Electroformed nickel offers superior precision and uniform thickness compared to electroplated nickel, making it ideal for intricate components requiring consistent performance. Electroplated nickel, while faster and more cost-effective, typically results in thinner coatings with less structural integrity. Choosing between electroformed and electroplated nickel depends on balancing requirements for durability, detail accuracy, and budget constraints.

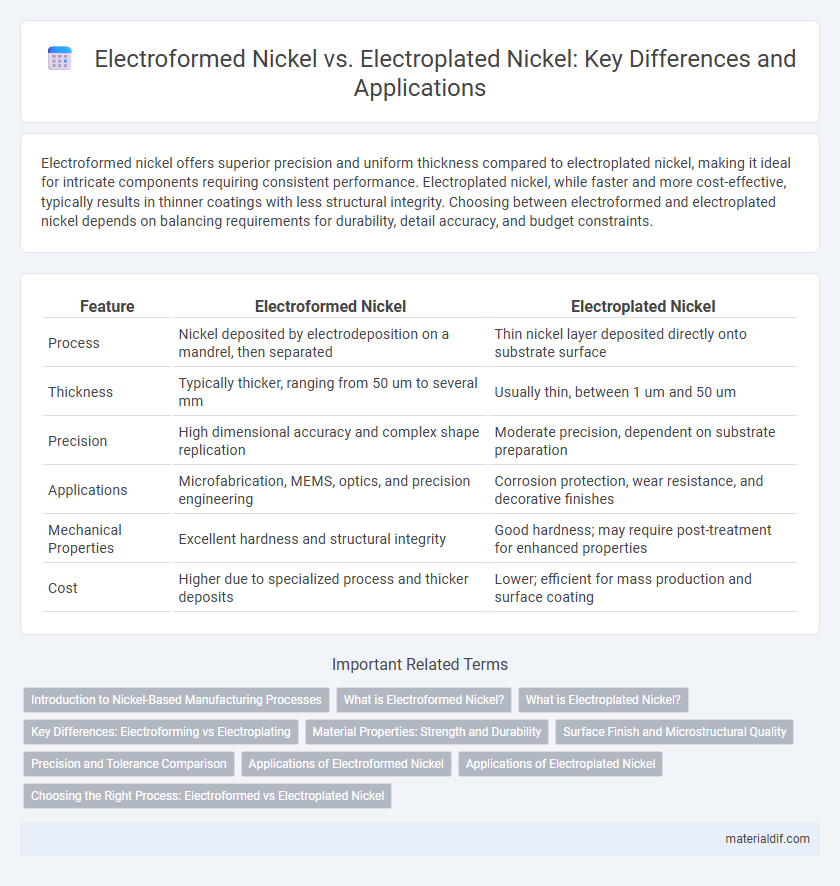

Table of Comparison

| Feature | Electroformed Nickel | Electroplated Nickel |

|---|---|---|

| Process | Nickel deposited by electrodeposition on a mandrel, then separated | Thin nickel layer deposited directly onto substrate surface |

| Thickness | Typically thicker, ranging from 50 um to several mm | Usually thin, between 1 um and 50 um |

| Precision | High dimensional accuracy and complex shape replication | Moderate precision, dependent on substrate preparation |

| Applications | Microfabrication, MEMS, optics, and precision engineering | Corrosion protection, wear resistance, and decorative finishes |

| Mechanical Properties | Excellent hardness and structural integrity | Good hardness; may require post-treatment for enhanced properties |

| Cost | Higher due to specialized process and thicker deposits | Lower; efficient for mass production and surface coating |

Introduction to Nickel-Based Manufacturing Processes

Electroformed nickel involves precise deposition of nickel layers onto a mandrel, creating seamless, high-strength components ideal for complex geometries in aerospace and electronics industries. Electroplated nickel, by contrast, coats a substrate with a thin nickel layer to enhance corrosion resistance, wear properties, and aesthetic appeal, commonly used in automotive and decorative applications. Both processes leverage nickel's excellent mechanical properties and corrosion resistance but differ significantly in their manufacturing techniques and end-use performance.

What is Electroformed Nickel?

