Monel offers excellent resistance to seawater and hydrofluoric acid, making it ideal for marine and chemical environments, while Hastelloy excels in withstanding extreme corrosion from oxidizing and reducing agents at high temperatures. Monel's strength and good thermal conductivity suit applications requiring durability and heat dissipation, whereas Hastelloy provides superior performance in highly aggressive environments such as chemical processing plants. Choosing between Monel and Hastelloy depends on the specific corrosion resistance, temperature tolerance, and mechanical properties needed for the application.

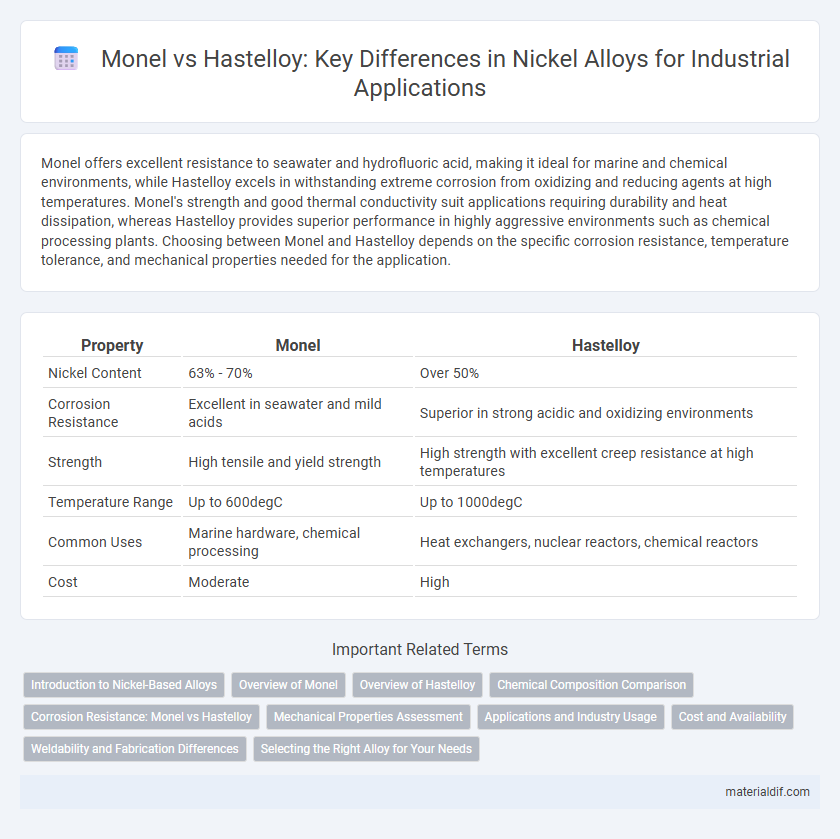

Table of Comparison

| Property | Monel | Hastelloy |

|---|---|---|

| Nickel Content | 63% - 70% | Over 50% |

| Corrosion Resistance | Excellent in seawater and mild acids | Superior in strong acidic and oxidizing environments |

| Strength | High tensile and yield strength | High strength with excellent creep resistance at high temperatures |

| Temperature Range | Up to 600degC | Up to 1000degC |

| Common Uses | Marine hardware, chemical processing | Heat exchangers, nuclear reactors, chemical reactors |

| Cost | Moderate | High |

Introduction to Nickel-Based Alloys

Nickel-based alloys, including Monel and Hastelloy, are renowned for their exceptional corrosion resistance, high strength, and excellent performance in extreme environments. Monel, primarily composed of nickel and copper, offers superior resistance to seawater and hydrocarbon environments, making it ideal for marine applications and chemical processing. Hastelloy, containing a higher proportion of molybdenum and chromium, excels in highly corrosive chemical processing industries, especially where acids and oxidizing agents are prevalent.

Overview of Monel

Monel is a nickel-copper alloy known for its exceptional corrosion resistance and strength, particularly in marine and chemical environments. It contains approximately 65-70% nickel with significant amounts of copper, iron, manganese, and other trace elements, which enhance its durability and resistance to acid and alkaline settings. Monel is extensively utilized in pumps, valves, and marine engineering applications due to its ability to withstand corrosive saltwater and high-pressure conditions.

