Nickel pet products offer excellent corrosion resistance and a smooth finish that enhances durability and hygiene. Stainless steel provides superior strength and rust resistance, making it ideal for heavy-duty pet accessories. Choosing between nickel and stainless steel depends on the balance between aesthetic appeal and long-term durability required for pet care items.

Table of Comparison

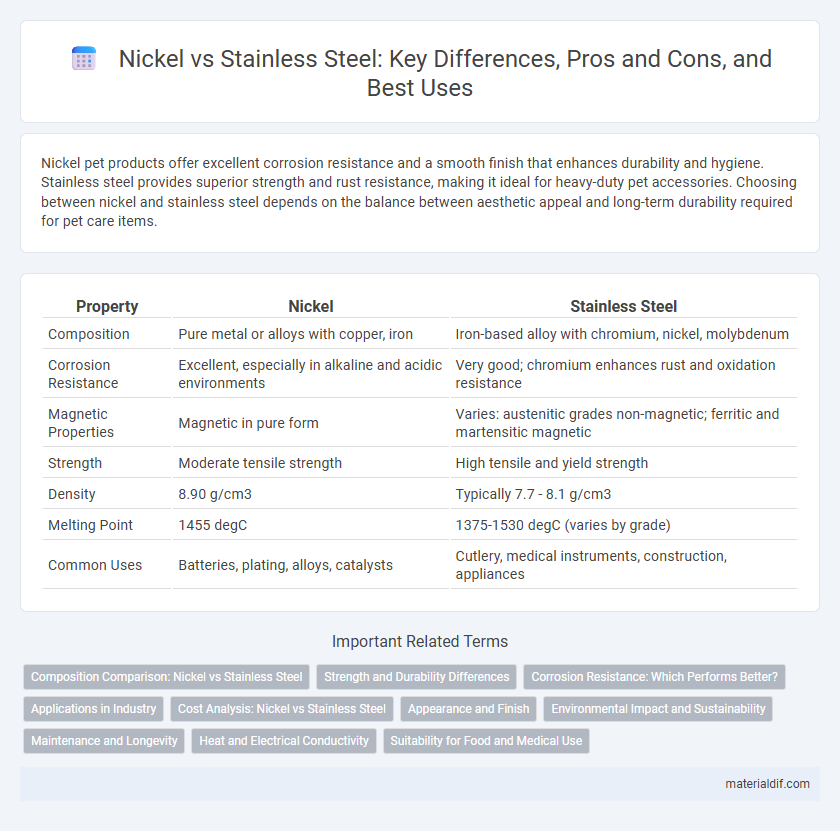

| Property | Nickel | Stainless Steel |

|---|---|---|

| Composition | Pure metal or alloys with copper, iron | Iron-based alloy with chromium, nickel, molybdenum |

| Corrosion Resistance | Excellent, especially in alkaline and acidic environments | Very good; chromium enhances rust and oxidation resistance |

| Magnetic Properties | Magnetic in pure form | Varies: austenitic grades non-magnetic; ferritic and martensitic magnetic |

| Strength | Moderate tensile strength | High tensile and yield strength |

| Density | 8.90 g/cm3 | Typically 7.7 - 8.1 g/cm3 |

| Melting Point | 1455 degC | 1375-1530 degC (varies by grade) |

| Common Uses | Batteries, plating, alloys, catalysts | Cutlery, medical instruments, construction, appliances |

Composition Comparison: Nickel vs Stainless Steel

Nickel is a pure metal known for its high corrosion resistance and excellent ductility, primarily composed of elemental nickel with trace impurities. Stainless steel is an alloy composed mainly of iron, chromium (typically 10.5% to 30%), and varying amounts of nickel, which enhances its corrosion resistance, strength, and luster. The presence of chromium and nickel within stainless steel alloys differentiates its composition significantly from pure nickel, contributing to greater hardness and diverse industrial applications.