Electroformed nickel is a precision manufacturing process where nickel is deposited onto a mandrel to create a thick, self-supporting metal layer that can be separated from the mold. This technique enables the production of complex, high-strength components with superior dimensional accuracy and uniform wall thickness compared to electroplated nickel. Unlike electroplating, which applies a thin surface coating, electroforming builds up substantial metal structures ideal for aerospace, optical, and microfabrication industries.

What is Electroplated Nickel?

Electroplated nickel is a surface coating process where a thin layer of nickel is deposited onto a substrate through electrochemical deposition, enhancing corrosion resistance and surface hardness. This technique offers precise thickness control and uniform coverage, widely used in automotive, electronics, and jewelry industries. Unlike electroformed nickel, which builds up the metal as a self-supporting structure, electroplating applies nickel as a thin surface layer on existing materials.

Key Differences: Electroforming vs Electroplating

Electroformed nickel involves building up a thick, self-supporting metal layer by depositing nickel ions onto a mandrel, resulting in precise, intricate shapes with high mechanical strength and excellent dimensional accuracy. Electroplated nickel, in contrast, deposits a thin nickel coating onto a substrate to enhance surface properties such as corrosion resistance, wear resistance, and aesthetic appeal without significantly altering the part's dimensions. The key difference lies in electroforming producing a standalone metal part through additive layering, while electroplating provides a surface finish onto an existing component.

Material Properties: Strength and Durability

Electroformed nickel exhibits superior strength and durability compared to electroplated nickel due to its denser microstructure and uniform thickness achieved through the electroforming process. The material properties of electroformed nickel include enhanced wear resistance and higher tensile strength, making it suitable for precision applications requiring long-term reliability. In contrast, electroplated nickel often has a thinner, less consistent layer that may be more prone to cracking and corrosion under stress.

Surface Finish and Microstructural Quality

Electroformed nickel exhibits superior surface finish compared to electroplated nickel due to its uniform grain structure and lower internal stress, resulting in smoother, more consistent coatings ideal for high-precision applications. The microstructural quality of electroformed nickel is characterized by a dense, fine-grained matrix that enhances mechanical strength and corrosion resistance, whereas electroplated nickel often shows coarser grains and potential porosity. These differences significantly impact performance in industries like electronics and aerospace, where surface integrity and material uniformity are critical.

Precision and Tolerance Comparison

Electroformed nickel offers superior precision and tighter tolerances compared to electroplated nickel due to its layer-by-layer build-up process that allows for exact replication of intricate details and complex geometries. This additive manufacturing technique achieves thickness control within microns, making it ideal for applications requiring high dimensional accuracy such as semiconductor masks and aerospace components. In contrast, electroplated nickel, deposited through a diffusion process, often results in less uniform thickness and greater variability in surface finish, limiting its use in precision-critical industries.

Applications of Electroformed Nickel

Electroformed nickel is widely used in precision engineering applications such as producing seamless, highly detailed components for aerospace and electronics industries due to its excellent dimensional stability and mechanical strength. Its ability to create complex, thin-walled structures makes it ideal for photomask production and micromachining in semiconductor fabrication. Electroplated nickel, by contrast, is typically employed for surface hardening and corrosion resistance, but lacks the structural precision required in these advanced manufacturing processes.

Applications of Electroplated Nickel

Electroplated nickel is widely used in automotive components, electronics, and decorative finishes due to its excellent corrosion resistance and ability to provide a smooth, uniform coating. It enhances surface hardness and wear resistance, making it ideal for aerospace turbine blades and precision instruments. The process is favored in manufacturing environments requiring cost-effective, high-quality protective layers.

Choosing the Right Process: Electroformed vs Electroplated Nickel

Electroformed nickel offers precise thickness control and exceptional structural integrity, making it ideal for complex molds and high-precision components. Electroplated nickel provides excellent surface finish and corrosion resistance, suitable for decorative coatings and wear-resistant layers. Selecting between electroformed and electroplated nickel depends on specific application requirements such as mechanical strength, dimensional accuracy, and surface properties.

Electroformed Nickel vs Electroplated Nickel Infographic

materialdif.com

materialdif.com