Hard nickel offers superior durability and corrosion resistance, making it ideal for industrial applications requiring long-lasting performance. Soft nickel, with its more pliable and malleable nature, is commonly used in plating and decorative purposes where flexibility and aesthetic appeal are important. Choosing between hard and soft nickel depends on balancing mechanical strength with ease of application for specific project requirements.

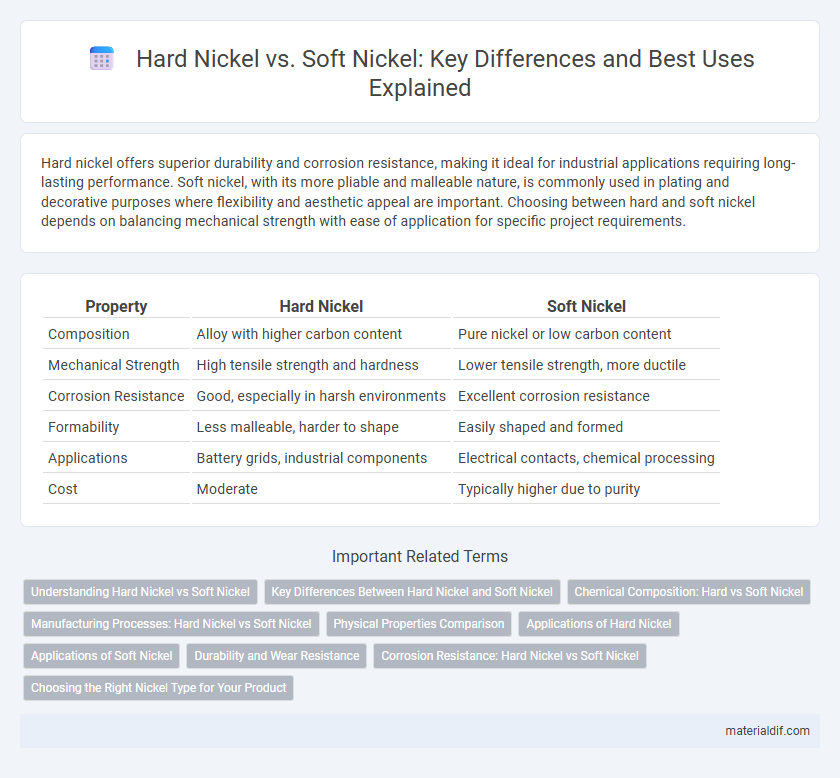

Table of Comparison

| Property | Hard Nickel | Soft Nickel |

|---|---|---|

| Composition | Alloy with higher carbon content | Pure nickel or low carbon content |

| Mechanical Strength | High tensile strength and hardness | Lower tensile strength, more ductile |

| Corrosion Resistance | Good, especially in harsh environments | Excellent corrosion resistance |

| Formability | Less malleable, harder to shape | Easily shaped and formed |

| Applications | Battery grids, industrial components | Electrical contacts, chemical processing |

| Cost | Moderate | Typically higher due to purity |

Understanding Hard Nickel vs Soft Nickel

Hard nickel exhibits higher tensile strength and wear resistance, making it ideal for industrial applications requiring durability such as battery electrodes and plating. Soft nickel offers superior ductility and electrical conductivity, benefiting processes needing malleability like foil production and electrical components. Understanding these distinctions is crucial for selecting the right nickel type based on mechanical properties and application requirements.

Key Differences Between Hard Nickel and Soft Nickel

Hard nickel contains a higher percentage of iron and other alloying elements, resulting in greater tensile strength and wear resistance compared to soft nickel. Soft nickel, typically purer with minimal impurities, offers superior ductility and corrosion resistance, making it ideal for applications requiring malleability and exposure to harsh environments. The choice between hard and soft nickel depends on the specific mechanical properties needed, such as hardness for durability or softness for formability and corrosion protection.

Chemical Composition: Hard vs Soft Nickel

Hard nickel contains a higher percentage of copper and a small amount of iron, which enhances its strength and hardness compared to soft nickel. Soft nickel is primarily composed of nearly pure nickel, with minimal impurities, resulting in greater ductility and malleability. The chemical composition differences directly influence their industrial applications, with hard nickel suited for durable plating and soft nickel used in electroplating and battery manufacturing.

Manufacturing Processes: Hard Nickel vs Soft Nickel

Hard nickel and soft nickel differ significantly in their manufacturing processes, impacting their physical properties and industrial applications. Hard nickel undergoes electroplating with higher phosphorus content, resulting in a tougher, more wear-resistant coating ideal for tooling and industrial machinery. Soft nickel plating contains lower phosphorus, producing a ductile and corrosion-resistant layer suitable for decorative purposes and electrical components.

Physical Properties Comparison

Hard nickel exhibits higher tensile strength and greater hardness compared to soft nickel, making it ideal for applications requiring durability and wear resistance. Soft nickel has superior ductility and malleability, allowing easier shaping and forming without cracking. The density of both types remains similar, approximately 8.9 g/cm3, but their differing microstructures directly influence mechanical behavior and suitability for specific industrial uses.

Applications of Hard Nickel

Hard nickel, characterized by its high tensile strength and resistance to wear, is widely used in electroplating to provide durable, corrosion-resistant coatings for industrial machinery, automotive parts, and aerospace components. Its hardness makes it ideal for applications requiring abrasion resistance, such as in manufacturing tools, printing rollers, and hard-facing of metal parts. The enhanced mechanical properties of hard nickel coatings extend the service life of equipment exposed to harsh environments and high friction.

Applications of Soft Nickel

Soft nickel's malleability and excellent corrosion resistance make it ideal for applications in plating, batteries, and flexible electronic components. Its ability to form thin, ductile layers enhances the durability and conductivity of electrical contacts and connectors. Industries such as automotive, aerospace, and consumer electronics frequently utilize soft nickel for protective coatings and electrode materials.

Durability and Wear Resistance

Hard nickel alloys exhibit superior durability and wear resistance compared to soft nickel grades, making them ideal for applications involving high mechanical stress and abrasive environments. The increased hardness in hard nickel results from higher carbon content and specific heat treatment processes that enhance its resistance to deformation and surface damage. Soft nickel, with lower hardness, offers better ductility but compromises on wear resistance, limiting its use in heavy-duty industrial components.

Corrosion Resistance: Hard Nickel vs Soft Nickel

Hard nickel offers superior corrosion resistance compared to soft nickel due to its denser microstructure and higher hardness, which provide enhanced protection against oxidation and chemical degradation. Soft nickel, being more ductile and less dense, is more prone to surface damage and corrosion in harsh environments. Industrial applications demanding long-term durability and corrosion resistance typically favor hard nickel plating for its robust protective qualities.

Choosing the Right Nickel Type for Your Product

Hard nickel offers increased durability and corrosion resistance, making it ideal for applications requiring longevity and mechanical strength, such as plating automotive parts or electronics. Soft nickel provides better malleability and conductivity, which is crucial for products involving electrical components or intricate metal forming. Selecting the right nickel type depends on the specific performance requirements and manufacturing processes of your product to ensure optimal functionality and cost-efficiency.

Hard Nickel vs Soft Nickel Infographic

materialdif.com

materialdif.com