Forging nickel produces parts with superior strength and durability due to the refined grain structure formed under high pressure, making it ideal for high-stress applications. Casting nickel allows for complex shapes and intricate designs with greater manufacturing flexibility but may have lower mechanical properties and require post-processing to enhance performance. Choosing between forging and casting depends on application requirements, balancing material properties and design complexity.

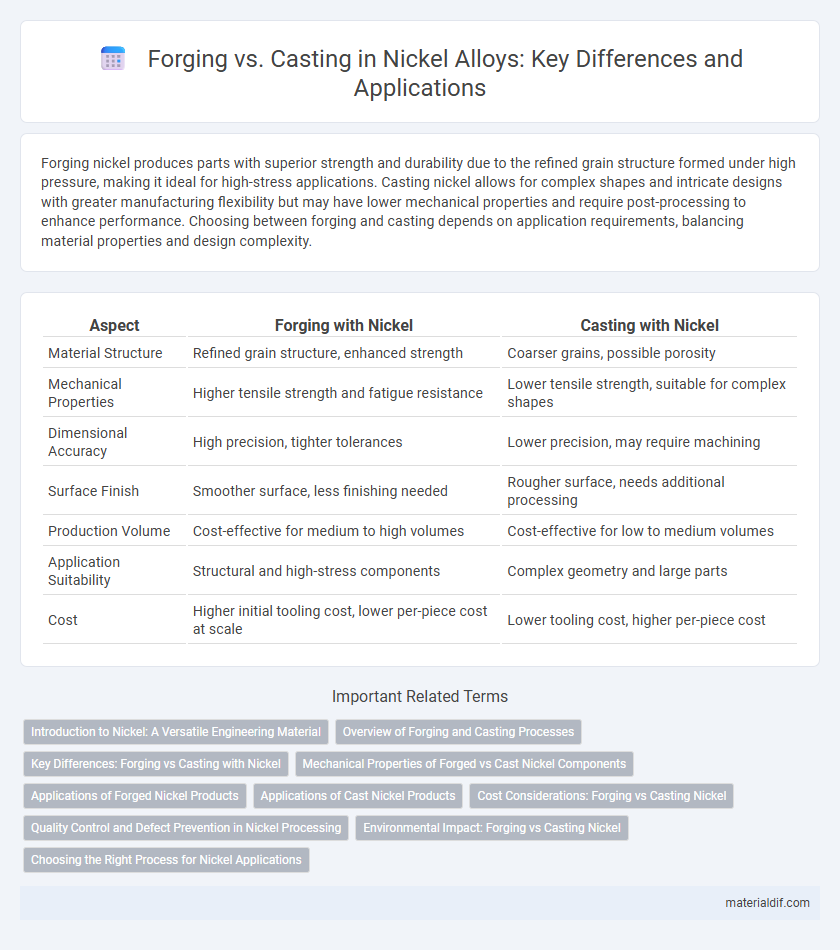

Table of Comparison

| Aspect | Forging with Nickel | Casting with Nickel |

|---|---|---|

| Material Structure | Refined grain structure, enhanced strength | Coarser grains, possible porosity |

| Mechanical Properties | Higher tensile strength and fatigue resistance | Lower tensile strength, suitable for complex shapes |

| Dimensional Accuracy | High precision, tighter tolerances | Lower precision, may require machining |

| Surface Finish | Smoother surface, less finishing needed | Rougher surface, needs additional processing |

| Production Volume | Cost-effective for medium to high volumes | Cost-effective for low to medium volumes |

| Application Suitability | Structural and high-stress components | Complex geometry and large parts |

| Cost | Higher initial tooling cost, lower per-piece cost at scale | Lower tooling cost, higher per-piece cost |

Introduction to Nickel: A Versatile Engineering Material

Nickel exhibits exceptional strength and corrosion resistance, making it ideal for both forging and casting processes in engineering applications. Forging nickel enhances its mechanical properties, such as toughness and fatigue resistance, through controlled deformation and grain refinement. Casting nickel allows for complex shapes and intricate designs, maintaining its durability and thermal stability in demanding environments.

