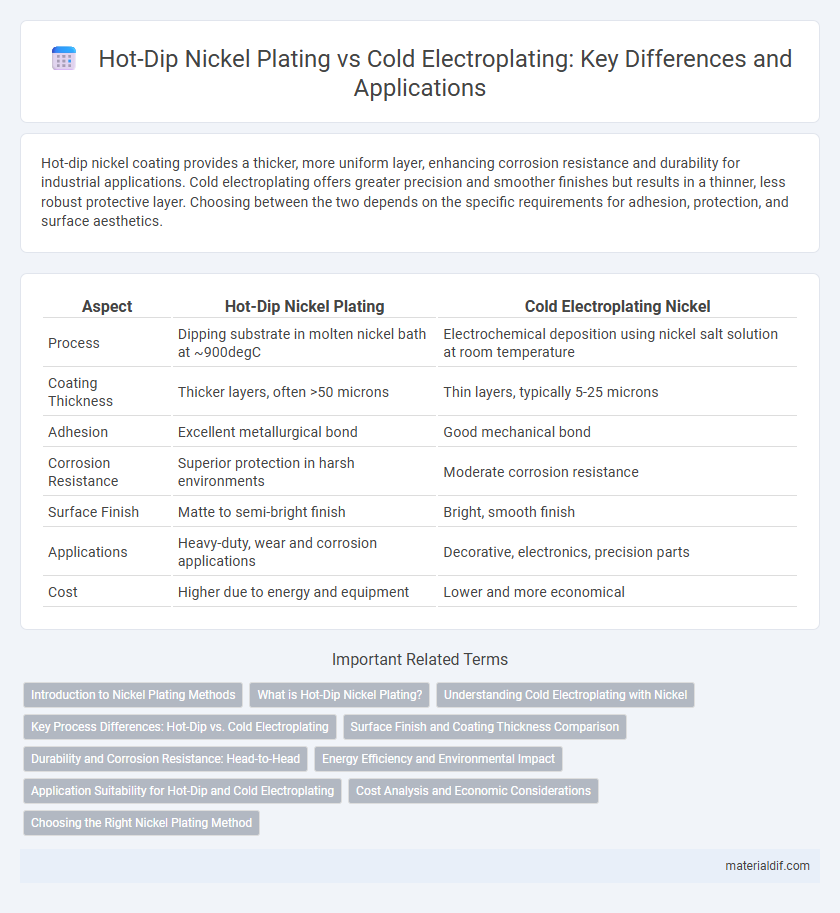

Hot-dip nickel coating provides a thicker, more uniform layer, enhancing corrosion resistance and durability for industrial applications. Cold electroplating offers greater precision and smoother finishes but results in a thinner, less robust protective layer. Choosing between the two depends on the specific requirements for adhesion, protection, and surface aesthetics.

Table of Comparison

| Aspect | Hot-Dip Nickel Plating | Cold Electroplating Nickel |

|---|---|---|

| Process | Dipping substrate in molten nickel bath at ~900degC | Electrochemical deposition using nickel salt solution at room temperature |

| Coating Thickness | Thicker layers, often >50 microns | Thin layers, typically 5-25 microns |

| Adhesion | Excellent metallurgical bond | Good mechanical bond |

| Corrosion Resistance | Superior protection in harsh environments | Moderate corrosion resistance |

| Surface Finish | Matte to semi-bright finish | Bright, smooth finish |

| Applications | Heavy-duty, wear and corrosion applications | Decorative, electronics, precision parts |

| Cost | Higher due to energy and equipment | Lower and more economical |

Introduction to Nickel Plating Methods

Hot-dip nickel plating involves immersing a metal substrate into molten nickel, creating a thick, corrosion-resistant coating ideal for heavy-duty applications. Cold electroplating deposits nickel ions onto the surface through an electrolytic process at room temperature, offering precise thickness control and superior surface finish. Each method provides distinct advantages depending on factors like desired coating thickness, durability, and application environment.

What is Hot-Dip Nickel Plating?

Hot-dip nickel plating is a metallurgical process where a steel or iron substrate is immersed in molten nickel at temperatures around 900degC, creating a thick, metallurgically bonded coating that offers superior corrosion resistance and wear protection. This method produces a uniform, dense nickel layer with excellent adhesion and hardness compared to cold electroplating, which deposits nickel at ambient temperatures using an electrolytic bath. Hot-dip nickel plating enhances longevity in industrial applications such as automotive parts, valves, and tooling, where high durability and resistance to extreme environments are critical.

