Surface Finish | Smooth, bright, aesthetically appealing | Dull, matte finish |

| Cost | Higher cost due to nickel material | Lower cost, economical choice |

| Applications | Electronics, automotive, decorative parts | Construction, automotive, general fabrication |

| Environmental Impact | Nickel mining has moderate environmental effects | Zinc coating is recyclable, less toxic |

Introduction to Nickel-Coated Steel and Galvanized Steel

Nickel-coated steel features a thin layer of nickel deposited on the steel surface, providing enhanced corrosion resistance, wear resistance, and a bright, attractive finish ideal for decorative and industrial applications. Galvanized steel involves coating steel with a layer of zinc, primarily to protect against rust and corrosion, making it widely used in construction, automotive, and outdoor environments. Both coatings extend the lifespan of steel, with nickel coatings offering superior durability and aesthetic qualities, while galvanized coatings are cost-effective and efficient for large-scale protective needs.

Composition and Manufacturing Processes

Nickel-coated steel features a thin layer of nickel applied through electroplating, enhancing corrosion resistance and providing a smooth, aesthetically appealing surface. Galvanized steel undergoes a hot-dip or electro-galvanizing process where zinc is coated onto the steel substrate, offering robust protection against rust and environmental damage. The distinct compositions--nickel's hardness and zinc's sacrificial properties--dictate their manufacturing processes and performance in applications requiring durability and corrosion resistance.

Corrosion Resistance Comparison

Nickel-coated steel exhibits superior corrosion resistance compared to galvanized steel due to its dense, uniform nickel layer that effectively protects against oxidation and chemical exposure. While galvanized steel relies on a zinc coating that sacrifices itself to prevent rust, the nickel coating offers enhanced durability in harsh environments, including resistance to acids and alkaline substances. This makes nickel-coated steel ideal for applications requiring long-lasting protection in marine, chemical, and industrial settings.

Mechanical Properties and Durability

Nickel-coated steel exhibits superior mechanical properties such as increased hardness and tensile strength compared to galvanized steel, making it ideal for applications requiring enhanced wear and corrosion resistance. The nickel coating provides a dense, uniform barrier that significantly improves durability by resisting oxidation and chemical degradation better than the traditional zinc coating found in galvanized steel. This enhanced protection extends the lifespan of steel components in harsh environments, particularly where exposure to moisture, salt, or acidic conditions is prevalent.

Surface Finish and Aesthetic Differences

Nickel-coated steel presents a smooth, shiny, and corrosion-resistant surface with a bright, silver-white finish ideal for decorative and high-wear applications. Galvanized steel features a matte to slightly rough zinc coating that offers robust protection against rust but has a duller, less reflective appearance. The superior luster and durability of nickel coatings make them preferred for aesthetic-focused projects, while galvanized steel is often chosen for functional, industrial uses where appearance is secondary.

Common Industrial Applications

Nickel-coated steel offers superior corrosion resistance and enhanced surface hardness, making it ideal for applications in automotive parts, electronics, and chemical processing equipment. Galvanized steel is widely used in construction, outdoor structures, and HVAC systems due to its cost-effective zinc coating that protects against rust. Both materials are favored in industries requiring durable metal solutions, with nickel-coated steel preferred for high-wear environments and galvanized steel for economical, large-scale projects.

Cost and Economic Considerations

Nickel-coated steel typically incurs higher costs compared to galvanized steel due to the expensive raw material and complex coating process involved. Galvanized steel offers a more economical option with durable corrosion resistance provided by zinc coating, making it suitable for large-scale construction and industrial applications. Cost-effectiveness and maintenance expenses often favor galvanized steel, especially in budget-sensitive projects requiring long-term protection.

Environmental Impact and Sustainability

Nickel-coated steel offers superior corrosion resistance, reducing the frequency of replacements and minimizing waste, thereby supporting sustainability efforts. Galvanized steel, coated primarily with zinc, is more prone to environmental contamination during the manufacturing process due to zinc runoff. In terms of recyclability, both materials are recyclable, but nickel-coated steel's longer lifespan and durability generally result in a lower environmental impact over the product lifecycle.

Maintenance and Longevity

Nickel-coated steel offers superior corrosion resistance compared to galvanized steel, significantly reducing maintenance frequency and costs in harsh environments. Its dense, durable nickel layer provides long-lasting protection against rust, extending the steel's service life beyond that of typical zinc coatings. Galvanized steel requires more regular inspections and potential reapplication of coatings to maintain integrity, especially in acidic or marine conditions.

Choosing the Right Steel Coating for Your Project

Nickel-coated steel offers superior corrosion resistance and enhanced durability compared to galvanized steel, making it ideal for projects exposed to harsh environments or requiring a polished finish. Galvanized steel, coated with zinc, provides cost-effective protection against rust and is suitable for general construction and outdoor applications. Selecting the right steel coating depends on factors like environmental conditions, budget constraints, and the desired aesthetic appeal for the project.

Nickel-Coated Steel vs Galvanized Steel Infographic

materialdif.com

materialdif.com