Wrought nickel offers superior strength and ductility due to its forged and mechanically worked structure, making it ideal for applications requiring high durability and precise shaping. Cast nickel, formed by pouring molten metal into molds, provides excellent corrosion resistance and complex shapes but tends to have lower mechanical strength compared to wrought nickel. Selecting between wrought and cast nickel depends on the specific needs for structural integrity versus intricate design and corrosion performance.

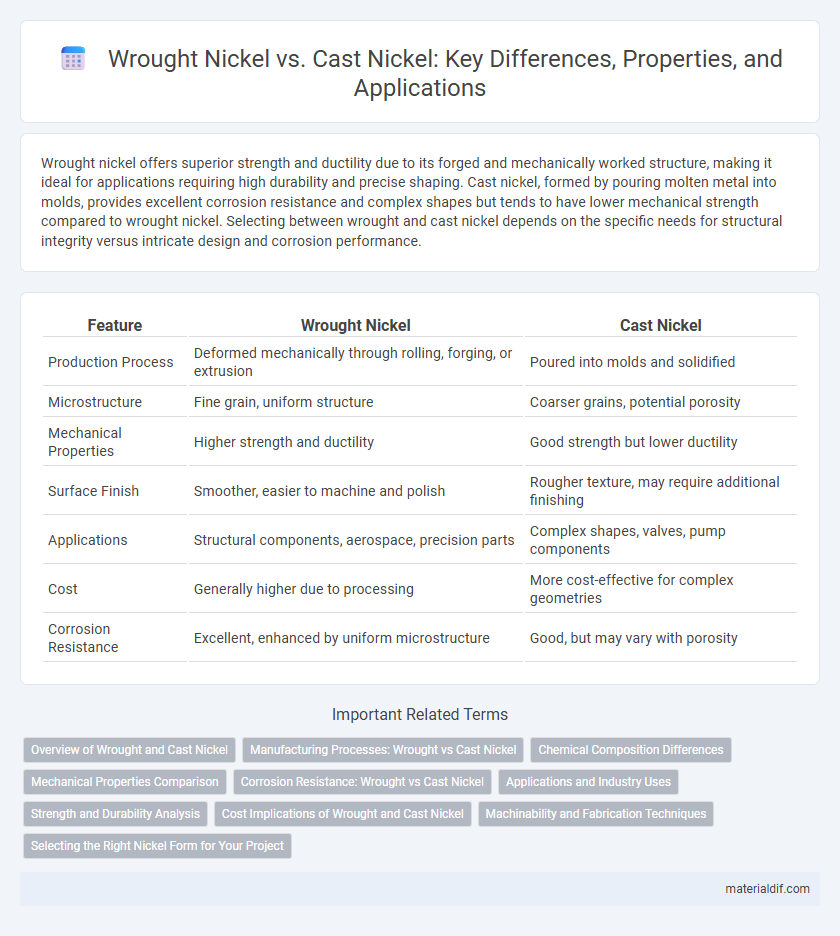

Table of Comparison

| Feature | Wrought Nickel | Cast Nickel |

|---|---|---|

| Production Process | Deformed mechanically through rolling, forging, or extrusion | Poured into molds and solidified |

| Microstructure | Fine grain, uniform structure | Coarser grains, potential porosity |

| Mechanical Properties | Higher strength and ductility | Good strength but lower ductility |

| Surface Finish | Smoother, easier to machine and polish | Rougher texture, may require additional finishing |

| Applications | Structural components, aerospace, precision parts | Complex shapes, valves, pump components |

| Cost | Generally higher due to processing | More cost-effective for complex geometries |

| Corrosion Resistance | Excellent, enhanced by uniform microstructure | Good, but may vary with porosity |

Overview of Wrought and Cast Nickel

Wrought nickel is produced through mechanical working processes such as rolling, forging, and extrusion, resulting in improved strength, toughness, and uniform grain structure. Cast nickel is formed by melting and pouring the metal into molds, allowing for complex shapes and thicker sections but generally exhibiting coarser microstructure and lower mechanical properties. Both forms are essential in industrial applications, with wrought nickel favored for structural components and cast nickel used in intricate parts requiring high corrosion resistance.

