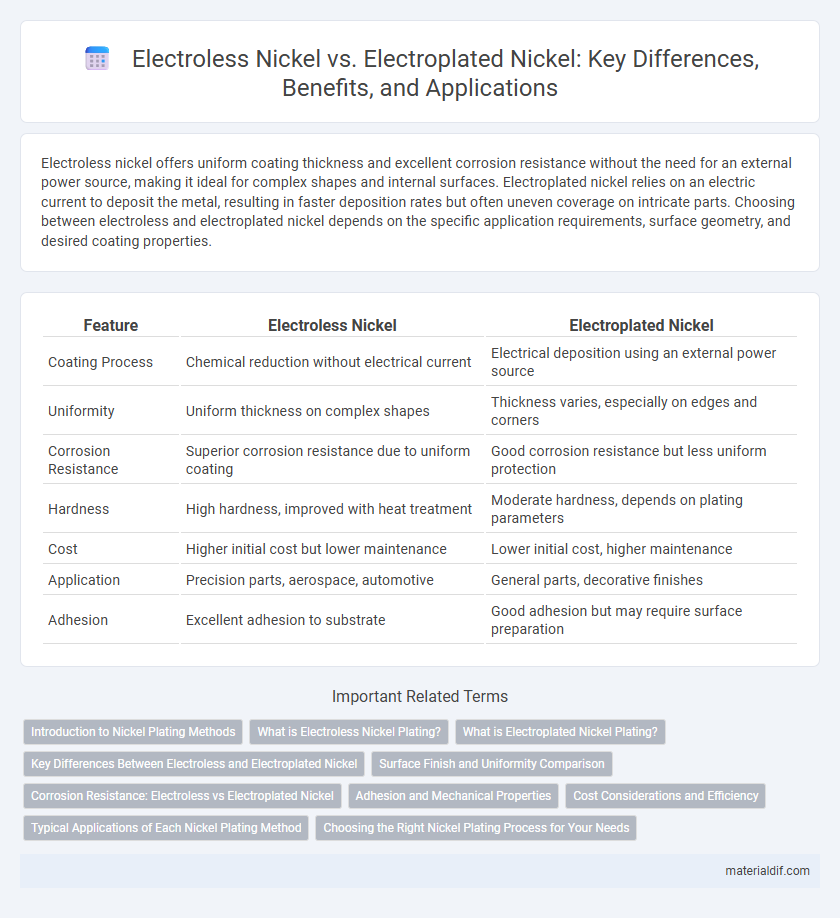

Electroless nickel offers uniform coating thickness and excellent corrosion resistance without the need for an external power source, making it ideal for complex shapes and internal surfaces. Electroplated nickel relies on an electric current to deposit the metal, resulting in faster deposition rates but often uneven coverage on intricate parts. Choosing between electroless and electroplated nickel depends on the specific application requirements, surface geometry, and desired coating properties.

Table of Comparison

| Feature | Electroless Nickel | Electroplated Nickel |

|---|---|---|

| Coating Process | Chemical reduction without electrical current | Electrical deposition using an external power source |

| Uniformity | Uniform thickness on complex shapes | Thickness varies, especially on edges and corners |

| Corrosion Resistance | Superior corrosion resistance due to uniform coating | Good corrosion resistance but less uniform protection |

| Hardness | High hardness, improved with heat treatment | Moderate hardness, depends on plating parameters |

| Cost | Higher initial cost but lower maintenance | Lower initial cost, higher maintenance |

| Application | Precision parts, aerospace, automotive | General parts, decorative finishes |

| Adhesion | Excellent adhesion to substrate | Good adhesion but may require surface preparation |

Introduction to Nickel Plating Methods

Electroless nickel plating uses a chemical reduction process to deposit a uniform nickel-phosphorus or nickel-boron alloy coating without electrical current, providing excellent corrosion resistance and wear durability on complex shapes. Electroplated nickel plating relies on an electric current to reduce nickel ions onto a conductive substrate, enabling precise thickness control and enhanced adhesion on flat or conductive surfaces. Both techniques serve critical roles in industries like aerospace, electronics, and automotive, where surface hardness, corrosion protection, and aesthetics are essential.

What is Electroless Nickel Plating?