Overview of Forging and Casting Processes

Forging nickel involves deforming the metal under high pressure, enhancing its grain structure and mechanical properties, which results in superior strength and toughness. Casting nickel, on the other hand, entails melting the metal and pouring it into molds to achieve complex shapes, though it may introduce porosity and lower mechanical integrity compared to forging. The choice between forging and casting nickel depends on the application requirements, balancing factors such as strength, complexity, and production cost.

Key Differences: Forging vs Casting with Nickel

Forging nickel involves shaping the metal through compressive forces, resulting in improved grain structure and enhanced mechanical properties such as higher strength and toughness. Casting nickel entails pouring molten metal into molds, allowing complex geometries but often producing coarser grain structure and potential porosity issues. Forged nickel components typically exhibit superior fatigue resistance and durability compared to cast nickel parts, making them preferable in high-stress applications.

Mechanical Properties of Forged vs Cast Nickel Components

Forged nickel components exhibit superior mechanical properties such as higher tensile strength, improved fatigue resistance, and enhanced ductility compared to cast counterparts due to the refined grain structure formed during the forging process. In contrast, cast nickel parts often contain porosity and a coarser microstructure, leading to reduced toughness and increased susceptibility to cracking under stress. The controlled deformation in forging aligns the metal grains, resulting in components better suited for high-stress aerospace and industrial applications.

Applications of Forged Nickel Products

Forged nickel products are extensively used in aerospace and power generation industries due to their superior strength, durability, and resistance to high temperatures and corrosion. Components such as turbine blades, jet engine parts, and chemical processing equipment benefit from the refined grain structure and enhanced mechanical properties achieved through forging. Forging nickel alloys also ensures consistent quality and reliability in critical applications where performance under extreme conditions is essential.

Applications of Cast Nickel Products

Cast nickel products are widely used in aerospace components, chemical processing equipment, and power generation systems due to their excellent corrosion resistance and high-temperature strength. The casting process allows for the creation of complex geometries and large, durable parts such as turbine blades, valve bodies, and pump housings. These applications benefit from cast nickel's superior mechanical properties and resistance to thermal fatigue in harsh environments.

Cost Considerations: Forging vs Casting Nickel

Forging nickel typically incurs higher initial costs due to expensive equipment and skilled labor but results in superior mechanical properties and durability, which can reduce long-term expenses. Casting nickel offers lower upfront costs and greater design flexibility, making it cost-effective for complex shapes and small production runs despite potential compromises in material strength. Selecting between forging and casting nickel depends on balancing immediate budget constraints against performance requirements and lifecycle cost savings.

Quality Control and Defect Prevention in Nickel Processing

Forging nickel enhances grain structure and mechanical properties, leading to improved quality control through uniformity and reduced porosity compared to casting. Casting nickel often faces challenges like shrinkage cavities and gas porosity, necessitating rigorous defect prevention measures such as controlled cooling rates and molten metal degassing. Implementing non-destructive testing methods including ultrasonic inspection and X-ray tomography is critical in both forging and casting to detect subsurface defects and ensure material integrity.

Environmental Impact: Forging vs Casting Nickel

Forging nickel generally has a lower environmental impact than casting due to reduced energy consumption and fewer emissions during the deformation process. Casting nickel involves melting the metal, which requires higher temperatures and results in increased greenhouse gas emissions and potential waste from mold materials. Additionally, forging produces less scrap and typically enables more efficient material usage, contributing to enhanced sustainability in nickel manufacturing.

Choosing the Right Process for Nickel Applications

Forging nickel improves its mechanical properties by refining grain structure, enhancing strength and fatigue resistance, making it ideal for demanding aerospace and industrial components. Casting nickel allows complex shapes and sizes at a lower cost but may introduce porosity and less uniformity in microstructure, affecting performance in high-stress environments. Selecting forging or casting for nickel depends on the application's strength requirements, complexity, and budget constraints to optimize performance and durability.

Forging vs Casting (with Nickel) Infographic

materialdif.com

materialdif.com