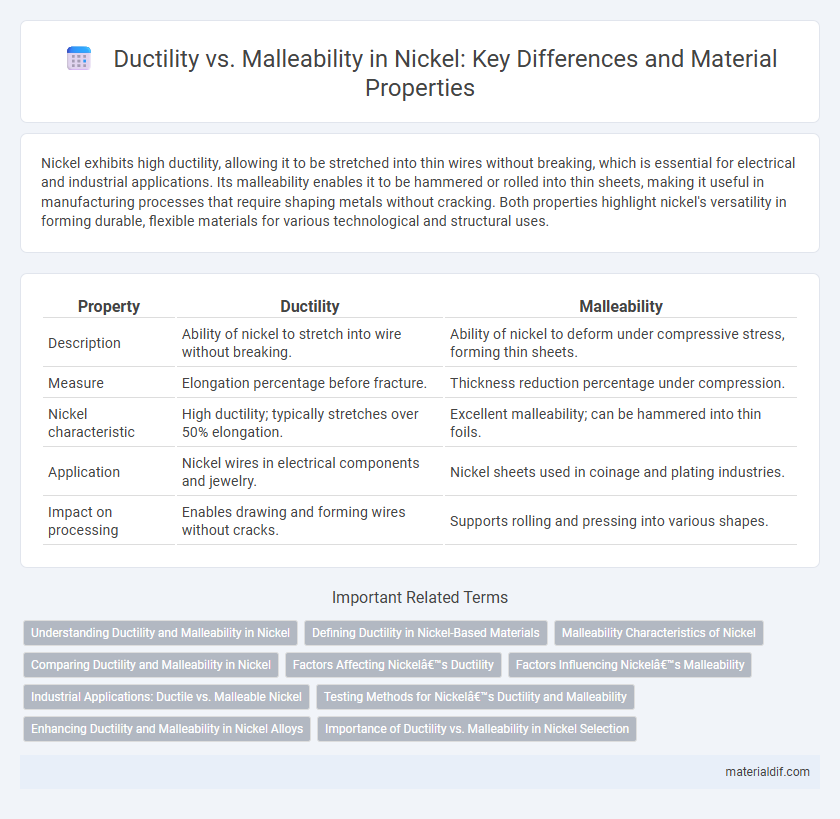

Nickel exhibits high ductility, allowing it to be stretched into thin wires without breaking, which is essential for electrical and industrial applications. Its malleability enables it to be hammered or rolled into thin sheets, making it useful in manufacturing processes that require shaping metals without cracking. Both properties highlight nickel's versatility in forming durable, flexible materials for various technological and structural uses.

Table of Comparison

| Property | Ductility | Malleability |

|---|---|---|

| Description | Ability of nickel to stretch into wire without breaking. | Ability of nickel to deform under compressive stress, forming thin sheets. |

| Measure | Elongation percentage before fracture. | Thickness reduction percentage under compression. |

| Nickel characteristic | High ductility; typically stretches over 50% elongation. | Excellent malleability; can be hammered into thin foils. |

| Application | Nickel wires in electrical components and jewelry. | Nickel sheets used in coinage and plating industries. |

| Impact on processing | Enables drawing and forming wires without cracks. | Supports rolling and pressing into various shapes. |

Understanding Ductility and Malleability in Nickel

Nickel exhibits high ductility, allowing it to be stretched into thin wires without breaking, which is crucial for applications in electrical wiring and flexible components. Its malleability enables nickel to be hammered or rolled into thin sheets, making it ideal for plating and alloy production. The combination of ductility and malleability in nickel results from its face-centered cubic (FCC) crystal structure, which facilitates dislocation movement under stress.

Defining Ductility in Nickel-Based Materials

Ductility in nickel-based materials refers to their ability to undergo significant plastic deformation before fracture, measured by percent elongation or reduction in area during tensile testing. This property is crucial for nickel alloys used in aerospace and industrial applications, where materials must withstand high stresses without cracking. High ductility in nickel enhances formability and toughness, distinguishing it from malleability, which specifically describes the ease of deformation under compressive stress.

