Anodizing and passivating are distinct surface treatment processes used to enhance the corrosion resistance of nickel products. Anodizing creates a thick, durable oxide layer through an electrochemical process, improving hardness and wear resistance, while passivating forms a thin, protective oxide film that prevents surface oxidation without altering the metal's thickness. Choosing between anodizing and passivating depends on the desired properties, with anodizing suited for enhanced durability and passivating ideal for maintaining surface integrity in less abrasive environments.

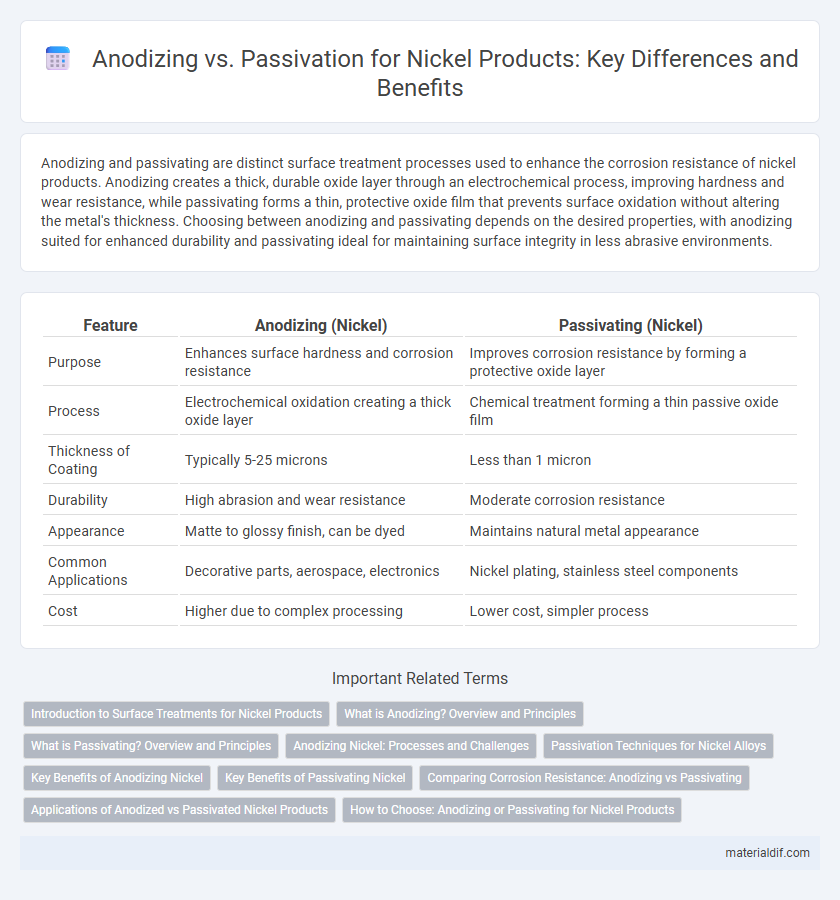

Table of Comparison

| Feature | Anodizing (Nickel) | Passivating (Nickel) |

|---|---|---|

| Purpose | Enhances surface hardness and corrosion resistance | Improves corrosion resistance by forming a protective oxide layer |

| Process | Electrochemical oxidation creating a thick oxide layer | Chemical treatment forming a thin passive oxide film |

| Thickness of Coating | Typically 5-25 microns | Less than 1 micron |

| Durability | High abrasion and wear resistance | Moderate corrosion resistance |

| Appearance | Matte to glossy finish, can be dyed | Maintains natural metal appearance |

| Common Applications | Decorative parts, aerospace, electronics | Nickel plating, stainless steel components |

| Cost | Higher due to complex processing | Lower cost, simpler process |

Introduction to Surface Treatments for Nickel Products

Anodizing and passivating are essential surface treatments for nickel products, enhancing corrosion resistance and durability. Anodizing creates a thick, protective oxide layer through electrochemical processes, while passivating involves a chemical treatment that forms a thin, inert film to prevent oxidation. Both methods optimize nickel's performance in harsh environments, extending the lifespan of components in aerospace, automotive, and electronics industries.

