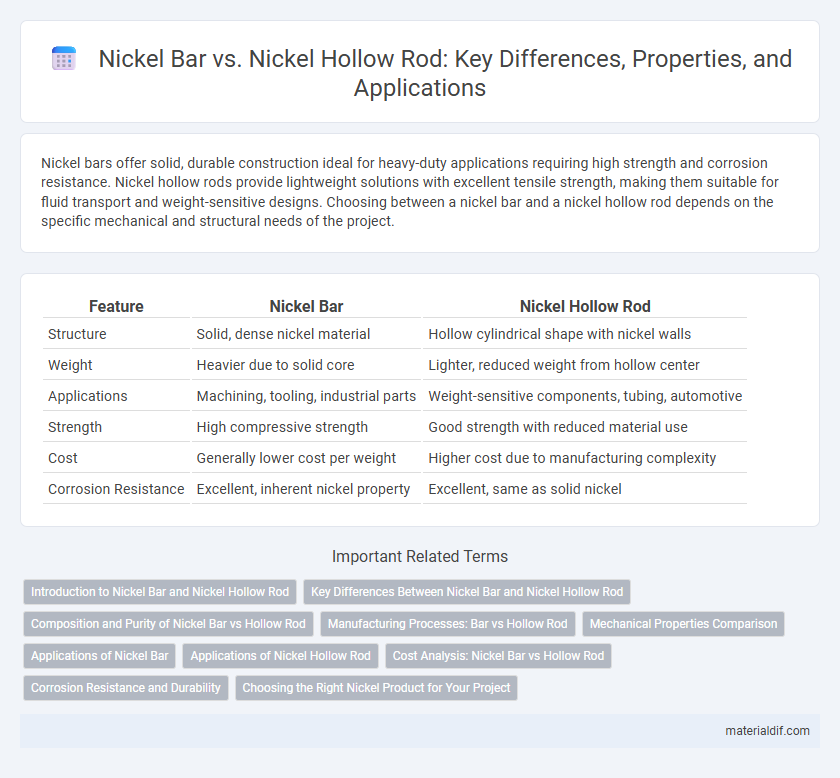

Nickel bars offer solid, durable construction ideal for heavy-duty applications requiring high strength and corrosion resistance. Nickel hollow rods provide lightweight solutions with excellent tensile strength, making them suitable for fluid transport and weight-sensitive designs. Choosing between a nickel bar and a nickel hollow rod depends on the specific mechanical and structural needs of the project.

Table of Comparison

| Feature | Nickel Bar | Nickel Hollow Rod |

|---|---|---|

| Structure | Solid, dense nickel material | Hollow cylindrical shape with nickel walls |

| Weight | Heavier due to solid core | Lighter, reduced weight from hollow center |

| Applications | Machining, tooling, industrial parts | Weight-sensitive components, tubing, automotive |

| Strength | High compressive strength | Good strength with reduced material use |

| Cost | Generally lower cost per weight | Higher cost due to manufacturing complexity |

| Corrosion Resistance | Excellent, inherent nickel property | Excellent, same as solid nickel |

Introduction to Nickel Bar and Nickel Hollow Rod

Nickel bars are solid metal rods widely used in manufacturing for their high corrosion resistance and excellent strength at elevated temperatures. Nickel hollow rods feature a cylindrical shape with a hollow center, reducing weight while maintaining mechanical integrity for applications requiring lighter components. Both forms are essential in aerospace, chemical processing, and marine industries, where nickel's durability and resistance to harsh environments are critical.

Key Differences Between Nickel Bar and Nickel Hollow Rod

Nickel bars are solid cylindrical rods commonly used in manufacturing for their strength and resistance to corrosion, making them suitable for heavy-duty applications. Nickel hollow rods, on the other hand, have a tubular structure that reduces weight while maintaining structural integrity, ideal for applications requiring lighter components without compromising durability. Key differences include the solid versus hollow cross-section, weight reduction in hollow rods, and specific use cases where hollow rods offer benefits in material savings and thermal conductivity.

Composition and Purity of Nickel Bar vs Hollow Rod

Nickel bars typically exhibit a higher purity level, often exceeding 99.8% nickel content, which makes them ideal for applications requiring exceptional corrosion resistance and strength. Nickel hollow rods, while also composed predominantly of high-purity nickel, may have slight variations in alloy composition to enhance flexibility and reduce weight for specialized engineering uses. The choice between nickel bars and hollow rods depends on the need for pure, solid material versus a lightweight, hollow structure with tailored mechanical properties.

Manufacturing Processes: Bar vs Hollow Rod

Nickel bars are typically manufactured through hot rolling or extrusion, producing a solid cylindrical shape with high structural integrity suitable for heavy-duty applications. Nickel hollow rods are made using extrusion or drawing processes with a mandrel to create a hollow center, optimizing material usage while maintaining strength and reducing weight. The choice between bar and hollow rod manufacturing depends on the required application, mechanical properties, and material efficiency.

Mechanical Properties Comparison

Nickel bars exhibit higher tensile strength and better machinability compared to nickel hollow rods, making them suitable for heavy-duty applications. Nickel hollow rods offer enhanced weight reduction and improved corrosion resistance due to their hollow structure, without significantly compromising mechanical integrity. Both forms provide excellent ductility and toughness, but selection depends on the required balance between structural strength and weight efficiency.

Applications of Nickel Bar

Nickel bars are widely used in manufacturing industries requiring excellent corrosion resistance and high strength, such as aerospace, chemical processing, and marine engineering. Their solid structure makes them ideal for machining into specialized components like shafts, bolts, and fittings that endure extreme environmental conditions. Unlike hollow rods, nickel bars provide superior durability and stability for structural applications where strength and reliability are critical.

Applications of Nickel Hollow Rod

Nickel hollow rods excel in applications requiring precise fluid flow control and structural support in chemical processing, aerospace, and medical devices due to their corrosion resistance and lightweight properties. Unlike solid nickel bars, hollow rods enable efficient heat transfer and reduce material costs while maintaining strength in tubular components such as heat exchangers, piping systems, and surgical instruments. Their unique geometry makes them ideal for manufacturing intricate parts in high-performance environments where durability and weight savings are critical.

Cost Analysis: Nickel Bar vs Hollow Rod

Nickel bars typically incur higher material and manufacturing costs due to their solid structure, making them more expensive than nickel hollow rods. Nickel hollow rods offer cost advantages by reducing raw material usage and overall weight while maintaining sufficient strength for many industrial applications. Choosing between the two depends on the specific mechanical requirements and budget constraints of the project.

Corrosion Resistance and Durability

Nickel bars exhibit exceptional corrosion resistance, making them ideal for harsh environments where prolonged durability is essential. Nickel hollow rods offer similar corrosion resistance but provide additional benefits such as reduced weight and improved fluid dynamics for applications requiring strength with less material. Both forms maintain high durability, but the choice depends on specific structural and design requirements.

Choosing the Right Nickel Product for Your Project

Nickel bar offers solid, dense properties ideal for applications requiring high strength and resistance to wear, such as in heavy machinery or structural components. Nickel hollow rod provides advantages in weight reduction and material savings while maintaining corrosion resistance, making it suitable for lightweight frames and fluid systems. Selecting the right nickel product depends on balancing mechanical strength needs against weight considerations and specific project requirements.

Nickel Bar vs Nickel Hollow Rod Infographic

materialdif.com

materialdif.com