Electroless nickel plating is a chemical process that deposits a uniform layer of nickel-phosphorus or nickel-boron alloy on a substrate without using electrical current. This method ensures even coating thickness on complex geometries and interior surfaces, enhancing corrosion resistance and wear properties more consistently than electroplated nickel. The autocatalytic reaction provides superior adhesion and hardness, making electroless nickel ideal for precision components in aerospace, automotive, and electronics industries.

What is Electroplated Nickel Plating?

Electroplated nickel plating is a process that uses an electrical current to deposit a layer of nickel onto a metal surface, providing enhanced corrosion resistance, wear resistance, and aesthetic appeal. This technique allows precise control over coating thickness and uniformity, making it ideal for components in automotive, aerospace, and electronics industries. Electroplated nickel offers superior adhesion and is often used where durability and surface hardness are critical.

Key Differences Between Electroless and Electroplated Nickel

Electroless nickel plating deposits a uniform, autocatalytic nickel-phosphorus or nickel-boron alloy coating without requiring an external electrical current, resulting in consistent thickness on complex geometries. Electroplated nickel relies on an electric current to reduce nickel ions from a plating bath onto the substrate, which can lead to uneven coverage on intricate surfaces. Key differences include electroless nickel's superior wear resistance and corrosion protection due to its chemical deposition process, compared to electroplated nickel's variable thickness and potential for burning or pitting during plating.

Surface Finish and Uniformity Comparison

Electroless nickel plating offers a highly uniform surface finish due to its autocatalytic chemical deposition process, ensuring even coating on complex geometries without the need for electrical current. In contrast, electroplated nickel relies on an electric current that can cause uneven thickness, especially on intricate shapes or edges, leading to less consistent uniformity. Electroless nickel coatings provide superior smoothness and corrosion resistance, making them ideal for applications demanding precise dimensional control and high-quality surface finishes.

Corrosion Resistance: Electroless vs Electroplated Nickel

Electroless nickel plating offers superior corrosion resistance due to its uniform, non-porous coating and consistent thickness, which prevents localized corrosion and enhances protection in harsh environments. Electroplated nickel, applied through an electric current, often results in uneven layers that can create weak points susceptible to corrosion, especially under mechanical stress or exposure to corrosive agents. The autocatalytic nature of electroless nickel also allows for better adhesion and resistance to pitting and wear compared to conventional electroplated nickel finishes.

Adhesion and Mechanical Properties

Electroless nickel plating offers superior adhesion due to its uniform, non-porous coating that chemically bonds to substrates, enhancing wear resistance and hardness without the need for electrical current. Electroplated nickel typically exhibits variable thickness and potential adhesion issues caused by uneven deposition, which can result in reduced mechanical durability under stress. Mechanical properties such as hardness and corrosion resistance are generally more consistent in electroless nickel coatings, making them preferable for critical applications demanding uniform performance.

Cost Considerations and Efficiency

Electroless nickel plating provides uniform coating thickness and superior corrosion resistance, often leading to reduced maintenance costs despite higher initial expenses. Electroplated nickel typically offers lower upfront costs and faster processing times but may require additional surface preparation and post-treatment to achieve comparable durability. Efficiency in production depends on specific application needs, balancing material usage, labor costs, and long-term performance benefits.

Typical Applications of Each Nickel Plating Method

Electroless nickel plating is commonly used in applications requiring uniform coating thickness, excellent corrosion resistance, and wear resistance, such as aerospace components, automotive engine parts, and electronic connectors. Electroplated nickel is typically applied where high thickness and decorative finishes are important, including hardware, household fixtures, and automotive trim. Both methods enhance surface hardness and corrosion protection but cater to different performance and aesthetic needs in industrial and commercial uses.

Choosing the Right Nickel Plating Process for Your Needs

Electroless nickel plating offers uniform coating thickness on complex geometries and excellent corrosion resistance without the need for electrical power, making it ideal for intricate parts and wear-resistant applications. Electroplated nickel provides faster deposition rates and is cost-effective for simpler shapes with high production volumes, delivering good conductivity and decorative finishes. Selecting the right nickel plating process depends on factors such as part complexity, required coating uniformity, corrosion or wear resistance, budget constraints, and production scale.

Electroless Nickel vs Electroplated Nickel Infographic

materialdif.com

materialdif.com