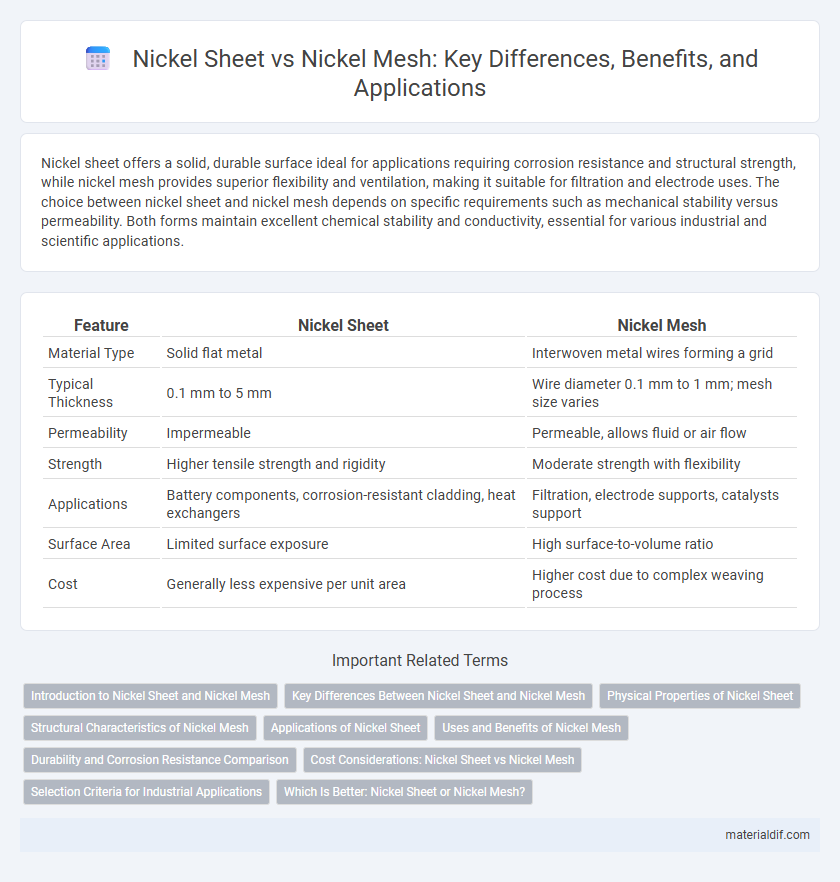

Nickel sheet offers a solid, durable surface ideal for applications requiring corrosion resistance and structural strength, while nickel mesh provides superior flexibility and ventilation, making it suitable for filtration and electrode uses. The choice between nickel sheet and nickel mesh depends on specific requirements such as mechanical stability versus permeability. Both forms maintain excellent chemical stability and conductivity, essential for various industrial and scientific applications.

Table of Comparison

| Feature | Nickel Sheet | Nickel Mesh |

|---|---|---|

| Material Type | Solid flat metal | Interwoven metal wires forming a grid |

| Typical Thickness | 0.1 mm to 5 mm | Wire diameter 0.1 mm to 1 mm; mesh size varies |

| Permeability | Impermeable | Permeable, allows fluid or air flow |

| Strength | Higher tensile strength and rigidity | Moderate strength with flexibility |

| Applications | Battery components, corrosion-resistant cladding, heat exchangers | Filtration, electrode supports, catalysts support |

| Surface Area | Limited surface exposure | High surface-to-volume ratio |

| Cost | Generally less expensive per unit area | Higher cost due to complex weaving process |

Introduction to Nickel Sheet and Nickel Mesh

Nickel sheet is a flat, solid metal form commonly used for its corrosion resistance, high thermal conductivity, and excellent mechanical strength in industrial applications such as batteries, aerospace, and chemical processing. Nickel mesh consists of woven or perforated nickel wires, offering superior filtration, electrical conductivity, and catalytic properties, making it ideal for use in electroplating, battery separators, and fuel cells. Understanding the distinct structural forms and functional benefits of nickel sheet versus nickel mesh helps optimize material selection for specific engineering and manufacturing needs.

