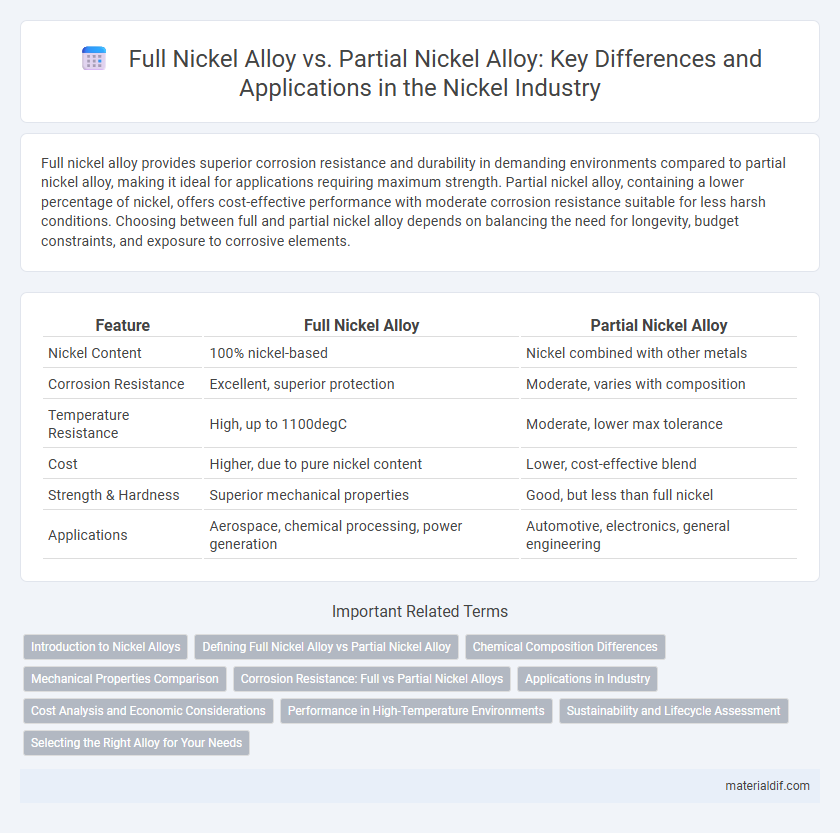

Full nickel alloy provides superior corrosion resistance and durability in demanding environments compared to partial nickel alloy, making it ideal for applications requiring maximum strength. Partial nickel alloy, containing a lower percentage of nickel, offers cost-effective performance with moderate corrosion resistance suitable for less harsh conditions. Choosing between full and partial nickel alloy depends on balancing the need for longevity, budget constraints, and exposure to corrosive elements.

Table of Comparison

| Feature | Full Nickel Alloy | Partial Nickel Alloy |

|---|---|---|

| Nickel Content | 100% nickel-based | Nickel combined with other metals |

| Corrosion Resistance | Excellent, superior protection | Moderate, varies with composition |

| Temperature Resistance | High, up to 1100degC | Moderate, lower max tolerance |

| Cost | Higher, due to pure nickel content | Lower, cost-effective blend |

| Strength & Hardness | Superior mechanical properties | Good, but less than full nickel |

| Applications | Aerospace, chemical processing, power generation | Automotive, electronics, general engineering |

Introduction to Nickel Alloys

Full nickel alloys exhibit superior corrosion resistance, high-temperature strength, and excellent mechanical properties due to their nearly pure nickel content, making them ideal for extreme environments. Partial nickel alloys, containing a blend of nickel with other metals like chromium, iron, or copper, offer tailored properties such as enhanced toughness, machinability, and cost-effectiveness for diverse industrial applications. The choice between full and partial nickel alloys depends on specific performance requirements, balancing factors like thermal stability, corrosion resistance, and manufacturing considerations.

Defining Full Nickel Alloy vs Partial Nickel Alloy

Full nickel alloy is composed entirely or predominantly of nickel, typically exceeding 99% purity, offering superior corrosion resistance, high-temperature stability, and excellent mechanical strength. Partial nickel alloy contains a significant percentage of nickel combined with other metals such as iron, copper, or chromium, creating a material that balances cost with enhanced properties like improved hardness or ductility. The choice between full nickel alloy and partial nickel alloy depends on specific application requirements, including environmental conditions and performance demands.

