Sintering nickel involves heating powdered nickel below its melting point to create a solid mass with controlled porosity and uniform microstructure, ideal for precision components in the battery and electronics industries. Forging nickel, on the other hand, applies compressive forces to shape solid nickel, resulting in enhanced mechanical strength and toughness suitable for heavy-duty applications like aerospace and automotive parts. Choosing between sintered and forged nickel depends on the required material properties, component complexity, and specific application demands.

Table of Comparison

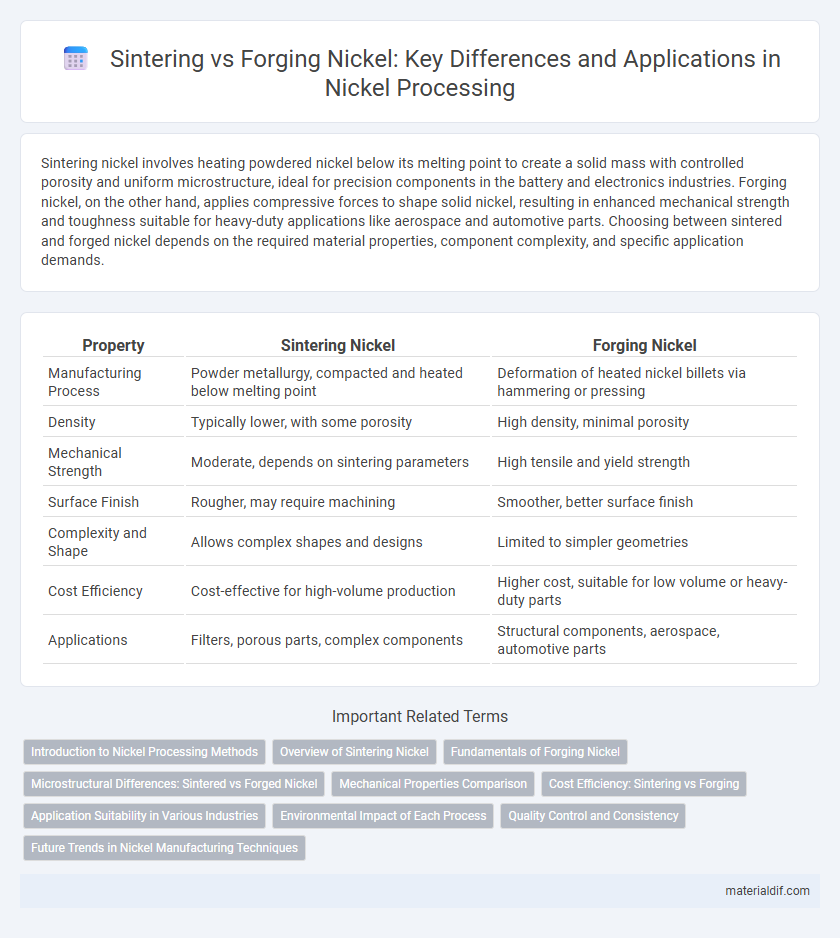

| Property | Sintering Nickel | Forging Nickel |

|---|---|---|

| Manufacturing Process | Powder metallurgy, compacted and heated below melting point | Deformation of heated nickel billets via hammering or pressing |

| Density | Typically lower, with some porosity | High density, minimal porosity |

| Mechanical Strength | Moderate, depends on sintering parameters | High tensile and yield strength |

| Surface Finish | Rougher, may require machining | Smoother, better surface finish |

| Complexity and Shape | Allows complex shapes and designs | Limited to simpler geometries |

| Cost Efficiency | Cost-effective for high-volume production | Higher cost, suitable for low volume or heavy-duty parts |

| Applications | Filters, porous parts, complex components | Structural components, aerospace, automotive parts |

Introduction to Nickel Processing Methods

Sintering nickel involves compacting nickel powders and heating them below melting points to create dense, intricate parts with controlled porosity and mechanical properties, optimizing performance in electronics and battery applications. Forging nickel, on the other hand, entails deforming solid nickel billets under high pressure and temperature to enhance strength and grain structure for critical aerospace and industrial applications. Both processing methods tailor nickel's microstructure to meet specific mechanical and functional requirements efficiently.

