Nickel offers exceptional corrosion resistance and high-temperature strength, making it ideal for demanding industrial applications. Monel, an alloy primarily composed of nickel and copper, provides superior resistance to acidic environments and seawater corrosion while maintaining excellent mechanical properties. Choosing between nickel and Monel depends on specific environmental conditions and mechanical requirements, with Monel being preferred for marine and chemical industries due to its enhanced durability.

Table of Comparison

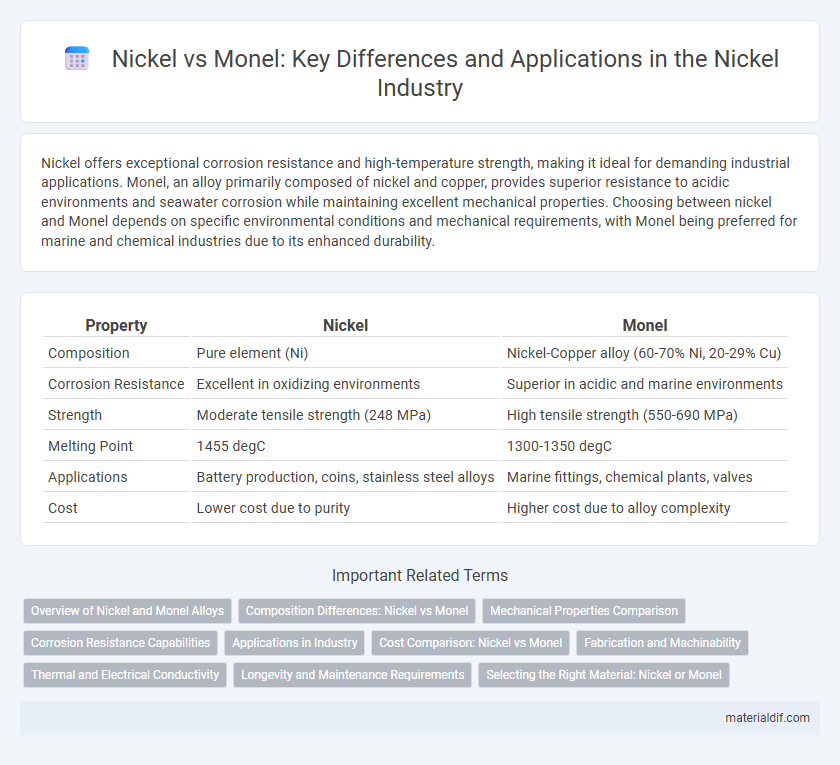

| Property | Nickel | Monel |

|---|---|---|

| Composition | Pure element (Ni) | Nickel-Copper alloy (60-70% Ni, 20-29% Cu) |

| Corrosion Resistance | Excellent in oxidizing environments | Superior in acidic and marine environments |

| Strength | Moderate tensile strength (248 MPa) | High tensile strength (550-690 MPa) |

| Melting Point | 1455 degC | 1300-1350 degC |

| Applications | Battery production, coins, stainless steel alloys | Marine fittings, chemical plants, valves |

| Cost | Lower cost due to purity | Higher cost due to alloy complexity |

Overview of Nickel and Monel Alloys

Nickel is a versatile element known for its excellent corrosion resistance, high melting point, and strong mechanical properties, making it essential in stainless steel and superalloys production. Monel alloys, primarily composed of nickel (typically 65-70%) and copper, offer superior resistance to seawater corrosion and acid environments, distinguishing them from pure nickel which excels in high-temperature oxidation resistance. While nickel provides a solid foundation in alloy development, Monel's unique combination of nickel and copper delivers enhanced durability and strength in marine and chemical applications.