Understanding Cold Electroplating with Nickel

Cold electroplating with nickel involves depositing a thin, uniform nickel layer onto a substrate at lower temperatures, preserving the material's integrity and preventing thermal distortion common in hot-dip nickel plating. This electrochemical process controls thickness and surface finish precisely, enhancing corrosion resistance and wear properties on delicate components. The technique is particularly valued in electronics and precision engineering where dimensional tolerances and surface quality are critical.

Key Process Differences: Hot-Dip vs. Cold Electroplating

Hot-dip nickel plating involves immersing the substrate into molten nickel at temperatures typically around 900degC, creating a thick, metallurgically bonded coating that offers superior corrosion resistance and wear protection. Cold electroplating deposits nickel ions from an aqueous electrolyte solution onto the substrate surface at ambient temperatures, resulting in a thinner, more uniform layer ideal for precise thickness control and decorative finishes. The primary process differences lie in temperature, coating thickness, bonding mechanism, and application suitability, with hot-dip favoring industrial durability and cold electroplating suited for detailed, controlled coatings.

Surface Finish and Coating Thickness Comparison

Hot-dip nickel plating typically produces a thicker coating, ranging from 25 to 150 microns, resulting in a more robust and corrosion-resistant surface finish suitable for heavy-duty applications. Cold electroplating usually achieves thinner layers, between 1 to 25 microns, offering a smoother and more uniform surface finish ideal for decorative purposes and precise dimensional tolerances. The difference in deposition methods causes hot-dip nickel to exhibit higher surface roughness, while cold electroplating provides finer grain structures and enhanced brightness.

Durability and Corrosion Resistance: Head-to-Head

Hot-dip nickel plating provides superior durability and corrosion resistance due to its thicker and more uniform coating compared to cold electroplating, which typically results in a thinner and less robust layer. The hot-dip process creates a metallurgically bonded layer that enhances protection against wear, oxidation, and chemical exposure, making it ideal for harsh industrial environments. Cold electroplating offers finer surface finishes but lacks the long-term corrosion resistance and mechanical strength of hot-dip nickel coatings.

Energy Efficiency and Environmental Impact

Hot-dip nickel plating consumes more energy due to the high temperatures required for the molten nickel bath, whereas cold electroplating operates at lower temperatures, resulting in reduced energy consumption. Environmentally, hot-dip nickel plating generates hazardous waste laden with heavy metals and requires careful disposal, while cold electroplating typically produces less hazardous waste but may involve toxic chemical baths that demand stringent waste management. Choosing cold electroplating can enhance energy efficiency and minimize the environmental footprint when proper waste treatment protocols are followed.

Application Suitability for Hot-Dip and Cold Electroplating

Hot-dip nickel coating provides superior corrosion resistance and is ideal for heavy-duty applications such as automotive parts, industrial equipment, and outdoor structures exposed to harsh environments. Cold electroplating offers finer surface finishes and greater control over thickness, making it suitable for decorative purposes, electronic components, and precision instruments. Choosing between hot-dip nickel and cold electroplating depends on the required durability, surface quality, and environmental exposure of the application.

Cost Analysis and Economic Considerations

Hot-dip nickel plating generally incurs higher initial setup costs due to the need for specialized dipping equipment and temperature control systems, but offers lower operating expenses through faster application and reduced waste. Cold electroplating typically has lower upfront investment and is more versatile for small-scale or complex parts, though it involves higher consumable costs and longer processing times. Economic considerations must account for production volume, part geometry, and desired coating thickness to determine the most cost-effective nickel plating method.

Choosing the Right Nickel Plating Method

Hot-dip nickel plating offers superior corrosion resistance and thicker coating thickness, making it ideal for heavy-duty industrial applications where durability is critical. Cold electroplating provides a thinner, more uniform layer that enhances aesthetic appeal and is suitable for precision components requiring tight tolerances. Evaluating factors like environmental exposure, thickness requirements, and budget constraints ensures the selection of the optimal nickel plating technique.

Hot-dip nickel vs Cold electroplating Infographic

materialdif.com

materialdif.com