Chemical Composition Differences

Full nickel alloys typically consist of a high percentage of nickel, often exceeding 50%, combined with elements like chromium, iron, and molybdenum to enhance corrosion resistance and mechanical strength. Partial nickel alloys contain a lower nickel content, generally between 10% and 40%, and incorporate other metals such as copper, cobalt, or manganese to tailor properties for specific industrial applications. The chemical composition differences directly influence alloy characteristics, including thermal stability, oxidation resistance, and magnetic properties.

Mechanical Properties Comparison

Full nickel alloys exhibit superior mechanical properties such as higher tensile strength, enhanced fatigue resistance, and better corrosion endurance compared to partial nickel alloys, making them ideal for high-stress applications. Partial nickel alloys, containing a lower nickel content, typically show reduced hardness and lower creep resistance but can offer improved machinability and cost efficiency. The selection between full and partial nickel alloys depends on balancing mechanical performance requirements with economic considerations in engineering design.

Corrosion Resistance: Full vs Partial Nickel Alloys

Full nickel alloys exhibit superior corrosion resistance due to their higher nickel content, which enhances resistance to acids, alkalis, and oxidative environments. Partial nickel alloys contain less nickel and often include other metals, resulting in reduced protection against aggressive chemicals and increased susceptibility to pitting and galvanic corrosion. In marine and chemical processing applications, full nickel alloys provide more reliable long-term durability compared to partial nickel alloys.

Applications in Industry

Full nickel alloys exhibit superior corrosion resistance, high temperature stability, and excellent mechanical strength, making them ideal for aerospace, chemical processing, and marine applications where extreme conditions prevail. Partial nickel alloys, often combined with elements like iron or copper, provide cost-effective solutions with balanced durability and conductivity, frequently utilized in electrical components, automotive parts, and consumer goods. The choice between full and partial nickel alloys depends on the specific industrial demands for performance, cost-efficiency, and environmental exposure.

Cost Analysis and Economic Considerations

Full nickel alloys typically incur higher production costs due to the extensive use of pure nickel, leading to increased raw material expenses and energy consumption during processing. Partial nickel alloys reduce these costs by substituting portions of nickel with less expensive metals such as iron or copper, offering significant savings while maintaining adequate corrosion resistance and mechanical properties. Economic considerations favor partial nickel alloys in budget-sensitive applications where moderate performance criteria are acceptable, whereas full nickel alloys justify their premium costs in high-performance environments requiring superior corrosion resistance and durability.

Performance in High-Temperature Environments

Full nickel alloys exhibit superior performance in high-temperature environments due to their excellent oxidation resistance and thermal stability, maintaining mechanical strength at elevated temperatures above 1000degF (538degC). Partial nickel alloys, containing lower nickel content, may display reduced corrosion resistance and are more prone to thermal degradation under prolonged heat exposure. Selecting full nickel alloys is critical in applications requiring sustained strength and resistance to scaling in harsh, high-temperature industrial processes.

Sustainability and Lifecycle Assessment

Full nickel alloys offer superior corrosion resistance and durability, resulting in extended product lifecycles and reduced need for frequent replacements, which enhances sustainability. Partial nickel alloys often combine nickel with other metals to lower cost and weight but may compromise longevity and recyclability, potentially increasing environmental impact over time. Lifecycle assessment reveals that full nickel alloys generally deliver better eco-efficiency due to their robustness and higher recycling rates, supporting circular economy goals more effectively.

Selecting the Right Alloy for Your Needs

Full nickel alloys offer superior corrosion resistance and high-temperature strength, making them ideal for demanding industrial applications such as chemical processing and aerospace parts. Partial nickel alloys provide cost-effective alternatives with adequate durability for less extreme environments, suitable for automotive components and general manufacturing. Selecting the right alloy depends on application-specific requirements including thermal stability, mechanical stress, and exposure to corrosive elements.

Full nickel alloy vs Partial nickel alloy Infographic

materialdif.com

materialdif.com