Strength and Durability Differences

Nickel enhances the strength and corrosion resistance of stainless steel, making it more durable in harsh environments. Pure nickel offers high tensile strength and excellent resistance to oxidation, but stainless steel alloys containing nickel combine this with superior hardness and structural integrity. Stainless steel generally outperforms pure nickel in wear resistance and mechanical durability, especially in applications requiring toughness and long-term stability.

Corrosion Resistance: Which Performs Better?

Nickel exhibits superior corrosion resistance in harsh environments, particularly against acids and alkalis, outperforming many stainless steel grades. Stainless steel contains varying nickel content, which enhances its corrosion resistance, yet its performance depends heavily on the specific alloy composition and environmental conditions. In marine or highly corrosive atmospheres, high-nickel alloys or pure nickel generally provide better longevity and resistance compared to conventional stainless steel.

Applications in Industry

Nickel is widely used in industrial applications requiring high corrosion resistance and heat tolerance, such as chemical processing plants and aerospace components, due to its superior oxidation resistance. Stainless steel, an alloy containing significant nickel content, combines the strength of steel with nickel's corrosion resistance, making it ideal for construction, automotive, and food processing industries. The choice between pure nickel and stainless steel depends on specific performance requirements like tensile strength, machinability, and environmental exposure.

Cost Analysis: Nickel vs Stainless Steel

Nickel generally incurs higher raw material and production costs compared to stainless steel due to its scarcity and complex extraction processes. Stainless steel offers a cost-effective alternative, combining durability with lower manufacturing expenses and widespread availability. Long-term maintenance and corrosion resistance also impact overall cost efficiency, with stainless steel often providing better value in large-scale or budget-sensitive projects.

Appearance and Finish

Nickel offers a bright, reflective finish that enhances corrosion resistance and maintains its luster over time, making it ideal for decorative applications. Stainless steel exhibits a more muted, matte to semi-gloss finish, valued for its durability and scratch resistance. While nickel plating can improve the aesthetic appeal of stainless steel surfaces, stainless steel itself provides a robust, low-maintenance finish suitable for industrial and architectural uses.

Environmental Impact and Sustainability

Nickel plays a crucial role in stainless steel production, enhancing corrosion resistance and durability, which extends product lifespan and reduces waste. However, nickel mining and refining have significant environmental impacts, including habitat disruption and high energy consumption, compared to the relatively lower ecological footprint of recycling stainless steel. Sustainable practices emphasize increasing stainless steel recycling rates and sourcing nickel from environmentally responsible mines to minimize overall environmental damage.

Maintenance and Longevity

Nickel offers superior corrosion resistance, enhancing the longevity of stainless steel alloys by preventing rust and degradation in harsh environments. Stainless steel containing higher nickel content requires less frequent maintenance due to its enhanced durability and resistance to oxidation. Over time, nickel-enriched stainless steel maintains structural integrity and aesthetic appeal, reducing replacement and repair costs.

Heat and Electrical Conductivity

Nickel exhibits superior heat resistance compared to many stainless steel grades, maintaining strength and corrosion resistance at elevated temperatures above 600degC. Although stainless steel, particularly austenitic types, offers moderate electrical conductivity, pure nickel has higher electrical conductivity, approximately 14.3 million siemens per meter (MS/m), compared to stainless steel's typical range of 1.4 to 1.8 MS/m. These properties make nickel a preferred choice in high-temperature and electrical applications where efficient heat dissipation and conductivity are critical.

Suitability for Food and Medical Use

Nickel offers excellent corrosion resistance and hypoallergenic properties, making it highly suitable for food processing equipment and medical instruments that demand sterility and durability. Stainless steel, enriched with nickel content, combines strength with enhanced resistance against oxidation and chemical exposure, widely used in surgical tools and kitchenware. Both materials meet stringent hygiene standards but stainless steel's alloy composition provides superior mechanical performance in demanding food and medical environments.

Nickel vs Stainless Steel Infographic

materialdif.com

materialdif.com