Malleability Characteristics of Nickel

Nickel exhibits high malleability, allowing it to be hammered or rolled into thin sheets without breaking, which is essential in metalworking and industrial applications. Its atomic structure enables nickel to deform plastically under compressive stress, making it ideal for manufacturing processes such as coinage and plating. This malleability enhances nickel's versatility in creating durable and corrosion-resistant components across aerospace, electronics, and automotive industries.

Comparing Ductility and Malleability in Nickel

Nickel exhibits high ductility, allowing it to be stretched into thin wires without breaking, which is essential for electrical and industrial applications. Its malleability enables it to be hammered or rolled into thin sheets, making it suitable for manufacturing coins and plating materials. Compared to many metals, nickel's balanced combination of ductility and malleability contributes to its versatility in various engineering and chemical processes.

Factors Affecting Nickel’s Ductility

Nickel's ductility is influenced by factors such as temperature, alloy composition, and crystal structure, with higher temperatures generally enhancing its ability to deform plastically without fracture. Impurities and the presence of alloying elements like carbon or sulfur can reduce ductility by creating stress concentration points within the metal's grain boundaries. The face-centered cubic (FCC) crystal structure of nickel provides multiple slip systems, promoting ductility as compared to metals with body-centered cubic (BCC) structures, making it less malleable but highly ductile under tensile stress.

Factors Influencing Nickel’s Malleability

Nickel's malleability is primarily influenced by its atomic structure and the presence of impurities, which can disrupt the metal's ability to deform plastically without fracture. Temperature plays a crucial role, as higher temperatures increase atomic mobility, enhancing nickel's malleability by allowing easier slip along crystal planes. Grain size and the rate of deformation also significantly affect nickel's malleability, with finer grains and slower deformation rates promoting a more malleable behavior.

Industrial Applications: Ductile vs. Malleable Nickel

Nickel exhibits high ductility, allowing it to be drawn into fine wires for use in electrical components and heating elements, whereas its moderate malleability enables shaping into sheets and foils for catalytic converters and coinage. The ductile properties of nickel optimize performance in applications requiring tensile strength and flexibility, such as aerospace wiring and battery electrodes. Industrial processes leverage nickel's malleability for producing corrosion-resistant cladding and plating materials that maintain structural integrity under mechanical stress.

Testing Methods for Nickel’s Ductility and Malleability

Nickel's ductility and malleability are evaluated through standardized mechanical testing methods such as tensile tests, which measure elongation and reduction in area to determine ductility, and compression or stress-strain tests to assess malleability. Microstructural analysis using scanning electron microscopy (SEM) complements these tests by revealing deformation mechanisms and grain boundary behavior under stress. These testing methods provide critical data on nickel's performance in applications requiring both shape manipulation and structural integrity.

Enhancing Ductility and Malleability in Nickel Alloys

Nickel alloys exhibit enhanced ductility and malleability through controlled alloying with elements like copper, chromium, and iron, which refine the microstructure and improve workability. Heat treatment processes, including annealing, optimize the dislocation movement within the nickel matrix, contributing to increased plastic deformation capability without fracture. These enhancements enable nickel alloys to perform reliably in demanding applications such as aerospace components and chemical processing equipment.

Importance of Ductility vs. Malleability in Nickel Selection

Nickel's high ductility allows it to be drawn into thin wires without fracturing, essential for electrical applications and fine components. Its malleability enables efficient shaping and forming into sheets or foils, critical for manufacturing durable industrial parts. Selecting nickel based on ductility versus malleability optimizes performance in specific uses, such as wiring or structural components, where either flexibility or formability is paramount.

Ductility vs malleability (for nickel) Infographic

materialdif.com

materialdif.com