Composition Differences: Nickel vs Monel

Nickel is a pure elemental metal primarily composed of about 99% nickel, known for its corrosion resistance and high melting point of 1455degC. Monel, an alloy mainly consisting of approximately 65-70% nickel and 20-29% copper, incorporates small amounts of iron, manganese, and carbon, enhancing its strength and resistance to corrosion in marine environments. The key composition difference lies in Monel's copper content, which significantly alters its mechanical properties and corrosion resistance compared to pure nickel.

Mechanical Properties Comparison

Nickel exhibits high tensile strength and excellent corrosion resistance, making it suitable for various industrial applications. Monel, an alloy primarily composed of nickel and copper, offers superior tensile strength and enhanced fatigue resistance compared to pure nickel, along with improved toughness in extreme temperature environments. Mechanical properties such as yield strength, elongation, and hardness are generally higher in Monel, providing greater durability and performance in demanding conditions.

Corrosion Resistance Capabilities

Nickel exhibits excellent corrosion resistance in various environments, especially against oxidation and alkaline conditions, making it ideal for harsh chemical applications. Monel, an alloy primarily composed of nickel and copper, offers superior resistance to seawater and acidic environments due to its enhanced strength and toughness. The combination of nickel and copper in Monel results in improved corrosion resistance over pure nickel in marine and industrial acid exposure scenarios.

Applications in Industry

Nickel is widely used in stainless steel production, chemical processing, and battery manufacturing due to its corrosion resistance and high-temperature strength. Monel, an alloy primarily composed of nickel and copper, excels in marine engineering, chemical processing, and aerospace applications because of its superior resistance to seawater and acids. Industries select Monel over pure nickel when enhanced toughness and weldability are critical for harsh environments.

Cost Comparison: Nickel vs Monel

Nickel generally has a lower cost compared to Monel, making it a more economical choice for applications requiring corrosion resistance and durability. Monel alloys, composed mainly of nickel and copper, command higher prices due to their superior strength and enhanced resistance to seawater and acidic environments. The price difference varies with market fluctuations but typically positions Nickel as the cost-effective option for less demanding industrial uses.

Fabrication and Machinability

Nickel offers excellent corrosion resistance and is easier to weld compared to Monel, making it favorable for fabrication processes requiring extensive welding and forming. Monel, an alloy primarily composed of nickel and copper, exhibits superior strength and toughness but presents more challenges in machining due to its tendency to work harden quickly. Machinability ratings indicate that pure nickel achieves better surface finishes and dimensional accuracy, while Monel requires specialized tooling to maintain efficiency and precision during cutting operations.

Thermal and Electrical Conductivity

Nickel exhibits thermal conductivity around 90 W/m*K and electrical conductivity of approximately 14 MS/m, making it a reliable choice for applications requiring moderate heat dissipation and electrical conduction. Monel, an alloy primarily composed of nickel and copper, displays lower thermal conductivity near 22 W/m*K but maintains comparable electrical conductivity ranging from 6 to 8 MS/m due to its mixed composition. The significant difference in thermal conductivity influences the selection between pure nickel and Monel in environments demanding efficient heat transfer or specific electrical performance.

Longevity and Maintenance Requirements

Nickel exhibits superior corrosion resistance and durability, resulting in extended longevity compared to Monel, which is an alloy primarily composed of nickel and copper but tends to require more frequent maintenance due to its susceptibility to stress corrosion cracking in certain environments. Monel's maintenance needs increase in marine or acidic conditions where nickel's robust oxide layer offers better protection and prolonged lifespan. Choosing nickel for applications demanding minimal upkeep ensures cost efficiency through reduced maintenance intervals and enhanced material stability.

Selecting the Right Material: Nickel or Monel

Selecting the right material between Nickel and Monel depends on the application's corrosion resistance, strength, and cost requirements. Nickel offers excellent resistance to oxidation and various corrosive environments, making it ideal for chemical processing equipment. Monel, an alloy predominantly composed of Nickel and Copper, provides superior strength and resistance to seawater corrosion, making it more suitable for marine and marine-related applications.

Nickel vs Monel Infographic

materialdif.com

materialdif.com