Nickel carbonate and nickel sulfate are both important nickel compounds used in various industrial applications, but they differ significantly in their chemical properties and uses. Nickel carbonate is commonly used as a precursor in the production of nickel catalysts and ceramics, prized for its stability and low solubility in water. In contrast, nickel sulfate is highly soluble and widely employed in electroplating, battery manufacturing, and as a source of nickel ions in chemical reactions.

Table of Comparison

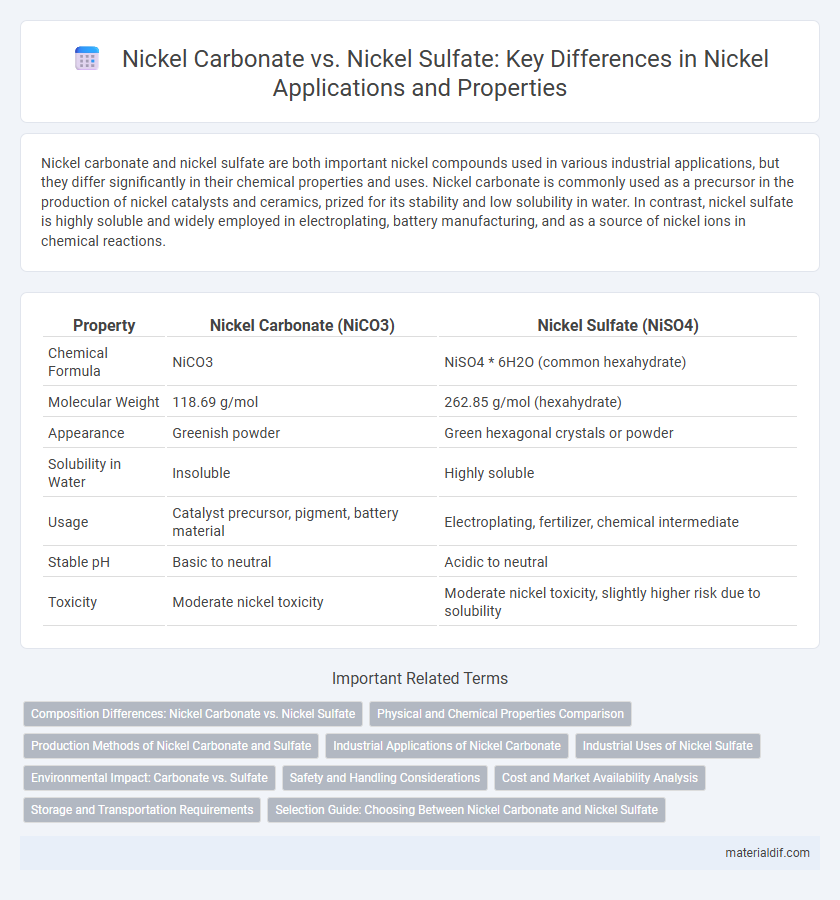

| Property | Nickel Carbonate (NiCO3) | Nickel Sulfate (NiSO4) |

|---|---|---|

| Chemical Formula | NiCO3 | NiSO4 * 6H2O (common hexahydrate) |

| Molecular Weight | 118.69 g/mol | 262.85 g/mol (hexahydrate) |

| Appearance | Greenish powder | Green hexagonal crystals or powder |

| Solubility in Water | Insoluble | Highly soluble |

| Usage | Catalyst precursor, pigment, battery material | Electroplating, fertilizer, chemical intermediate |

| Stable pH | Basic to neutral | Acidic to neutral |

| Toxicity | Moderate nickel toxicity | Moderate nickel toxicity, slightly higher risk due to solubility |

Composition Differences: Nickel Carbonate vs. Nickel Sulfate

Nickel carbonate (NiCO3) consists of nickel ions bound to carbonate groups, whereas nickel sulfate (NiSO4) combines nickel ions with sulfate anions, leading to distinct chemical and physical properties. The presence of sulfate in nickel sulfate enhances its solubility and reactivity in aqueous solutions compared to the relatively insoluble nickel carbonate. These compositional variations influence their applications in electroplating, ceramics, and catalysts, where solubility and ion availability are critical factors.

