Nickel coating involves applying a thin layer of nickel onto a substrate to enhance corrosion resistance and improve surface hardness, commonly used in industrial applications requiring durable finishes. Nickel cladding, on the other hand, refers to bonding a thicker layer of nickel alloy to a base metal, providing superior wear resistance and extended protection in harsh environments. Choosing between nickel coating and cladding depends on the required thickness, durability, and specific performance needs of the nickel-pet products.

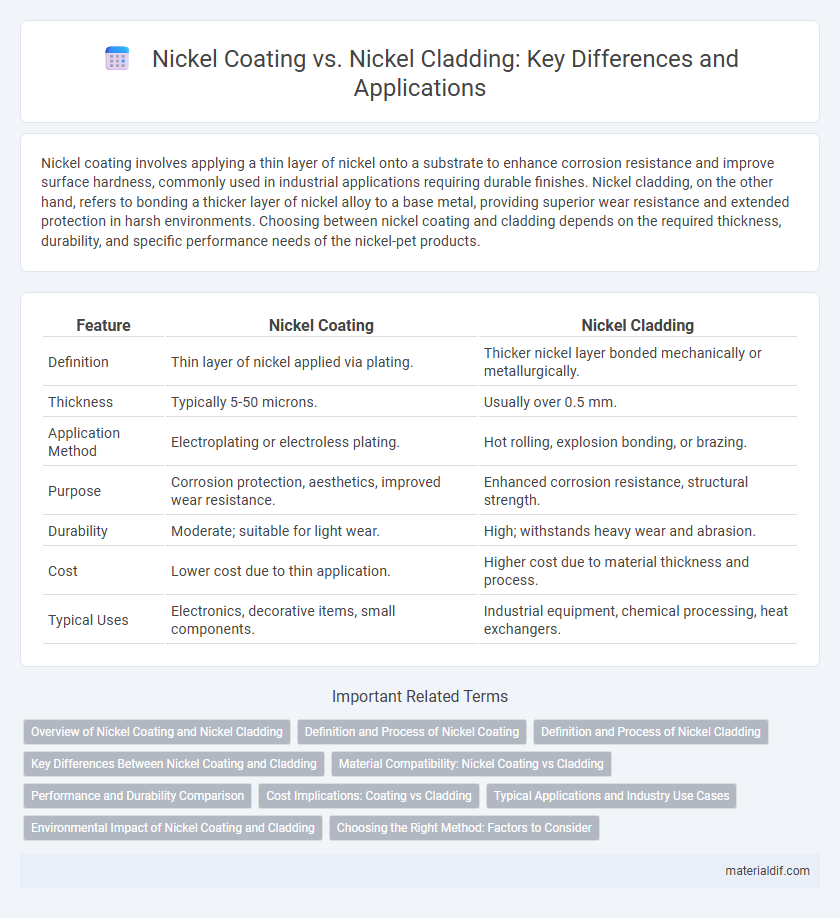

Table of Comparison

| Feature | Nickel Coating | Nickel Cladding |

|---|---|---|

| Definition | Thin layer of nickel applied via plating. | Thicker nickel layer bonded mechanically or metallurgically. |

| Thickness | Typically 5-50 microns. | Usually over 0.5 mm. |

| Application Method | Electroplating or electroless plating. | Hot rolling, explosion bonding, or brazing. |

| Purpose | Corrosion protection, aesthetics, improved wear resistance. | Enhanced corrosion resistance, structural strength. |

| Durability | Moderate; suitable for light wear. | High; withstands heavy wear and abrasion. |

| Cost | Lower cost due to thin application. | Higher cost due to material thickness and process. |

| Typical Uses | Electronics, decorative items, small components. | Industrial equipment, chemical processing, heat exchangers. |

Overview of Nickel Coating and Nickel Cladding

Nickel coating involves applying a thin layer of nickel onto a substrate to enhance corrosion resistance, wear protection, and aesthetic appeal, typically through electroplating or electroless plating methods. Nickel cladding refers to the process of bonding a thicker nickel layer onto a base metal, providing superior durability and corrosion resistance in harsh environments, often used in marine and chemical industries. Both techniques improve surface properties but differ primarily in layer thickness, adhesion strength, and application scope.

