Hot rolling nickel involves processing the metal at high temperatures, which enhances its malleability and allows for the production of thicker, more durable sheets with a rough surface finish. Cold rolling nickel is performed at or near room temperature, resulting in a smoother surface, increased strength, and tighter dimensional tolerances due to work hardening. Choosing between hot rolling and cold rolling depends on the desired mechanical properties and surface quality for specific nickel-based applications.

Table of Comparison

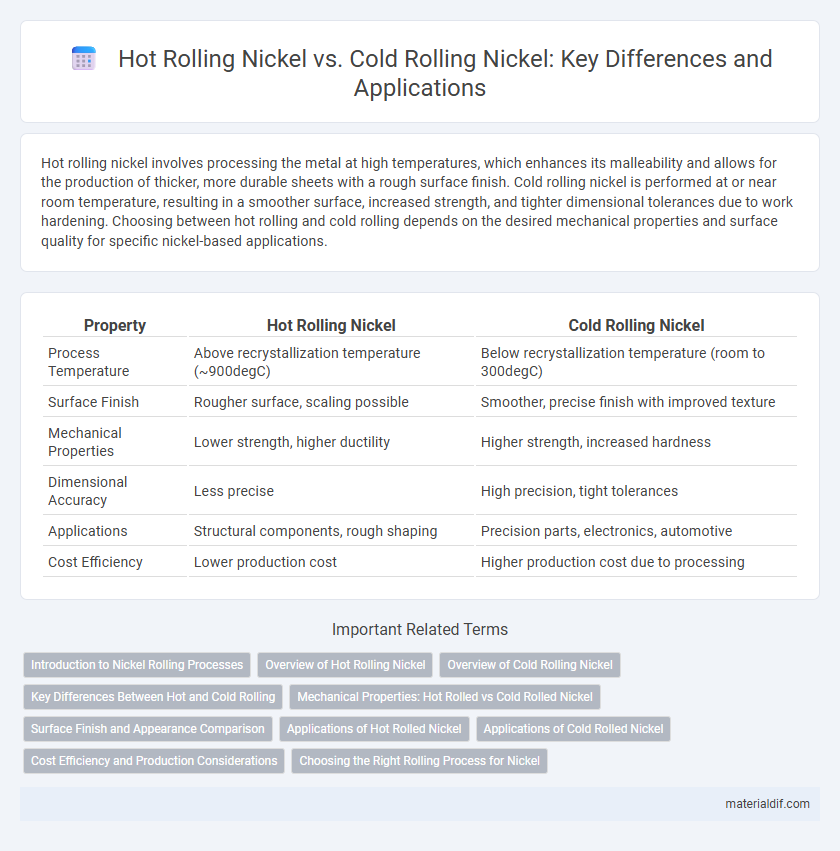

| Property | Hot Rolling Nickel | Cold Rolling Nickel |

|---|---|---|

| Process Temperature | Above recrystallization temperature (~900degC) | Below recrystallization temperature (room to 300degC) |

| Surface Finish | Rougher surface, scaling possible | Smoother, precise finish with improved texture |

| Mechanical Properties | Lower strength, higher ductility | Higher strength, increased hardness |

| Dimensional Accuracy | Less precise | High precision, tight tolerances |

| Applications | Structural components, rough shaping | Precision parts, electronics, automotive |

| Cost Efficiency | Lower production cost | Higher production cost due to processing |

Introduction to Nickel Rolling Processes

Hot rolling nickel involves heating the metal above its recrystallization temperature, allowing for easier shaping and improved ductility, resulting in thicker, rougher surface products ideal for structural applications. Cold rolling nickel is performed at or near room temperature, enhancing material strength, surface finish, and dimensional accuracy through work hardening, commonly used for precision components. Both processes play crucial roles in nickel manufacturing, with hot rolling focusing on bulk deformation and cold rolling refining mechanical properties and surface quality.

