Nickel rods offer superior strength and are ideal for applications requiring durability and structural support, while nickel wires provide enhanced flexibility and are better suited for intricate designs and electrical uses. The choice between nickel rod and nickel wire depends on the specific demands of the project, such as mechanical strength versus conductivity and pliability. Nickel wires typically undergo more processing to achieve finer diameters, making them essential for precision work in electronics and jewelry.

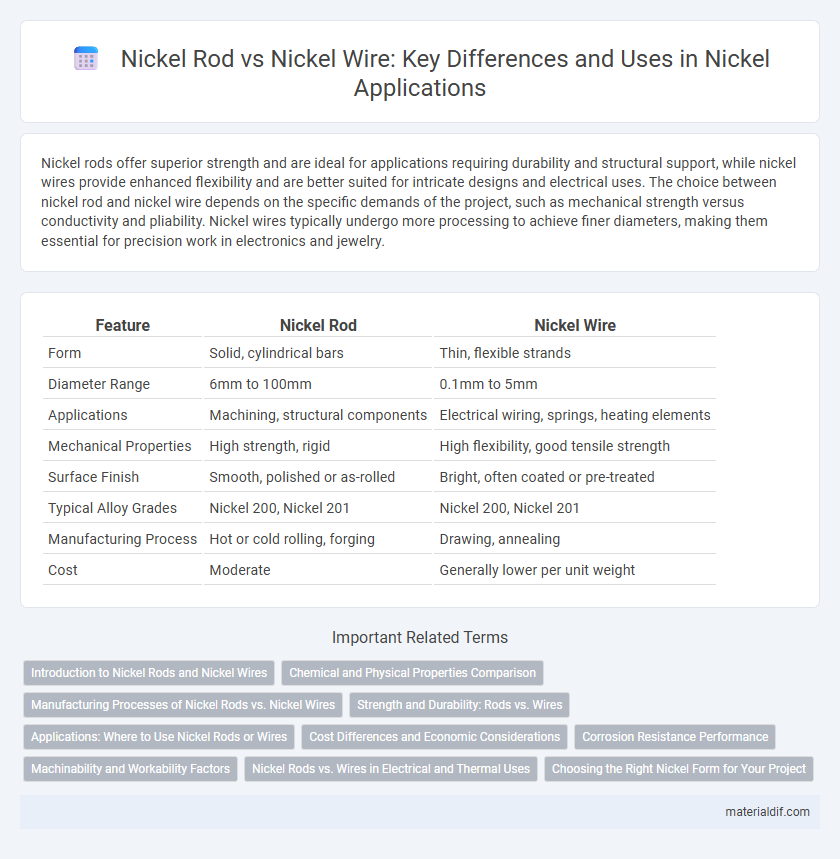

Table of Comparison

| Feature | Nickel Rod | Nickel Wire |

|---|---|---|

| Form | Solid, cylindrical bars | Thin, flexible strands |

| Diameter Range | 6mm to 100mm | 0.1mm to 5mm |

| Applications | Machining, structural components | Electrical wiring, springs, heating elements |

| Mechanical Properties | High strength, rigid | High flexibility, good tensile strength |

| Surface Finish | Smooth, polished or as-rolled | Bright, often coated or pre-treated |

| Typical Alloy Grades | Nickel 200, Nickel 201 | Nickel 200, Nickel 201 |

| Manufacturing Process | Hot or cold rolling, forging | Drawing, annealing |

| Cost | Moderate | Generally lower per unit weight |

Introduction to Nickel Rods and Nickel Wires

Nickel rods and wires are essential forms of nickel used in industrial applications, valued for their strength, corrosion resistance, and electrical conductivity. Nickel rods are typically cylindrical bars with larger diameters, ideal for machining into complex parts, while nickel wires offer flexibility and precision for electrical components and coil manufacturing. Both forms serve critical roles in aerospace, electronics, and chemical processing industries due to nickel's high melting point and durability.