Definition and Process of Nickel Coating

Nickel coating involves depositing a thin layer of nickel onto a substrate using electroplating or electroless plating to enhance corrosion resistance, wear resistance, and aesthetic appeal. The process begins with surface preparation, including cleaning and activating the base material, followed by immersion in a nickel salt solution where nickel ions are reduced and adhered to the surface. Unlike nickel cladding, which refers to bonding a nickel sheet onto a material, nickel coating produces a uniform, controlled thickness layer ideal for precise protective and decorative applications.

Definition and Process of Nickel Cladding

Nickel cladding involves bonding a thick layer of nickel onto a substrate material through processes such as welding, explosive bonding, or roll bonding, creating a metallurgical bond for enhanced corrosion resistance and durability. Unlike nickel coating, which deposits a thin layer of nickel via electroplating or electroless plating, cladding provides a robust, wear-resistant surface ideal for heavy-duty industrial applications. The cladding process ensures a seamless, defect-free bond, significantly improving the mechanical properties and lifespan of the underlying material.

Key Differences Between Nickel Coating and Cladding

Nickel coating involves electroplating a thin layer of nickel onto the surface of a substrate, providing corrosion resistance, enhanced wear protection, and improved appearance without significantly altering the part's thickness or dimensions. In contrast, nickel cladding typically refers to a thicker, metallurgically bonded nickel layer applied through processes such as hot rolling or welding, resulting in a robust, integral layer that enhances mechanical strength and durability of the base material. The key differences lie in coating's thin, surface-level protection versus cladding's substantial, structural nickel layer affecting component performance and lifespan.

Material Compatibility: Nickel Coating vs Cladding

Nickel coating involves applying a thin layer of pure nickel onto a substrate through electroplating or electroless plating, providing corrosion resistance and wear protection primarily on metals compatible with nickel bonding. Nickel cladding, however, is a metallurgical process where a thicker nickel alloy layer is metallurgically bonded to the base metal under heat and pressure, ensuring enhanced durability and compatibility with substrates like stainless steel and carbon steel. Material compatibility for nickel coating depends on surface preparation and electrochemical properties, while nickel cladding offers superior bonding strength and is better suited for applications requiring heavy-duty protection and integrity under mechanical stress.

Performance and Durability Comparison

Nickel coating provides a thin, uniform layer that enhances corrosion resistance and surface hardness, making it ideal for precision components requiring wear protection. Nickel cladding involves bonding a thicker nickel layer to a substrate, offering superior durability and resistance to mechanical damage under harsh environmental conditions. Performance-wise, nickel cladding outperforms nickel coating in longevity and impact resistance, while nickel coating excels in fine detail preservation and cost-efficiency.

Cost Implications: Coating vs Cladding

Nickel coating generally offers a lower upfront cost compared to nickel cladding, making it a cost-effective solution for applications requiring corrosion resistance and surface enhancement. Nickel cladding involves a thicker, more durable layer often bonded through advanced metallurgical processes, leading to higher material and labor expenses. Long-term maintenance costs may be reduced with nickel cladding due to its superior wear resistance and structural integrity.

Typical Applications and Industry Use Cases

Nickel coating is widely used in automotive and aerospace industries for wear resistance and corrosion protection on engine parts and turbine blades. Nickel cladding, often employed in chemical processing and electronics, provides a thicker, metallurgically bonded barrier ideal for harsh environments and electrical conductivity enhancement. Both methods serve critical roles in manufacturing, with nickel coating favoring surface treatments and nickel cladding ensuring structural durability and extended lifespan.

Environmental Impact of Nickel Coating and Cladding

Nickel coating and nickel cladding differ significantly in their environmental impact due to the processes involved. Nickel coating typically involves electroplating, which can generate hazardous waste and requires careful management of toxic chemicals like nickel salts and cyanides to prevent soil and water contamination. In contrast, nickel cladding is often applied through mechanical or metallurgical methods that generally produce less harmful waste, resulting in a lower environmental footprint during manufacturing.

Choosing the Right Method: Factors to Consider

Nickel coating provides a thin, protective layer primarily through electroplating, enhancing corrosion resistance and surface hardness, making it ideal for delicate components. Nickel cladding involves bonding a thicker nickel layer to a substrate, offering superior wear resistance and structural support for heavy-duty applications. Key factors to consider when choosing between them include the required durability, environmental exposure, cost constraints, and the component's mechanical stress tolerance.

Nickel Coating vs Nickel Cladding Infographic

materialdif.com

materialdif.com