Nickel Metal Hydride (NiMH) batteries offer reliable performance with a high capacity-to-weight ratio and enhanced safety, making them ideal for various pet devices requiring moderate energy demands. Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries provide higher energy density and longer cycle life, delivering superior power output crucial for advanced pet monitoring systems with extended usage. Choosing between NiMH and NCA depends on balancing energy needs, weight constraints, and cost considerations in pet technology applications.

Table of Comparison

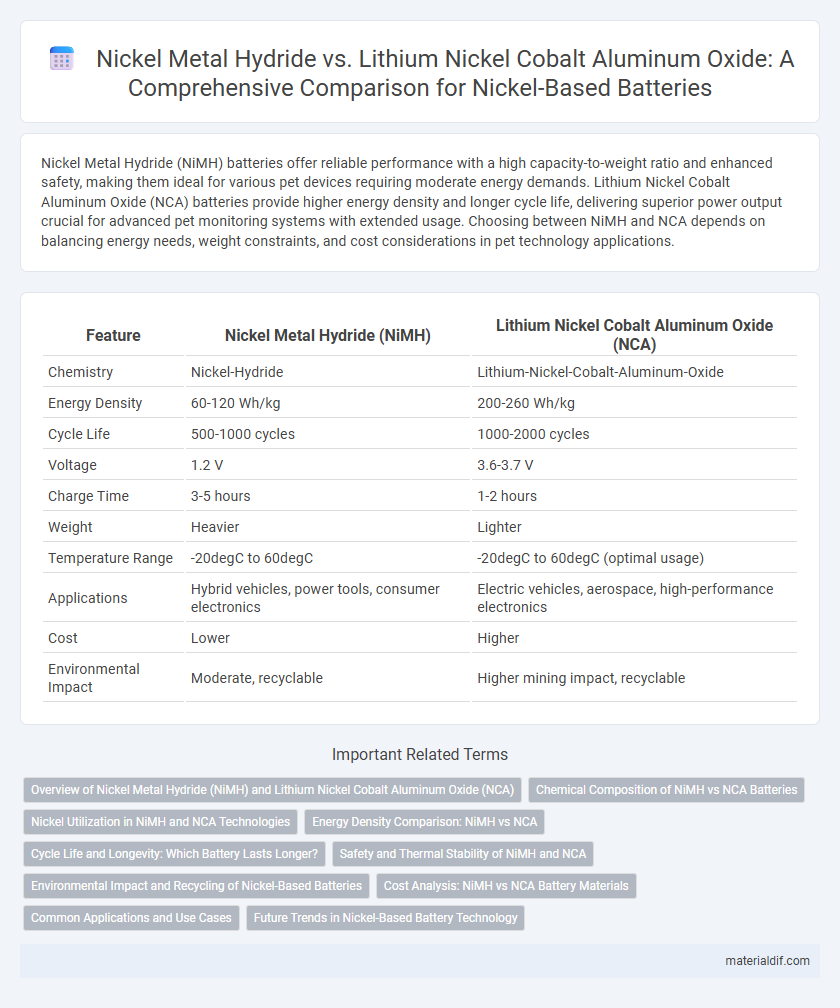

| Feature | Nickel Metal Hydride (NiMH) | Lithium Nickel Cobalt Aluminum Oxide (NCA) |

|---|---|---|

| Chemistry | Nickel-Hydride | Lithium-Nickel-Cobalt-Aluminum-Oxide |

| Energy Density | 60-120 Wh/kg | 200-260 Wh/kg |

| Cycle Life | 500-1000 cycles | 1000-2000 cycles |

| Voltage | 1.2 V | 3.6-3.7 V |

| Charge Time | 3-5 hours | 1-2 hours |

| Weight | Heavier | Lighter |

| Temperature Range | -20degC to 60degC | -20degC to 60degC (optimal usage) |

| Applications | Hybrid vehicles, power tools, consumer electronics | Electric vehicles, aerospace, high-performance electronics |

| Cost | Lower | Higher |

| Environmental Impact | Moderate, recyclable | Higher mining impact, recyclable |

Overview of Nickel Metal Hydride (NiMH) and Lithium Nickel Cobalt Aluminum Oxide (NCA)

Nickel Metal Hydride (NiMH) batteries utilize a hydrogen-absorbing alloy as the negative electrode and nickel oxyhydroxide as the positive electrode, offering moderate energy density and excellent thermal stability. Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries, featuring a cathode composition of nickel, cobalt, and aluminum, deliver significantly higher energy density, longer cycle life, and enhanced power output suitable for electric vehicles and high-performance applications. NiMH batteries excel in safety and environmental impact, while NCA batteries prioritize energy efficiency and weight reduction for advanced lithium-ion technologies.