Physical and Chemical Properties Comparison

Nickel carbonate (NiCO3) appears as a pale green powder, exhibiting low solubility in water and decomposes upon heating to release carbon dioxide, whereas nickel sulfate (NiSO4) is a blue to green crystalline solid with high water solubility and tends to form stable hydrates. Chemically, nickel carbonate acts as a basic salt, reacting with acids to produce nickel sulfate and carbon dioxide, while nickel sulfate is acidic and often used in electroplating due to its ionic nature and conductivity in aqueous solutions. Both compounds have distinct thermal stability profiles and solubility characteristics that influence their applications in catalysis, battery production, and electrochemical processes.

Production Methods of Nickel Carbonate and Sulfate

Nickel carbonate is typically produced through the reaction of nickel salts, such as nickel sulfate or nickel chloride, with sodium carbonate or sodium bicarbonate, resulting in the precipitation of nickel carbonate. Nickel sulfate is primarily synthesized by dissolving nickel oxide or nickel hydroxide in sulfuric acid, followed by crystallization to obtain nickel sulfate crystals. Both compounds serve as important intermediates in nickel refining and electroplating industries, with production methods tailored to their specific chemical properties and end-use requirements.

Industrial Applications of Nickel Carbonate

Nickel carbonate is widely used in the production of nickel catalysts and as a precursor for nickel oxide in ceramics and batteries, offering excellent thermal stability and purity. Unlike nickel sulfate, which is primarily employed in electroplating and metal finishing industries, nickel carbonate finds industrial applications in manufacturing chemical reagents, pigments, and specialty alloys. Its role in producing high-performance catalysts for hydrogenation and chemical processing highlights its significance in industrial chemistry.

Industrial Uses of Nickel Sulfate

Nickel sulfate is extensively used in electroplating and battery manufacturing, particularly for producing nickel-cadmium and lithium-ion batteries, due to its high solubility and purity. Industrial processes favor nickel sulfate over nickel carbonate because it facilitates more consistent electrodeposition and easier control of nickel ion concentration. The use of nickel sulfate enhances corrosion resistance and conductivity in metal coatings, making it a critical compound in the electronics and automotive industries.

Environmental Impact: Carbonate vs. Sulfate

Nickel carbonate generates fewer soluble nickel compounds, reducing the risk of water contamination compared to nickel sulfate, which is highly soluble and more likely to leach into aquatic environments. The lower solubility of nickel carbonate contributes to decreased bioavailability and toxicity to aquatic organisms, making it a more environmentally stable option. Nickel sulfate's high solubility warrants stricter waste management to prevent soil and groundwater pollution.

Safety and Handling Considerations

Nickel carbonate and nickel sulfate both require careful handling due to their toxic and potentially carcinogenic properties, with nickel sulfate generally being more soluble and thus posing a higher risk of skin and respiratory exposure. Proper personal protective equipment (PPE) including gloves, goggles, and respiratory protection is essential when handling either compound to prevent contact and inhalation. Storage in well-ventilated, cool, and dry areas away from incompatible substances is critical to minimize chemical hazards and environmental impact.

Cost and Market Availability Analysis

Nickel carbonate generally costs more than nickel sulfate due to its more complex production process and lower demand in industrial applications. Nickel sulfate dominates the market with higher availability, supported by extensive use in battery manufacturing and electroplating industries. Price volatility in nickel sulfate is influenced by fluctuations in nickel metal prices and demand from the electric vehicle sector.

Storage and Transportation Requirements

Nickel carbonate requires storage in tightly sealed containers to prevent moisture absorption and degradation, while nickel sulfate demands corrosion-resistant drums to handle its hygroscopic and acidic nature. Both compounds should be transported in compliance with hazardous materials regulations, ensuring secure containment to avoid spills and environmental contamination. Proper ventilation and temperature control are critical during transit to maintain chemical stability and safety.

Selection Guide: Choosing Between Nickel Carbonate and Nickel Sulfate

Nickel carbonate and nickel sulfate differ primarily in solubility and application, with nickel sulfate offering higher solubility suitable for electroplating and chemical synthesis, while nickel carbonate is preferred for its stability in pigment production and as a precursor in catalyst manufacturing. The selection depends on factors such as desired nickel ion concentration, process efficiency, and specific industrial requirements, where nickel sulfate supports faster reaction rates and better uniformity. Cost, environmental considerations, and handling safety also influence the decision, as nickel carbonate tends to be less hazardous and more cost-effective for bulk uses.

Nickel carbonate vs nickel sulfate Infographic

materialdif.com

materialdif.com