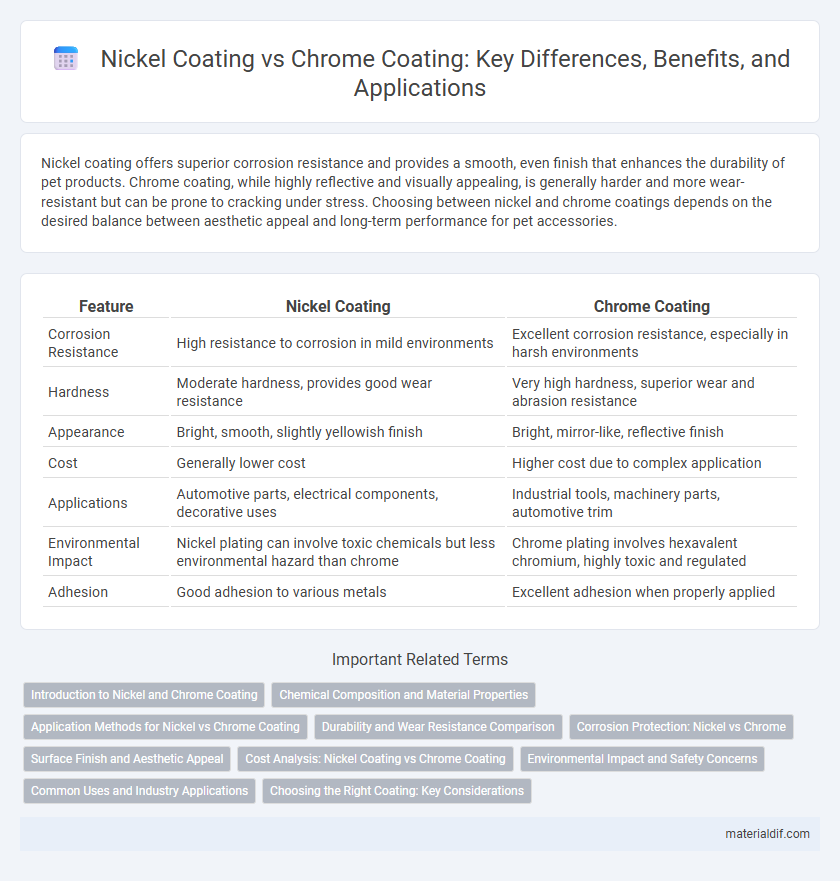

Nickel coating offers superior corrosion resistance and provides a smooth, even finish that enhances the durability of pet products. Chrome coating, while highly reflective and visually appealing, is generally harder and more wear-resistant but can be prone to cracking under stress. Choosing between nickel and chrome coatings depends on the desired balance between aesthetic appeal and long-term performance for pet accessories.

Table of Comparison

| Feature | Nickel Coating | Chrome Coating |

|---|---|---|

| Corrosion Resistance | High resistance to corrosion in mild environments | Excellent corrosion resistance, especially in harsh environments |

| Hardness | Moderate hardness, provides good wear resistance | Very high hardness, superior wear and abrasion resistance |

| Appearance | Bright, smooth, slightly yellowish finish | Bright, mirror-like, reflective finish |

| Cost | Generally lower cost | Higher cost due to complex application |

| Applications | Automotive parts, electrical components, decorative uses | Industrial tools, machinery parts, automotive trim |

| Environmental Impact | Nickel plating can involve toxic chemicals but less environmental hazard than chrome | Chrome plating involves hexavalent chromium, highly toxic and regulated |

| Adhesion | Good adhesion to various metals | Excellent adhesion when properly applied |

Introduction to Nickel and Chrome Coating

Nickel and chrome coatings are widely used for enhancing metal surfaces due to their durability and corrosion resistance. Nickel coating provides a smooth, corrosion-resistant layer that improves wear resistance and adhesion, often serving as a base layer for further coatings. Chrome coating offers a harder, more aesthetically appealing finish with excellent abrasion resistance, commonly applied for decorative and protective purposes in automotive and industrial components.