What is Anodizing? Overview and Principles

Anodizing is an electrochemical process that enhances the natural oxide layer on nickel products, increasing corrosion resistance and surface hardness. This technique involves immersing the nickel item in an acid electrolyte bath and applying an electrical current to form a durable oxide coating. The resulting anodic film is porous and can be dyed or sealed for improved aesthetics and protection.

What is Passivating? Overview and Principles

Passivating nickel involves creating a thin, protective oxide layer on the metal surface to enhance corrosion resistance and reduce reactivity. The process typically uses chemical treatments, such as nitric acid solutions, which remove free iron and contaminants, promoting the formation of a stable, inert film. This passive layer prevents oxidation and extends the longevity of nickel products in various industrial applications.

Anodizing Nickel: Processes and Challenges

Anodizing nickel involves electrochemically oxidizing the metal surface to create a protective nickel oxide layer that enhances corrosion resistance, hardness, and wear properties. The process requires precise control of parameters such as electrolyte composition, temperature, and current density to achieve uniform coating thickness and optimal surface characteristics. Challenges include managing the formation of porous oxide layers, preventing hydrogen embrittlement, and ensuring adhesion without compromising the mechanical properties of nickel components.

Passivation Techniques for Nickel Alloys

Passivation techniques for nickel alloys primarily involve creating a thin, protective oxide layer that enhances corrosion resistance by minimizing the metal's reactive surface. Unlike anodizing, which adds a thicker oxide coating through an electrochemical process, passivation relies on chemical treatments such as nitric acid or citric acid baths to remove free iron and promote stable oxide formation. These methods improve the longevity and durability of nickel alloy components used in harsh environments like chemical processing and marine applications.

Key Benefits of Anodizing Nickel

Anodizing nickel enhances corrosion resistance by creating a durable oxide layer that protects the metal surface from environmental degradation. This process improves wear resistance and extends the lifespan of nickel products, making them suitable for demanding industrial applications. The anodic layer also provides an excellent base for paint and other coatings, improving adhesion and aesthetic appeal.

Key Benefits of Passivating Nickel

Passivating nickel enhances corrosion resistance by forming a stable, protective oxide layer that prevents oxidation and surface degradation. This process improves the durability and longevity of nickel products in harsh environments without altering their appearance or dimensions. Passivation is crucial for maintaining the metal's purity and ensuring consistent performance in industrial applications such as electronics, automotive, and aerospace components.

Comparing Corrosion Resistance: Anodizing vs Passivating

Anodizing nickel enhances corrosion resistance by creating a hard, oxide layer that protects the surface from environmental factors, making it ideal for harsh conditions. Passivating nickel involves treating the surface to remove contaminants and promote a thin, protective oxide film, which improves corrosion resistance but is generally less durable than anodized coatings. Anodized nickel typically offers superior long-term corrosion protection compared to passivated nickel, especially in aggressive or marine environments.

Applications of Anodized vs Passivated Nickel Products

Anodized nickel products offer superior corrosion resistance and enhanced surface hardness, making them ideal for industries requiring durable coatings such as aerospace, automotive, and electronics. Passivated nickel products excel in chemical resistance and oxidation prevention, widely used in medical devices, food processing equipment, and chemical processing plants. Selecting anodizing or passivating depends on the application's demand for wear resistance versus corrosion control in harsh environments.

How to Choose: Anodizing or Passivating for Nickel Products

Choosing between anodizing and passivating for nickel products depends on the desired level of corrosion resistance and surface finish. Anodizing enhances the oxide layer on nickel alloys, providing superior protection in harsh environments and improving hardness, while passivating creates a thin, protective oxide film to prevent rust and maintain the metal's natural luster. Evaluate the operating conditions, such as exposure to chemicals or moisture, and the importance of surface aesthetics to determine whether anodizing's durability or passivating's subtle protection best suits your nickel application.

Anodizing vs Passivating (Nickel Products) Infographic

materialdif.com

materialdif.com