Manufacturing Processes: Wrought vs Cast Nickel

Wrought nickel is produced through mechanical processes such as rolling, forging, or extrusion, which enhance its strength and toughness by aligning the metal's grain structure. Cast nickel, formed by pouring molten metal into molds and allowing it to solidify, often has a coarser microstructure that can result in different mechanical properties like improved castability but lower ductility. The choice between wrought and cast nickel depends heavily on the application's requirements for mechanical performance and manufacturing complexity.

Chemical Composition Differences

Wrought nickel typically contains a higher purity of nickel, often above 99%, with controlled amounts of elements like iron, carbon, and manganese to enhance mechanical properties. Cast nickel alloys may include additional alloying elements such as chromium, molybdenum, copper, or silicon to improve castability, corrosion resistance, and strength in complex shapes. These variations in chemical composition result in wrought nickel offering superior ductility and toughness, while cast nickel alloys provide enhanced wear resistance and performance in harsh environments.

Mechanical Properties Comparison

Wrought nickel exhibits superior mechanical properties compared to cast nickel, including higher tensile strength, improved ductility, and enhanced fatigue resistance due to its refined grain structure from hot or cold working processes. Cast nickel, while easier to shape into complex forms, typically possesses lower toughness and increased brittleness resulting from solidification defects and coarser microstructures. The mechanical performance of wrought nickel makes it preferable for applications requiring high durability and resistance to mechanical stress.

Corrosion Resistance: Wrought vs Cast Nickel

Wrought nickel exhibits superior corrosion resistance compared to cast nickel due to its refined grain structure and fewer impurities, which reduce susceptibility to pitting and stress corrosion cracking. Cast nickel, while still corrosion-resistant, may contain microsegregations and inclusions that can act as initiation sites for corrosion, especially in aggressive environments. This makes wrought nickel the preferred choice in highly corrosive applications such as chemical processing and marine industries.

Applications and Industry Uses

Wrought nickel offers superior mechanical strength and corrosion resistance, making it ideal for aerospace components, marine equipment, and chemical processing industries. Cast nickel is preferred in applications requiring complex shapes and high wear resistance, such as turbine blades, engine parts, and valves in power generation. Both forms support critical roles in manufacturing sectors demanding durability and high-performance materials.

Strength and Durability Analysis

Wrought nickel exhibits superior strength and durability compared to cast nickel due to its refined grain structure achieved through mechanical deformation processes like rolling or forging. Cast nickel tends to have a coarser microstructure with potential porosity, making it more susceptible to brittleness and lower impact resistance. Consequently, wrought nickel is preferred in applications demanding higher mechanical performance and enhanced fatigue resistance.

Cost Implications of Wrought and Cast Nickel

Wrought nickel generally incurs higher production costs due to extensive mechanical working processes, resulting in superior strength and durability compared to cast nickel. Cast nickel, formed through melting and pouring into molds, offers cost-effective manufacturing suitable for complex shapes but may have inferior mechanical properties and higher risk of defects. Cost implications favor wrought nickel for applications requiring long-term performance and reliability, while cast nickel provides economical solutions for less demanding uses.

Machinability and Fabrication Techniques

Wrought nickel exhibits superior machinability compared to cast nickel due to its refined grain structure and uniform composition, allowing for precise cutting and shaping in manufacturing processes. Fabrication techniques for wrought nickel typically involve rolling, forging, and extrusion, which enhance mechanical properties and surface finish, while cast nickel, produced by pouring molten metal into molds, often requires extensive machining to achieve desired tolerances. The choice between wrought and cast nickel depends on specific application requirements, including strength, corrosion resistance, and complexity of the final component geometry.

Selecting the Right Nickel Form for Your Project

Wrought nickel offers superior mechanical properties, including higher tensile strength and better ductility, making it ideal for applications requiring precise shaping and durability. Cast nickel provides excellent corrosion resistance and is suitable for complex geometries or large-scale production where dimensional stability is critical. Selecting the right nickel form depends on project requirements such as mechanical stress, environmental exposure, and manufacturing complexity.

Wrought Nickel vs Cast Nickel Infographic

materialdif.com

materialdif.com