Chemical and Physical Properties Comparison

Nickel rod and nickel wire share the same chemical composition, primarily consisting of 99% pure nickel with trace elements, ensuring similar corrosion resistance and magnetic properties. Physically, nickel rods typically have greater diameter and tensile strength, making them suitable for structural applications, while nickel wires offer enhanced flexibility and conductivity due to their thinner gauge and higher surface area-to-volume ratio. Both forms exhibit excellent thermal and electrical conductivity, but the mechanical form dictates their optimal use in manufacturing and electrical components.

Manufacturing Processes of Nickel Rods vs. Nickel Wires

Nickel rods are typically produced through extrusion or hot rolling methods, involving the deformation of heated nickel billets to achieve precise diameters and high structural integrity. Nickel wires are manufactured primarily via drawing processes, where thicker nickel rods or billets are pulled through successive dies to reduce diameter and enhance tensile strength and surface finish. The choice between rod extrusion and wire drawing significantly influences mechanical properties and application suitability, with rods suited for heavy-duty structural uses and wires favored in electrical and fine fabrication industries.

Strength and Durability: Rods vs. Wires

Nickel rods exhibit higher strength and durability compared to nickel wires due to their larger cross-sectional area and solid structure, making them ideal for heavy-duty applications. Nickel wires, while more flexible, tend to have lower tensile strength and are better suited for intricate or lightweight uses where flexibility is crucial. The grain structure and manufacturing process also influence the mechanical properties, with rods generally offering superior resistance to wear and deformation.

Applications: Where to Use Nickel Rods or Wires

Nickel rods are widely used in high-strength structural components and industrial equipment requiring durability and resistance to corrosion, such as aerospace parts and chemical processing machinery. Nickel wires are preferred for electrical applications, including heating elements, battery electrodes, and resistance coils, due to their excellent conductivity and flexibility. Selecting between nickel rod and wire depends on the specific mechanical and electrical requirements of the application.

Cost Differences and Economic Considerations

Nickel rods generally have a higher initial cost compared to nickel wires due to their larger mass and manufacturing process complexity. The economic considerations favor nickel wire for applications requiring flexibility and reduced material usage, offering cost savings in both raw materials and machining time. Choosing between nickel rod and wire ultimately depends on balancing upfront expenses with long-term efficiency and application-specific demands.

Corrosion Resistance Performance

Nickel rods and nickel wires both exhibit excellent corrosion resistance, but their performance can vary based on surface area and application. Nickel rods typically offer enhanced resistance in harsh environments due to their thicker cross-section, which slows down corrosive penetration. Nickel wires, with higher surface area exposure, may require protective coatings to maintain similar corrosion resistance in aggressive conditions.

Machinability and Workability Factors

Nickel rod offers superior machinability due to its uniform cross-section and larger diameter, enabling precision cutting and shaping with minimal tool wear. Nickel wire, being thinner and more flexible, excels in workability for applications requiring bending, twisting, or intricate forming. Both forms benefit from nickel's inherent corrosion resistance and high tensile strength, but rods are preferred for machining-intensive tasks while wires suit complex fabrication processes.

Nickel Rods vs. Wires in Electrical and Thermal Uses

Nickel rods exhibit superior mechanical strength and higher durability compared to nickel wires, making them ideal for structural components in electrical applications requiring stability under stress. Nickel wires offer greater flexibility and surface area, enhancing electrical conductivity and heat dissipation in thermal management systems. The choice between nickel rods and wires depends on specific requirements such as load-bearing capacity and thermal efficiency in devices like resistors, heating elements, and connectors.

Choosing the Right Nickel Form for Your Project

Nickel rods offer greater strength and resistance to deformation, making them ideal for heavy-duty applications requiring precision and durability. Nickel wires provide flexibility and ease of manipulation, suited for electrical components and intricate designs. Selecting the right nickel form depends on project requirements such as mechanical strength, conductivity, and fabrication methods.

Nickel rod vs nickel wire Infographic

materialdif.com

materialdif.com