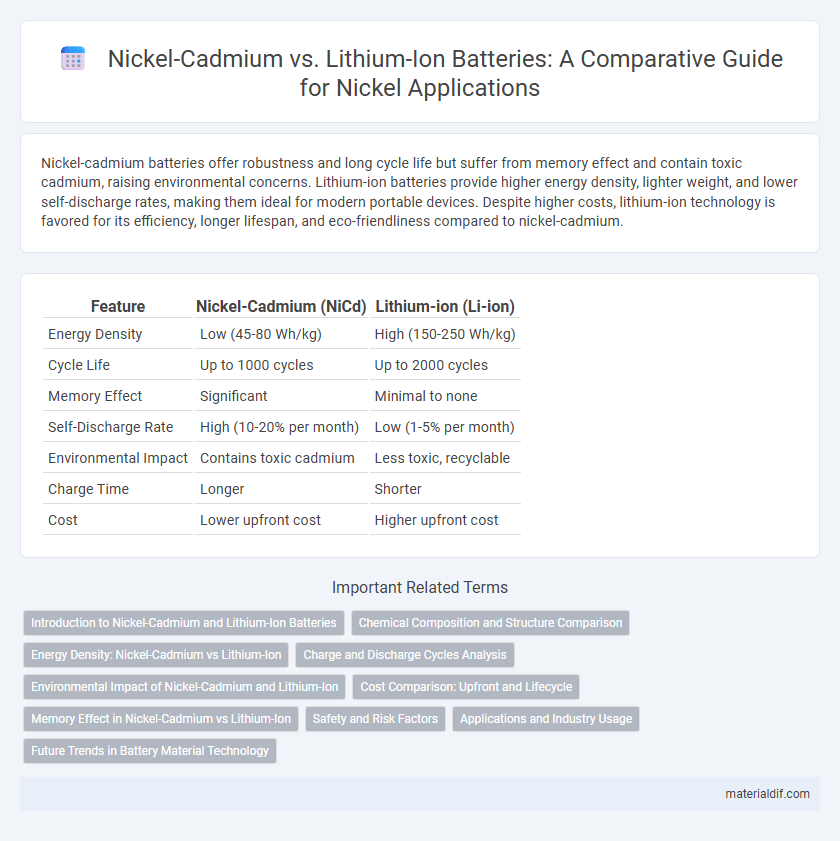

Nickel-cadmium batteries offer robustness and long cycle life but suffer from memory effect and contain toxic cadmium, raising environmental concerns. Lithium-ion batteries provide higher energy density, lighter weight, and lower self-discharge rates, making them ideal for modern portable devices. Despite higher costs, lithium-ion technology is favored for its efficiency, longer lifespan, and eco-friendliness compared to nickel-cadmium.

Table of Comparison

| Feature | Nickel-Cadmium (NiCd) | Lithium-ion (Li-ion) |

|---|---|---|

| Energy Density | Low (45-80 Wh/kg) | High (150-250 Wh/kg) |

| Cycle Life | Up to 1000 cycles | Up to 2000 cycles |

| Memory Effect | Significant | Minimal to none |

| Self-Discharge Rate | High (10-20% per month) | Low (1-5% per month) |

| Environmental Impact | Contains toxic cadmium | Less toxic, recyclable |

| Charge Time | Longer | Shorter |

| Cost | Lower upfront cost | Higher upfront cost |

Introduction to Nickel-Cadmium and Lithium-Ion Batteries

Nickel-Cadmium (Ni-Cd) batteries feature a nickel oxide hydroxide cathode and a cadmium anode, known for their durability and high discharge rates but suffer from memory effect and lower energy density. Lithium-ion batteries utilize lithium cobalt oxide or lithium iron phosphate cathodes with a graphite anode, offering superior energy density, minimal memory effect, and longer cycle life. These characteristics make Li-ion batteries the preferred choice for modern portable electronics and electric vehicles, while Ni-Cd batteries remain relevant in power tools and emergency systems due to their robustness.

Chemical Composition and Structure Comparison

Nickel-cadmium (Ni-Cd) batteries consist of nickel oxide hydroxide and metallic cadmium electrodes, where the cadmium provides robust cycle life and resistance to overcharging due to its stable crystalline structure. Lithium-ion (Li-ion) batteries use lithium cobalt oxide or lithium iron phosphate cathodes paired with graphite anodes, featuring layered crystal structures that enable higher energy density and lighter weight. The fundamental difference in chemical composition--Cd in Ni-Cd versus Li in Li-ion--directly impacts their electrochemical properties, capacity, memory effect, and environmental toxicity.