Overview of Hastelloy

Hastelloy is a corrosion-resistant metal alloy primarily composed of nickel, with significant amounts of molybdenum and chromium enhancing its strength and chemical stability. It excels in harsh environments, particularly in handling strong oxidizers and highly acidic conditions, making it ideal for chemical processing industries. Compared to Monel, Hastelloy offers superior resistance to pitting, crevice corrosion, and stress corrosion cracking.

Chemical Composition Comparison

Monel primarily consists of nickel (up to 67%) and copper (up to 30%), with small amounts of iron, manganese, and silicon, offering excellent corrosion resistance in marine environments. Hastelloy is a nickel-based alloy containing significant amounts of molybdenum (up to 16%), chromium (up to 22%), and iron, providing superior resistance to high-temperature oxidation and aggressive chemical environments. The varying chemical composition between Monel and Hastelloy dictates their applications, with Monel favored for marine and acidic settings, while Hastelloy excels in chemical processing and high-temperature industries.

Corrosion Resistance: Monel vs Hastelloy

Monel alloys, primarily composed of nickel and copper, exhibit excellent corrosion resistance in marine and acidic environments, particularly against seawater and hydrofluoric acid. Hastelloy, a nickel-molybdenum-chromium alloy, offers superior resistance to oxidizing and reducing chemicals, including strong acids like hydrochloric and sulfuric acid under higher temperatures. Hastelloy outperforms Monel in highly aggressive chemical environments due to its enhanced molybdenum content, making it ideal for chemical processing and aerospace applications.

Mechanical Properties Assessment

Monel alloys exhibit high tensile strength and excellent corrosion resistance, particularly in marine and chemical environments, with yield strengths typically ranging from 300 to 700 MPa. Hastelloy, a nickel-based superalloy, offers superior mechanical properties at elevated temperatures, including enhanced creep resistance and strength above 800 MPa, making it ideal for high-stress applications such as chemical reactors and aerospace components. The mechanical performance of Monel is generally optimized for moderate temperature applications, while Hastelloy provides exceptional durability under extreme thermal and corrosive conditions.

Applications and Industry Usage

Monel, a nickel-copper alloy, is extensively used in marine engineering, chemical processing, and aerospace due to its excellent corrosion resistance in seawater and acidic environments. Hastelloy, primarily composed of nickel with molybdenum and iron, is favored in chemical reactors, nuclear reactors, and heat exchangers for its superior resistance to oxidizing and reducing agents at high temperatures. Both alloys are critical in industries requiring durable materials, with Monel preferred for marine applications and Hastelloy dominating in high-temperature chemical processing.

Cost and Availability

Monel typically offers a lower cost and greater availability compared to Hastelloy, making it a more budget-friendly option for many industrial applications. Hastelloy, known for its superior corrosion resistance and high-performance properties, generally commands a higher price and can be less readily available due to its complex alloy composition. Industrial buyers prioritize Monel when cost-effectiveness and widespread supply are critical, while Hastelloy is chosen for specialized environments despite its premium cost and limited availability.

Weldability and Fabrication Differences

Monel, primarily composed of nickel and copper, offers excellent weldability with minimal post-weld treatment due to its resistance to cracking and distortion. Hastelloy, a nickel-molybdenum alloy, requires specialized welding techniques such as TIG or MIG with controlled heat input to prevent sensitization and maintain corrosion resistance. Fabrication of Monel is generally easier and more cost-effective, whereas Hastelloy demands precise handling and post-weld heat treatment to preserve its mechanical and chemical properties.

Selecting the Right Alloy for Your Needs

Monel offers exceptional corrosion resistance in marine and acidic environments, making it ideal for plumbing and chemical processing applications. Hastelloy excels in high-temperature and highly corrosive conditions, especially in chemical reactors and heat exchangers. Selecting the right alloy depends on factors like exposure to specific chemicals, operating temperatures, and mechanical stress requirements.

Monel vs Hastelloy Infographic

materialdif.com

materialdif.com