Nickel carbonate and nickel oxide differ significantly in their chemical composition and applications; nickel carbonate is a greenish compound primarily used as a precursor in catalysts and ceramics, while nickel oxide is a black powder valued for its use in batteries, pigments, and electrochemical devices. Both compounds serve critical roles in nickel-based technologies, with nickel oxide offering superior thermal stability and electrical conductivity compared to nickel carbonate. Selecting between nickel carbonate and nickel oxide depends on the specific industrial application, chemical reactivity, and desired product performance.

Table of Comparison

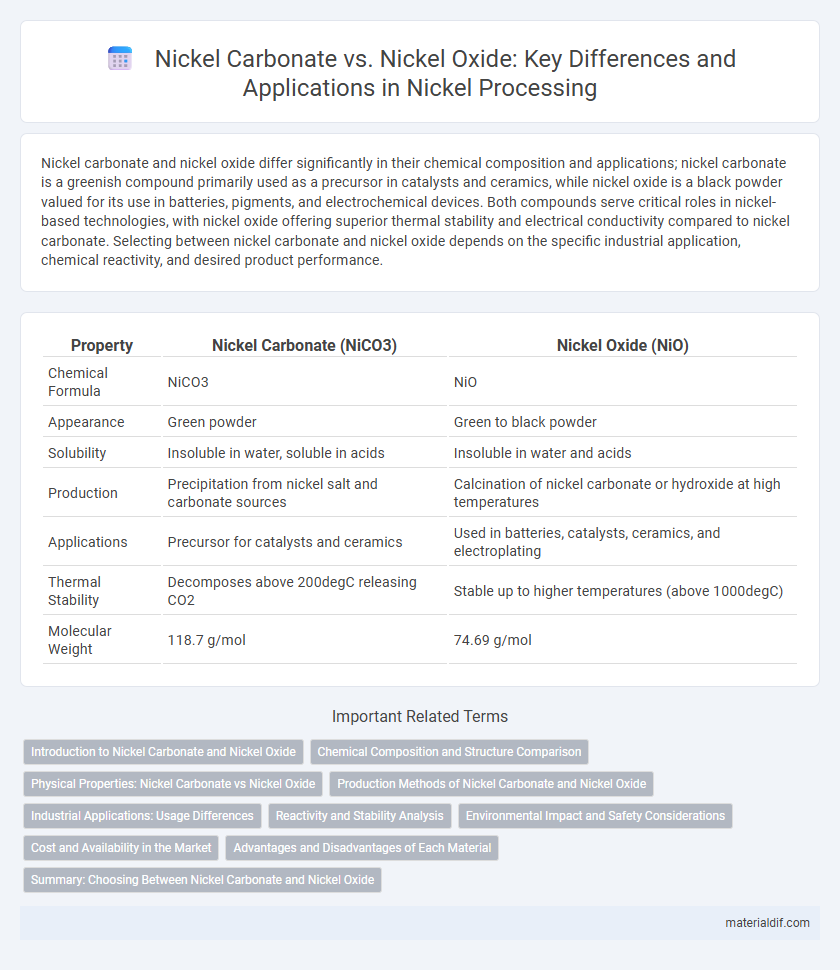

| Property | Nickel Carbonate (NiCO3) | Nickel Oxide (NiO) |

|---|---|---|

| Chemical Formula | NiCO3 | NiO |

| Appearance | Green powder | Green to black powder |

| Solubility | Insoluble in water, soluble in acids | Insoluble in water and acids |

| Production | Precipitation from nickel salt and carbonate sources | Calcination of nickel carbonate or hydroxide at high temperatures |

| Applications | Precursor for catalysts and ceramics | Used in batteries, catalysts, ceramics, and electroplating |

| Thermal Stability | Decomposes above 200degC releasing CO2 | Stable up to higher temperatures (above 1000degC) |

| Molecular Weight | 118.7 g/mol | 74.69 g/mol |

Introduction to Nickel Carbonate and Nickel Oxide

Nickel carbonate (NiCO3) is a green crystalline solid commonly used as a precursor in the production of nickel oxide and catalysts, valued for its ease of decomposition into nickel oxide upon heating. Nickel oxide (NiO) appears as a black or greenish powder and serves as a crucial material in battery electrodes, ceramics, and catalysis due to its stable oxidation state and excellent electrical conductivity. Both compounds play significant roles in the nickel industry, with nickel carbonate primarily acting as a raw material and nickel oxide utilized for its functional properties in various industrial applications.