Chemical Composition and Material Properties

Nickel coating primarily consists of a nickel-phosphorus or nickel-boron alloy that provides excellent corrosion resistance and hardness, making it suitable for wear-prone applications. Chrome coating is composed mainly of hexavalent chromium, offering superior surface hardness and a distinctive, reflective finish but with reduced ductility compared to nickel. The chemical composition of nickel coatings allows for better adhesion and anti-corrosive properties, while chrome coatings excel in abrasion resistance and aesthetic appeal.

Application Methods for Nickel vs Chrome Coating

Nickel coating is commonly applied using electroplating, electroless plating, or thermal spraying, providing uniform coverage and excellent corrosion resistance for automotive, electronics, and decorative industries. Chrome coating primarily utilizes electroplating techniques, including hard and decorative chrome plating, to achieve a highly durable, wear-resistant, and reflective surface ideal for industrial machinery and automotive trim. While both coatings employ electrochemical processes, nickel's versatility in application methods offers better adaptability for complex geometries and enhanced thickness control compared to chrome.

Durability and Wear Resistance Comparison

Nickel coating offers superior corrosion resistance and excellent wear resistance, making it highly durable in harsh environments. Chrome coating provides exceptional hardness and scratch resistance but can be more brittle, potentially leading to chipping under heavy impact. For applications requiring a balance of toughness and wear resistance, nickel plating is often preferred over chrome for long-term durability.

Corrosion Protection: Nickel vs Chrome

Nickel coatings provide superior corrosion protection by forming a dense, adhesive barrier that resists oxidation and chemical degradation in harsh environments. Chrome coatings offer high hardness and aesthetic appeal but are more prone to cracking and corrosion when exposed to extreme conditions or mechanical stress. The enhanced corrosion resistance of nickel makes it the preferred choice for industrial applications requiring long-term durability and protection against rust.

Surface Finish and Aesthetic Appeal

Nickel coating offers a smooth, uniform surface finish with excellent corrosion resistance, enhancing the durability and aesthetic appeal of metal parts. Chrome coating provides a highly reflective, mirror-like finish that delivers superior brightness and hardness, making it ideal for decorative applications. While nickel excels in uniformity and subtle elegance, chrome is preferred for its brilliant shine and scratch-resistant properties.

Cost Analysis: Nickel Coating vs Chrome Coating

Nickel coating generally offers a lower initial cost compared to chrome coating, making it a budget-friendly option for corrosion resistance and decorative purposes. Chrome coating, while more expensive, provides superior hardness and wear resistance, which can reduce long-term maintenance expenses. Evaluating total lifecycle costs, nickel coating is preferred for projects with tight budgets, whereas chrome coating is cost-effective for applications demanding enhanced durability.

Environmental Impact and Safety Concerns

Nickel coating offers better corrosion resistance with lower toxicity compared to chrome coating, which involves hexavalent chromium, a known carcinogen harmful to both workers and the environment. Nickel plating processes generate fewer hazardous byproducts and require less energy, reducing overall ecological footprint and occupational health risks. Choosing nickel coating over chrome improves workplace safety and aligns with stricter environmental regulations.

Common Uses and Industry Applications

Nickel coating is widely used in electronics, automotive, and aerospace industries for corrosion resistance, wear protection, and enhancing solderability, particularly on steel and copper substrates. Chrome coating, favored in automotive parts, tools, and decorative finishes, provides superior hardness, abrasion resistance, and a reflective surface but offers less corrosion protection than nickel. Both coatings are integral in manufacturing processes where durability, aesthetic appeal, or chemical resistance is critical, with nickel often preferred for plating complex shapes and chrome for high-wear applications.

Choosing the Right Coating: Key Considerations

Nickel coating offers superior corrosion resistance and excellent adhesion on various substrates, making it ideal for applications requiring durability and wear protection. Chrome coating, valued for its high hardness and glossy finish, provides enhanced aesthetic appeal and scratch resistance but may be less effective against corrosion in aggressive environments. Selecting the right coating depends on factors such as environmental exposure, desired surface properties, and cost-effectiveness, with nickel favored for industrial use and chrome preferred for decorative or light wear applications.

Nickel coating vs Chrome coating Infographic

materialdif.com

materialdif.com