Chemical Composition of NiMH vs NCA Batteries

Nickel Metal Hydride (NiMH) batteries use a hydrogen-absorbing alloy as the negative electrode and nickel oxide hydroxide as the positive electrode, with an alkaline electrolyte typically composed of potassium hydroxide. Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries consist of a lithium nickel cobalt aluminum oxide cathode and a graphite anode, relying on a lithium-ion electrolyte for charge transfer. The chemical composition differences influence energy density, cycle life, and thermal stability, with NCA's lithium-based chemistry providing higher voltage and energy density compared to NiMH's metal hydride system.

Nickel Utilization in NiMH and NCA Technologies

Nickel utilization in Nickel Metal Hydride (NiMH) batteries centers on its role in the hydrogen-absorbing alloys that enable high energy density and long cycle life. Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries leverage a higher percentage of nickel in the cathode chemistry, enhancing energy density and power output while reducing cobalt content for improved cost-effectiveness and sustainability. NiMH technology benefits from nickel's stable electrochemical properties in alloy form, whereas NCA's nickel-rich cathodes drive advancements in electric vehicle performance and energy storage solutions.

Energy Density Comparison: NiMH vs NCA

Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries offer significantly higher energy density compared to Nickel Metal Hydride (NiMH) batteries, typically ranging from 200 to 260 Wh/kg for NCA versus 60 to 120 Wh/kg for NiMH. This higher energy density enables longer battery life and greater energy storage capacity, making NCA batteries more suitable for electric vehicles and high-performance applications. Despite NiMH batteries' advantages in safety and cost, NCA's superior energy density provides critical efficiency improvements in weight-sensitive technologies.

Cycle Life and Longevity: Which Battery Lasts Longer?

Nickel Metal Hydride (NiMH) batteries typically offer a cycle life of around 500 to 1000 cycles, making them suitable for moderate-duration applications. Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries provide a higher cycle life, often exceeding 1000 to 2000 cycles, due to their advanced cathode chemistry that enhances energy density and thermal stability. For longevity and extended usage, NCA batteries generally outperform NiMH cells, making them preferable in electric vehicles and high-demand energy storage systems.

Safety and Thermal Stability of NiMH and NCA

Nickel Metal Hydride (NiMH) batteries exhibit superior thermal stability compared to Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries, making NiMH safer under high-temperature conditions due to their reduced risk of thermal runaway. NiMH cells generate lower heat during charging and discharging cycles, enhancing overall safety in consumer and automotive applications. In contrast, NCA batteries, while providing higher energy density, require sophisticated battery management systems to mitigate thermal instability and potential fire hazards.

Environmental Impact and Recycling of Nickel-Based Batteries

Nickel Metal Hydride (NiMH) batteries feature a lower environmental impact due to their use of less toxic materials and higher recyclability rates compared to Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries. NCA batteries contain cobalt and aluminum, making recycling processes more complex and energy-intensive, while NiMH batteries benefit from established nickel recycling infrastructure that reduces landfill waste. Efficient recycling of nickel-based batteries significantly lowers the demand for raw nickel mining, mitigating ecological damage and conserving natural resources.

Cost Analysis: NiMH vs NCA Battery Materials

Nickel Metal Hydride (NiMH) batteries generally have lower raw material costs compared to Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries due to the absence of expensive cobalt and aluminum components. NiMH batteries utilize abundant nickel and rare earth metals, which fluctuate less in price than the critical materials found in NCA chemistry. Despite NCA's higher energy density and performance, the premium for cobalt and aluminum drives up production expenses, impacting the overall cost-effectiveness in large-scale applications.

Common Applications and Use Cases

Nickel Metal Hydride (NiMH) batteries are prevalent in hybrid vehicles, cordless power tools, and consumer electronics due to their safety, cost-effectiveness, and moderate energy density. Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries are widely used in electric vehicles, aerospace, and grid storage applications, offering higher energy density, longer lifespan, and superior power output. NiMH suits environments with moderate energy needs and robustness, while NCA excels where weight, efficiency, and extended range are critical.

Future Trends in Nickel-Based Battery Technology

Nickel Metal Hydride (NiMH) batteries, valued for their stability and recyclability, face competition from Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries, which offer higher energy density and longer lifespan, driving demand for nickel-based cathode materials. Future trends emphasize improving nickel purity and optimizing cathode formulations to enhance battery performance while reducing cobalt reliance, crucial for sustainable electric vehicle production. Advances in solid-state electrolytes and recycling technologies aim to further boost the efficiency and environmental footprint of nickel-based energy storage solutions.

Nickel Metal Hydride vs Lithium Nickel Cobalt Aluminum Oxide Infographic

materialdif.com

materialdif.com