A nickel coin is composed primarily of a copper-nickel alloy, giving it durability and resistance to corrosion, while a nickel-plated coin features a base metal core coated with a thin layer of nickel for a shiny appearance. Nickel coins tend to have a more consistent weight and composition, ensuring reliable use in vending machines and coin-operated devices. The plating on nickel-plated coins can wear off over time, exposing the underlying metal and reducing their visual appeal and resistance to tarnishing.

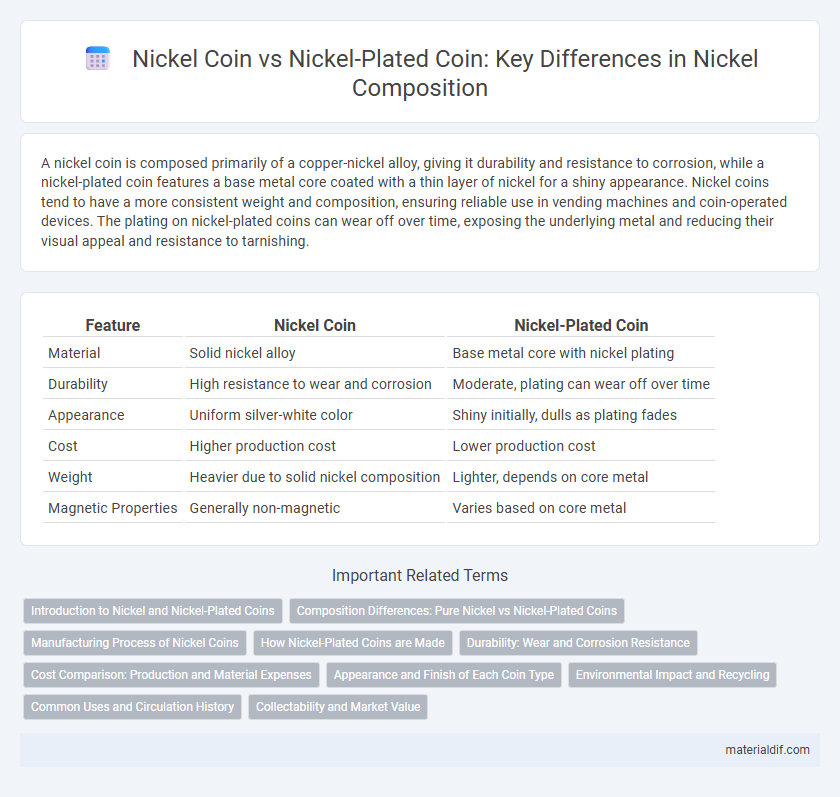

Table of Comparison

| Feature | Nickel Coin | Nickel-Plated Coin |

|---|---|---|

| Material | Solid nickel alloy | Base metal core with nickel plating |

| Durability | High resistance to wear and corrosion | Moderate, plating can wear off over time |

| Appearance | Uniform silver-white color | Shiny initially, dulls as plating fades |

| Cost | Higher production cost | Lower production cost |

| Weight | Heavier due to solid nickel composition | Lighter, depends on core metal |

| Magnetic Properties | Generally non-magnetic | Varies based on core metal |

Introduction to Nickel and Nickel-Plated Coins

Nickel is a durable, corrosion-resistant metal primarily used in alloy production and coinage. Nickel coins consist mostly of a nickel alloy, providing solidity and value, while nickel-plated coins feature a base metal core coated with a thin layer of nickel for enhanced appearance and wear resistance. These differences impact the coins' longevity, cost, and material composition in circulation and collecting.

Composition Differences: Pure Nickel vs Nickel-Plated Coins

Nickel coins are typically composed of 75% copper and 25% nickel, creating a durable alloy that resists corrosion and wear. In contrast, nickel-plated coins feature a core made from a less expensive metal such as copper or zinc, coated with a thin layer of nickel to achieve a similar appearance. The primary distinction lies in the composition: pure nickel coins offer consistent metal content throughout, while nickel-plated coins rely on the plating for their nickel surface, affecting factors like weight, magnetic properties, and corrosion resistance.