Energy Density: Nickel-Cadmium vs Lithium-Ion

Lithium-ion batteries typically offer an energy density ranging from 150 to 250 Wh/kg, significantly higher than Nickel-Cadmium batteries, which usually provide about 45 to 80 Wh/kg. This higher energy density in Lithium-ion cells results in lighter and more compact battery packs, making them ideal for portable electronics and electric vehicles. Despite this advantage, Nickel-Cadmium batteries excel in high discharge rates and durability under extreme temperatures.

Charge and Discharge Cycles Analysis

Nickel-cadmium (NiCd) batteries typically offer around 1,000 charge-discharge cycles, benefiting from robust durability and tolerance to deep discharges but suffer from lower energy density compared to lithium-ion (Li-ion) batteries. Lithium-ion batteries provide higher cycle efficiency and energy density, often delivering 500 to 1,500 cycles depending on chemistry, with superior charge retention and lower self-discharge rates, enhancing overall lifespan in applications. Detailed cycle life analysis reveals lithium-ion's advantages in sustained capacity over time, though NiCd excels in rugged environments due to its resilience against memory effect and extreme temperature variations.

Environmental Impact of Nickel-Cadmium and Lithium-Ion

Nickel-cadmium batteries contain toxic cadmium, which poses significant environmental risks during disposal due to its high toxicity and persistence in ecosystems, leading to soil and water contamination. In contrast, lithium-ion batteries have a lower environmental impact by avoiding heavy metals like cadmium, but their production involves the extraction of lithium, cobalt, and nickel, which raises concerns about resource depletion and mining-related ecological damage. Recycling processes for both battery types remain crucial to mitigating environmental harm by recovering valuable materials and reducing hazardous waste.

Cost Comparison: Upfront and Lifecycle

Nickel-cadmium batteries generally have a lower upfront cost compared to lithium-ion batteries but incur higher lifecycle expenses due to shorter lifespan and memory effect-related capacity loss. Lithium-ion batteries, despite higher initial investment, offer extended cycle life and better energy density, reducing replacement frequency and long-term operational costs. Evaluations of total cost of ownership reveal lithium-ion as more cost-effective for applications requiring durability and high performance.

Memory Effect in Nickel-Cadmium vs Lithium-Ion

Nickel-cadmium (NiCd) batteries exhibit a pronounced memory effect, where partial discharge and recharge cycles reduce their usable capacity over time, necessitating full discharge cycles to maintain performance. In contrast, lithium-ion batteries show minimal to no memory effect, allowing for flexible recharge patterns without significant capacity degradation. This characteristic makes lithium-ion batteries more efficient and user-friendly for modern applications requiring frequent and irregular charging.

Safety and Risk Factors

Nickel-cadmium (Ni-Cd) batteries pose higher safety risks due to cadmium's toxicity and the potential for thermal runaway, leading to explosion or fire hazards, especially under improper charging or physical damage. Lithium-ion (Li-ion) batteries offer a safer profile with advanced electrolyte formulations and built-in protection circuits that minimize risks such as overheating, short-circuiting, and fire, although they still require careful handling to prevent thermal incidents. The environmental impact of Ni-Cd toxicity also raises disposal concerns, making lithium-ion batteries a favorable choice for safety and sustainability in consumer electronics and electric vehicles.

Applications and Industry Usage

Nickel-cadmium batteries are widely used in industrial power tools and aviation equipment due to their durability and ability to deliver high surge currents. Lithium-ion batteries dominate consumer electronics, electric vehicles, and renewable energy storage systems because of their higher energy density, lighter weight, and longer cycle life. The shift towards lithium-ion technology is driven by industries prioritizing efficiency, reduced environmental impact, and improved performance in portable and high-demand applications.

Future Trends in Battery Material Technology

Future trends in battery material technology highlight a shift from nickel-cadmium to lithium-ion batteries due to lithium-ion's higher energy density, longer cycle life, and lower environmental impact. Research on nickel-rich cathodes aims to improve lithium-ion performance by increasing energy capacity while maintaining stability. Development of solid-state electrolytes and recycling technologies further drives innovation, reducing reliance on cobalt and enhancing sustainability in battery production.

Nickel-cadmium vs Lithium-ion Infographic

materialdif.com

materialdif.com