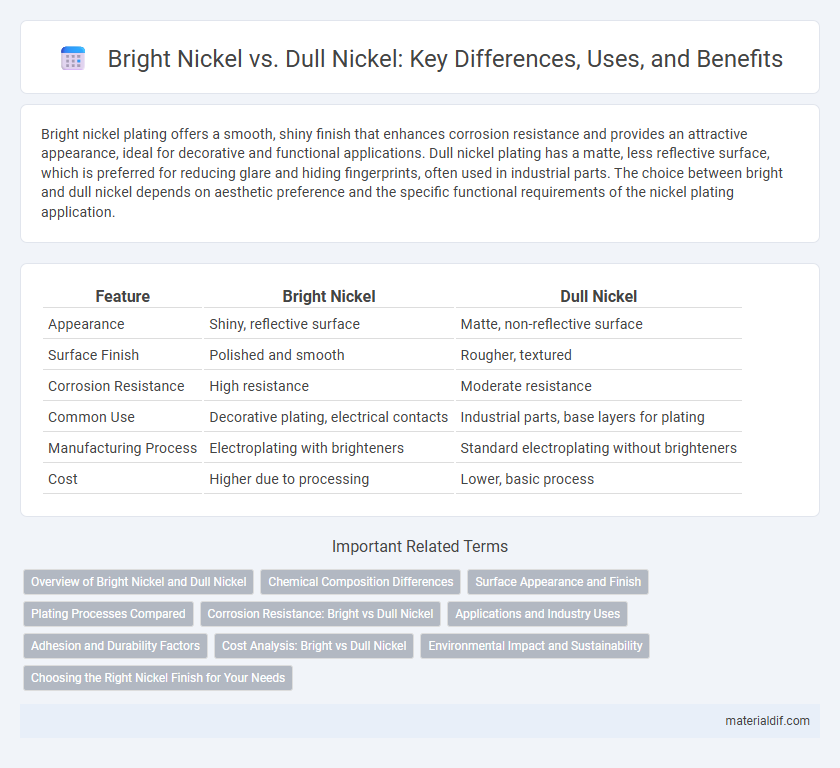

Bright nickel plating offers a smooth, shiny finish that enhances corrosion resistance and provides an attractive appearance, ideal for decorative and functional applications. Dull nickel plating has a matte, less reflective surface, which is preferred for reducing glare and hiding fingerprints, often used in industrial parts. The choice between bright and dull nickel depends on aesthetic preference and the specific functional requirements of the nickel plating application.

Table of Comparison

| Feature | Bright Nickel | Dull Nickel |

|---|---|---|

| Appearance | Shiny, reflective surface | Matte, non-reflective surface |

| Surface Finish | Polished and smooth | Rougher, textured |

| Corrosion Resistance | High resistance | Moderate resistance |

| Common Use | Decorative plating, electrical contacts | Industrial parts, base layers for plating |

| Manufacturing Process | Electroplating with brighteners | Standard electroplating without brighteners |

| Cost | Higher due to processing | Lower, basic process |

Overview of Bright Nickel and Dull Nickel

Bright nickel is a highly polished, lustrous form of nickel commonly used in plating to provide corrosion resistance and aesthetic appeal, characterized by its smooth, reflective surface. Dull nickel, in contrast, has a matte finish with reduced shine, often used where a subdued appearance is preferred or where functional properties like wear resistance outweigh visual considerations. Both types serve crucial roles in industrial applications, with bright nickel favored for decorative purposes and dull nickel for protective coatings in harsh environments.

Chemical Composition Differences

Bright nickel typically contains a higher percentage of nickel and less impurities such as sulfur or phosphorus, resulting in a reflective surface due to its purity. Dull nickel alloys often incorporate increased amounts of iron, carbon, or other metals which contribute to a matte appearance by affecting the microstructure. Variations in chemical composition directly influence corrosion resistance, machinability, and visual finish of nickel coatings.

Surface Appearance and Finish

Bright nickel exhibits a smooth, reflective surface with a polished, shiny finish that enhances corrosion resistance and aesthetic appeal. Dull nickel has a matte, non-reflective surface resulting from a rougher plating process, which provides a more muted appearance with less glare. The choice between bright and dull nickel finishing depends on desired visual impact and functional requirements for durability and protection.

Plating Processes Compared

Bright nickel plating involves a smoother, more reflective surface achieved through the use of specific brighteners and additives in the electroplating bath, resulting in enhanced corrosion resistance and aesthetic appeal. Dull nickel plating produces a matte finish by omitting brighteners, offering superior wear resistance and better adhesion for subsequent coatings. The choice between bright and dull nickel plating depends on the desired surface properties, application requirements, and cost considerations in various industrial sectors.

Corrosion Resistance: Bright vs Dull Nickel

Bright nickel provides superior corrosion resistance compared to dull nickel due to its smoother, more uniform surface which reduces the likelihood of moisture and contaminants adhering to the coating. The electroplating process used for bright nickel creates a dense, compact layer that enhances protection against oxidation and chemical reactions. In contrast, dull nickel's matte finish is more porous and prone to microscopic defects, making it less effective in harsh environments where corrosion resistance is critical.

Applications and Industry Uses

Bright nickel is highly valued in the electronics and automotive industries for its reflective and corrosion-resistant properties, making it ideal for decorative plating and electrical connectors. Dull nickel, with its matte finish and better adhesion qualities, is commonly used in industrial applications such as electroplating base layers and battery electrodes. Both forms contribute significantly to manufacturing processes that require durability and conductivity in sectors like aerospace, electronics, and metal finishing.

Adhesion and Durability Factors

Bright nickel plating exhibits superior adhesion due to its smooth, uniform crystalline structure, which enhances bonding strength to the substrate. Its durability is increased by lower porosity and resistance to corrosion, making it ideal for protective coatings in harsh environments. Dull nickel, while offering better lubricity and wear resistance, typically shows lower adhesion and increased susceptibility to cracking under stress.

Cost Analysis: Bright vs Dull Nickel

Bright nickel plating typically incurs higher costs due to its extensive polishing and cleaning processes, which enhance corrosion resistance and aesthetic appeal. Dull nickel, while more affordable, may require additional maintenance and recoating over time, potentially increasing long-term expenses. Cost analysis reveals that bright nickel is ideal for premium applications where durability and appearance justify the upfront investment.

Environmental Impact and Sustainability

Bright nickel plating uses hexavalent chromium, which poses significant environmental hazards due to its toxicity and challenges in wastewater treatment. Dull nickel plating often employs trivalent chromium or nickel alloys, resulting in lower ecological risks and improved sustainability profiles. Choosing dull nickel reduces hazardous waste generation and aligns better with green manufacturing practices.

Choosing the Right Nickel Finish for Your Needs

Bright nickel offers a highly reflective, shiny surface that enhances corrosion resistance and aesthetic appeal, making it ideal for decorative hardware and plumbing fixtures. Dull nickel, with its matte, non-reflective finish, provides a subtle, vintage look while offering durability and resistance to fingerprints and scratches. Choosing between bright and dull nickel depends on the desired visual effect and application environment, balancing style with practical maintenance requirements.

Bright nickel vs dull nickel Infographic

materialdif.com

materialdif.com