Manufacturing Process of Nickel Coins

Nickel coins are manufactured using a solid alloy primarily composed of nickel along with copper, which is melted and pressed into blanks before being stamped with intricate designs through high-pressure dies. In contrast, nickel-plated coins consist of a core metal such as copper or zinc, which undergoes electroplating to deposit a thin layer of nickel on the surface, enhancing corrosion resistance and appearance without the cost of solid nickel. The manufacturing process of solid nickel coins requires more raw nickel material and precise temperature control during alloying, whereas nickel plating involves additional steps of surface preparation and electrochemical deposition.

How Nickel-Plated Coins are Made

Nickel-plated coins are produced by applying a thin layer of nickel onto a base metal core, often made of copper or zinc, through an electroplating process. This method ensures durability and corrosion resistance while reducing costs compared to solid nickel coins. The electroplating process involves submerging the base metal coin into a nickel salt solution and passing an electric current to deposit a uniform nickel coating.

Durability: Wear and Corrosion Resistance

Nickel coins exhibit superior durability due to their high nickel content, which provides excellent wear and corrosion resistance, making them ideal for long circulation periods. In contrast, nickel-plated coins have a thinner layer of nickel over a base metal, which can wear away over time, exposing the underlying material to corrosion and reducing overall lifespan. The solid nickel structure in pure nickel coins ensures consistent performance under harsh conditions, unlike nickel-plated coins that may degrade faster with frequent handling.

Cost Comparison: Production and Material Expenses

Nickel coins typically incur higher production costs due to the expense of using pure nickel, which is more costly than the base metals in nickel-plated coins. Nickel-plated coins combine cheaper metals like copper or zinc with a thin nickel coating, significantly reducing material expenses while maintaining corrosion resistance. The overall cost efficiency of nickel-plated coins makes them a preferred choice for large-scale minting operations seeking budget optimization.

Appearance and Finish of Each Coin Type

Nickel coins typically feature a solid matte silver-gray appearance due to their high nickel content, providing durability and resistance to corrosion. Nickel-plated coins exhibit a brighter, shinier finish with a more reflective surface achieved by electroplating a base metal core, often copper or zinc, with a thin nickel layer. The plating process results in enhanced luster and uniformity but may show wear over time, revealing the underlying metal beneath the nickel coating.

Environmental Impact and Recycling

Nickel coins are composed primarily of 75% copper and 25% nickel, requiring extensive mining that contributes to habitat disruption and energy-intensive extraction processes. Nickel-plated coins use a base metal core, such as steel, coated with a thin layer of nickel, reducing the overall demand for raw nickel and lowering environmental strain. Recycling nickel-plated coins is more efficient due to the separation of metals, enabling recovery of both the core and plating materials, which lessens landfill waste and conserves natural resources.

Common Uses and Circulation History

Nickel coins are composed primarily of a nickel-copper alloy, offering durability and corrosion resistance ideal for frequent handling in currency systems worldwide. Nickel-plated coins feature a core made of cheaper metals such as copper or zinc, coated with a thin layer of nickel to achieve a similar metallic appearance while reducing production costs. Historically, solid nickel coins have been favored for their longevity in circulation, whereas nickel-plated coins became prevalent in modern minting to balance economic efficiency with the aesthetic and functional benefits of nickel.

Collectability and Market Value

Nickel coins, primarily composed of a copper-nickel alloy, often hold greater collectability due to their intrinsic metal content and historical significance, whereas nickel-plated coins typically lack collector appeal because their thin nickel coating diminishes durability and value. Market value for genuine nickel coins tends to appreciate over time, especially for rare mintages or error varieties, while nickel-plated coins are generally mass-produced with minimal investment potential. Collectors prioritize original nickel composition in coins, associating it with authenticity and long-term value retention in numismatic markets.

Nickel coin vs nickel-plated coin Infographic

materialdif.com

materialdif.com