Overview of Hot Rolling Nickel

Hot rolling nickel is a metalworking process where nickel is heated above its recrystallization temperature and then passed through rollers to achieve the desired thickness and shape. This method enhances the ductility and toughness of nickel, making it ideal for producing large sheets, plates, and coils used in industrial applications such as aerospace and chemical processing. The high-temperature process also reduces internal stresses and improves grain structure, resulting in superior mechanical properties compared to cold rolling.

Overview of Cold Rolling Nickel

Cold rolling nickel involves processing the metal at room temperature to enhance its surface finish, mechanical properties, and dimensional accuracy. This method significantly increases strength and hardness through strain hardening while maintaining corrosion resistance, making it ideal for applications requiring precise tolerances and superior surface quality. Compared to hot rolling, cold rolling results in a smoother surface and improved structural integrity, which is essential for electronic components, batteries, and high-performance alloys.

Key Differences Between Hot and Cold Rolling

Hot rolling nickel involves shaping the metal at temperatures above its recrystallization point, resulting in improved ductility and reduced internal stresses, making it suitable for large structural components. Cold rolling nickel is performed below the recrystallization temperature, enhancing surface finish, dimensional accuracy, and mechanical strength due to strain hardening. Key differences include temperature of processing, resulting material properties, and typical applications where hot rolled nickel is preferred for toughness and cold rolled for precision and smoothness.

Mechanical Properties: Hot Rolled vs Cold Rolled Nickel

Hot rolled nickel typically exhibits lower tensile strength and higher ductility due to its coarser grain structure formed at elevated temperatures. Cold rolled nickel, processed at room temperature, has enhanced mechanical properties including increased yield strength and hardness, attributed to strain hardening and a refined surface finish. The choice between hot rolled and cold rolled nickel depends on the desired balance between formability and strength for specific industrial applications.

Surface Finish and Appearance Comparison

Hot rolling nickel produces a rougher surface finish characterized by scale and oxidization, requiring further processing for aesthetic or precision applications. Cold rolling nickel offers a smoother, brighter appearance with superior surface uniformity and reduced defects, making it ideal for decorative uses and components demanding high surface quality. The difference in surface finish between hot and cold rolled nickel significantly impacts their suitability for various industrial and commercial applications.

Applications of Hot Rolled Nickel

Hot rolled nickel is primarily used in industrial applications where high strength and durability are essential, such as in heavy machinery components, pressure vessels, and pipelines. Its rougher surface finish and improved workability make it suitable for forming complex shapes and large structural parts. The enhanced grain structure from hot rolling increases toughness, making it ideal for high-temperature and corrosion-resistant environments in aerospace and automotive industries.

Applications of Cold Rolled Nickel

Cold rolled nickel offers superior surface finish and tighter dimensional tolerances, making it ideal for precision applications in electronics, aerospace, and automotive industries. Its enhanced mechanical properties enable its use in battery components, medical devices, and high-performance chemical processing equipment. The smoothness and consistency of cold rolled nickel sheets improve corrosion resistance and weldability in specialized industrial applications.

Cost Efficiency and Production Considerations

Hot rolling nickel offers greater cost efficiency due to lower energy consumption and faster processing times, making it ideal for large-scale production where surface finish is less critical. Cold rolling nickel provides superior surface quality and dimensional accuracy, which increases material value but raises production costs through higher energy use and slower throughput. Manufacturers balance these factors by selecting hot rolling for bulk, structural applications and cold rolling for precision components requiring enhanced mechanical properties.

Choosing the Right Rolling Process for Nickel

Hot rolling nickel enhances ductility and reduces internal stresses by processing the metal at high temperatures above its recrystallization point, making it ideal for large-scale structural applications. Cold rolling nickel, performed below the recrystallization temperature, improves surface finish, dimensional accuracy, and mechanical strength, suitable for precision components and high-strength requirements. Selecting the appropriate rolling process depends on the desired balance between mechanical properties, surface quality, and production efficiency in nickel manufacturing.

Hot Rolling Nickel vs Cold Rolling Nickel Infographic

materialdif.com

materialdif.com