Key Differences Between Nickel Sheet and Nickel Mesh

Nickel sheet offers a smooth, solid surface ideal for applications requiring durability and corrosion resistance, such as battery manufacturing and chemical processing. Nickel mesh provides a porous structure with enhanced surface area, making it suitable for filtration, catalysis, and electrode applications. The primary differences lie in physical form and application versatility, with sheets emphasizing structural strength and sheets optimized for permeability and surface interaction.

Physical Properties of Nickel Sheet

Nickel sheet exhibits a smooth, uniform surface with high tensile strength and excellent corrosion resistance, making it ideal for applications requiring durability and stability under high temperatures. Its dense and solid structure provides superior electrical conductivity and thermal expansion properties compared to nickel mesh. Unlike the porous and flexible nature of nickel mesh, nickel sheet offers a rigid and continuous barrier, enhancing mechanical robustness in aerospace, electronics, and chemical processing industries.

Structural Characteristics of Nickel Mesh

Nickel mesh features a porous, woven structure that provides enhanced flexibility and superior surface area compared to the solid, dense composition of nickel sheets. This open framework of nickel mesh allows for improved airflow, fluid permeability, and efficient filtration in various applications. Its structural characteristics make nickel mesh ideal for uses requiring mechanical strength combined with lightweight and high corrosion resistance.

Applications of Nickel Sheet

Nickel sheets are extensively used in applications requiring high corrosion resistance and durability, such as aerospace components, chemical processing equipment, and battery manufacturing. Their solid, flat form provides excellent strength and surface uniformity, making them ideal for heat exchangers and electrical contacts. Unlike nickel mesh, sheets offer superior mechanical stability for structural and protective uses across various industrial sectors.

Uses and Benefits of Nickel Mesh

Nickel mesh offers exceptional corrosion resistance and superior filtration capabilities compared to solid nickel sheets, making it ideal for applications in chemical processing, battery separators, and aerospace components. Its open structure allows for efficient airflow and liquid passage while providing mechanical strength, which is beneficial in catalytic converters and electromagnetic shielding. Unlike nickel sheets, nickel mesh is flexible and customizable in terms of pore size, enhancing its utility in environmental filtration and medical devices.

Durability and Corrosion Resistance Comparison

Nickel sheets offer superior durability due to their solid, continuous surface, making them highly resistant to mechanical wear and corrosion in harsh environments. Nickel mesh, while providing excellent corrosion resistance from its inherent nickel properties, may be less durable under mechanical stress because of its woven structure, which can be more susceptible to deformation or tearing. For applications requiring robust structural integrity and long-term corrosion resistance, nickel sheets are generally preferred over nickel mesh.

Cost Considerations: Nickel Sheet vs Nickel Mesh

Nickel sheets generally cost less than nickel mesh due to simpler manufacturing processes and lower material complexity. Nickel mesh, featuring a woven or perforated structure, often requires more intricate production techniques, increasing its price. The choice between nickel sheet and mesh depends on budget constraints and specific application needs, with sheets favored for cost-efficiency and mesh for specialized filtration or structural flexibility.

Selection Criteria for Industrial Applications

Nickel sheet offers excellent corrosion resistance and mechanical strength, making it ideal for structural applications and heat exchangers. Nickel mesh provides superior gas permeability and filtration capabilities, which are essential for catalyst supports and battery separators. Selection depends on factors such as required surface area, mechanical durability, and fluid flow characteristics for specific industrial processes.

Which Is Better: Nickel Sheet or Nickel Mesh?

Nickel sheet offers superior structural strength and corrosion resistance, making it ideal for applications requiring durability and uniformity, such as battery casings and aerospace components. Nickel mesh, with its high surface area and excellent permeability, is preferred in filtration, catalysis, and battery electrodes where enhanced fluid flow and reactivity are crucial. Choosing between nickel sheet and nickel mesh depends on specific application requirements, balancing mechanical properties versus surface interaction needs.

Nickel Sheet vs Nickel Mesh Infographic

materialdif.com

materialdif.com