Chemical Composition and Structure Comparison

Nickel carbonate (NiCO3) contains nickel ions bonded with carbonate groups, forming a crystalline structure characterized by trigonal symmetry. In contrast, nickel oxide (NiO) consists of nickel and oxide ions arranged in a cubic rock salt lattice, exhibiting higher thermal stability and distinct electronic properties. The fundamental difference lies in the presence of carbonate groups in nickel carbonate versus oxide ions in nickel oxide, influencing their reactivity and application in catalysis and battery materials.

Physical Properties: Nickel Carbonate vs Nickel Oxide

Nickel carbonate typically appears as a greenish hydrate solid with a molecular formula of NiCO3*xH2O, featuring low solubility in water and a melting point above 300degC. Nickel oxide, in contrast, is usually a black to greenish-black powder (NiO) with a higher melting point around 1955degC and greater thermal stability. The crystalline structure of nickel oxide is cubic rock salt, while nickel carbonate often forms orthorhombic crystals, impacting their reactivity and suitability for different industrial applications.

Production Methods of Nickel Carbonate and Nickel Oxide

Nickel carbonate is primarily produced through the precipitation method, where nickel sulfate or nickel chloride solutions react with sodium carbonate, yielding a greenish nickel carbonate precipitate. In contrast, nickel oxide is commonly synthesized by thermal decomposition of nickel salts such as nickel nitrate or nickel hydroxide, involving calcination at high temperatures to achieve the oxide form. Production of nickel oxide can also involve direct oxidation of metallic nickel at elevated temperatures in controlled atmospheres.

Industrial Applications: Usage Differences

Nickel carbonate is primarily used as a precursor in the production of nickel catalysts and ceramic pigments due to its high purity and reactivity. Nickel oxide, on the other hand, finds extensive application in battery manufacturing, particularly in nickel-cadmium and nickel-metal hydride batteries, owing to its excellent electrochemical properties. The choice between nickel carbonate and nickel oxide depends on specific industrial requirements like thermal stability and catalytic efficiency.

Reactivity and Stability Analysis

Nickel carbonate exhibits higher reactivity than nickel oxide due to its lower thermal stability and tendency to decompose into nickel oxide and carbon dioxide upon heating. Nickel oxide is thermodynamically more stable, resisting further oxidation under typical environmental conditions and maintaining a consistent crystalline structure. The distinct stability profiles influence their applications, with nickel carbonate preferred as a precursor in catalytic synthesis and nickel oxide favored for high-temperature corrosion-resistant coatings.

Environmental Impact and Safety Considerations

Nickel carbonate and nickel oxide both present environmental challenges, but nickel oxide exhibits greater toxicity and potential for ecological harm due to its higher solubility and bioavailability. Nickel carbonate is less soluble, reducing its immediate impact on aquatic systems, yet both compounds require careful handling to prevent soil and water contamination. Safety protocols emphasize protective equipment and controlled exposure to minimize inhalation risks, with stricter regulations often applied to nickel oxide due to its enhanced reactive properties.

Cost and Availability in the Market

Nickel carbonate is generally more expensive than nickel oxide due to its specialized applications and complex production process, impacting its availability in the market. Nickel oxide enjoys broader availability and lower costs, making it a preferred choice for many industrial uses such as catalysts and batteries. Market demand for nickel oxide remains higher, driven by its versatile applications and easier production scalability.

Advantages and Disadvantages of Each Material

Nickel carbonate offers superior solubility and is often preferred for catalyst preparation and electroplating due to its ease of conversion to nickel oxide under controlled conditions. Nickel oxide provides greater thermal stability and is widely used in battery electrodes and ceramics, but its lower solubility can limit processing flexibility. The choice between nickel carbonate and nickel oxide depends on the specific application requirements, balancing factors such as reactivity, stability, and processing methods.

Summary: Choosing Between Nickel Carbonate and Nickel Oxide

Nickel carbonate and nickel oxide differ primarily in their chemical composition and applications; nickel carbonate is often used as a precursor in ceramics and electroplating, while nickel oxide serves as a catalyst and in battery manufacturing. The choice depends on the required reactivity and thermal stability, with nickel oxide offering higher thermal resistance and nickel carbonate preferred for easier decomposition into oxide forms. Selecting between the two hinges on specific industrial needs, emphasizing the importance of understanding their physicochemical properties for optimal performance.

Nickel Carbonate vs Nickel Oxide Infographic

materialdif.com

materialdif.com