Overview of Sintering Nickel

Sintering nickel involves compacting and heating nickel powder below its melting point to create dense, porous structures ideal for applications requiring high wear resistance and precise dimensional control. This process enhances mechanical properties by promoting grain bonding and uniform microstructure without significant deformation. Sintered nickel components are commonly used in electronics, aerospace, and automotive industries for their strength, corrosion resistance, and lightweight characteristics.

Fundamentals of Forging Nickel

Forging nickel involves shaping the metal through controlled deformation processes such as hammering or pressing, which refines its grain structure and enhances mechanical properties like strength and toughness. Unlike sintering nickel, which consolidates powdered metal at high temperatures without melting, forging applies significant pressure to reshape solid billets, resulting in superior density and reduced porosity. The fundamental advantage of forging nickel lies in its ability to produce components with improved structural integrity, fatigue resistance, and dimensional accuracy suitable for high-stress applications.

Microstructural Differences: Sintered vs Forged Nickel

Sintered nickel exhibits a porous microstructure formed by compacted nickel powder particles fused at elevated temperatures, resulting in controlled porosity and uniform grain distribution that enhances specific mechanical properties like wear resistance. Forged nickel, conversely, features a dense, non-porous microstructure with elongated grains aligned by deformation during forging, increasing strength and toughness through grain refinement and work hardening. These microstructural distinctions influence application-specific performance, with sintered nickel favored for filtration and catalytic components, while forged nickel suits high-strength structural applications.

Mechanical Properties Comparison

Sintering nickel produces a material with uniform microstructure and fine grain size, resulting in enhanced wear resistance and moderate tensile strength ideal for precision components. Forging nickel yields a denser, more ductile structure with superior impact toughness and higher fatigue strength, suitable for heavy-duty applications requiring exceptional mechanical resilience. The choice between sintering and forging directly impacts hardness, tensile strength, and fracture toughness, with forging generally achieving higher mechanical robustness.

Cost Efficiency: Sintering vs Forging

Sintering nickel offers significant cost efficiency compared to forging due to lower energy consumption and reduced material waste during production. Forging nickel involves higher tooling and labor expenses, making it less economical for complex or high-volume parts. Overall, sintering optimizes manufacturing costs while maintaining material properties suitable for various industrial applications.

Application Suitability in Various Industries

Sintering nickel offers superior precision and uniformity, making it ideal for high-performance electronics, aerospace components, and intricate automotive parts where tight tolerances are critical. Forging nickel provides enhanced mechanical strength and durability, suitable for heavy-duty applications in power generation, oil and gas, and marine industries requiring robust structural integrity. Choosing between sintered and forged nickel depends on the specific industry demands for dimensional accuracy versus strength and toughness.

Environmental Impact of Each Process

Sintering nickel typically results in lower energy consumption and reduced greenhouse gas emissions compared to forging, as it operates at lower temperatures and employs powder metallurgy techniques that minimize material waste. Forging nickel requires higher temperatures and substantial mechanical force, leading to increased carbon emissions and greater energy usage due to prolonged heating periods. Both processes impact environmental sustainability, but sintering offers a more eco-friendly profile by decreasing overall energy demand and reducing the carbon footprint associated with nickel production.

Quality Control and Consistency

Sintering nickel ensures uniform microstructure and consistent mechanical properties through precise powder metallurgy control, resulting in improved dimensional accuracy and reduced defects. Forging nickel, while enhancing strength and toughness via plastic deformation, demands rigorous quality control measures to monitor grain flow and detect potential inconsistencies or internal stresses. Consistency in sintered nickel is achieved by controlled sintering temperatures and atmospheres, whereas forged nickel relies heavily on strict temperature and deformation rate regulation to maintain quality standards.

Future Trends in Nickel Manufacturing Techniques

Sintering nickel offers enhanced microstructural control and superior uniformity, making it highly suitable for advanced applications requiring precision and consistency in material properties. Forging nickel, while providing exceptional mechanical strength and toughness, faces challenges in scalability and material efficiency, prompting industries to explore hybrid techniques that combine both methods. Future trends in nickel manufacturing emphasize additive manufacturing integration, microstructural engineering, and environmentally sustainable processes to optimize performance and reduce production costs.

Sintering Nickel vs Forging Nickel Infographic

materialdif.com

materialdif.com