Nickel sheets offer greater thickness and durability, making them ideal for structural applications requiring strength and stability. Nickel foils are thinner and more flexible, suitable for precise, lightweight uses such as battery electrodes and flexible electronics. Choosing between nickel sheet and foil depends on the specific requirements for thickness, flexibility, and mechanical strength in your project.

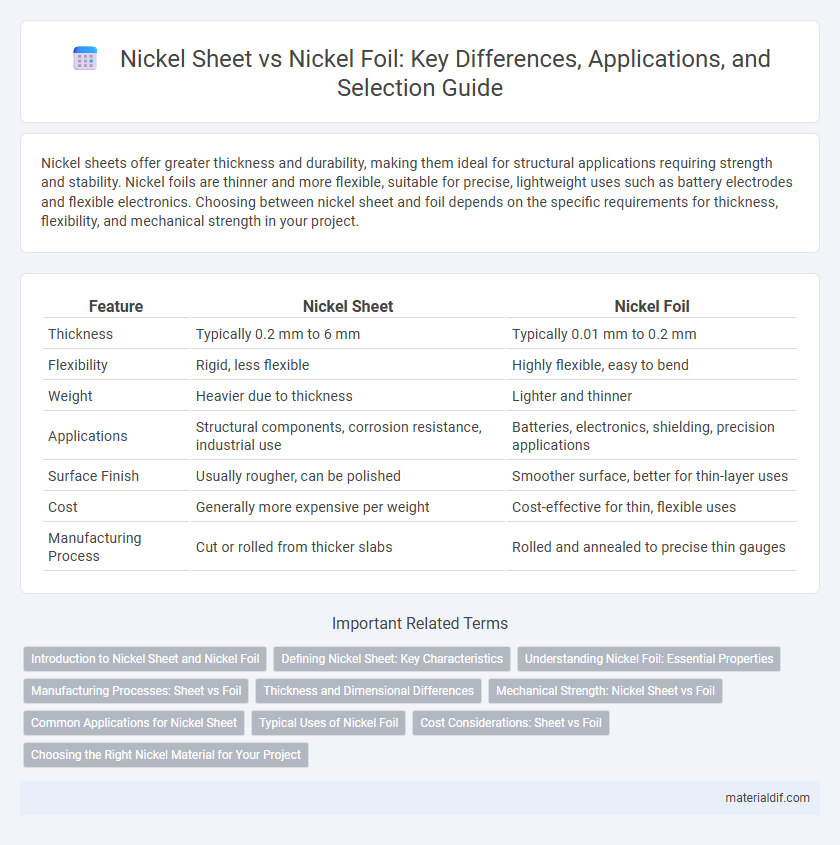

Table of Comparison

| Feature | Nickel Sheet | Nickel Foil |

|---|---|---|

| Thickness | Typically 0.2 mm to 6 mm | Typically 0.01 mm to 0.2 mm |

| Flexibility | Rigid, less flexible | Highly flexible, easy to bend |

| Weight | Heavier due to thickness | Lighter and thinner |

| Applications | Structural components, corrosion resistance, industrial use | Batteries, electronics, shielding, precision applications |

| Surface Finish | Usually rougher, can be polished | Smoother surface, better for thin-layer uses |

| Cost | Generally more expensive per weight | Cost-effective for thin, flexible uses |

| Manufacturing Process | Cut or rolled from thicker slabs | Rolled and annealed to precise thin gauges |

Introduction to Nickel Sheet and Nickel Foil

Nickel sheet and nickel foil are both widely used forms of nickel metal, characterized by their thickness and manufacturing process. Nickel sheets are thicker, ranging from 0.5mm to several millimeters, commonly utilized in structural applications, corrosion resistance, and industrial fabrication. Nickel foil is significantly thinner, often less than 0.2mm, ideal for flexible applications such as battery electrodes, electrical shielding, and precision components.

Defining Nickel Sheet: Key Characteristics

Nickel sheet is a flat, rigid metal product typically thicker than 0.2 mm, offering enhanced strength and structural integrity compared to thinner forms like nickel foil. It provides excellent corrosion resistance, high melting point, and superior durability, making it ideal for demanding industrial applications such as heat exchangers, battery casings, and aerospace components. The rigid form of nickel sheet allows for machining and welding, distinguishing it from more flexible and delicate nickel foil used primarily in electronic and specialty applications.

Understanding Nickel Foil: Essential Properties

Nickel foil is a thin, flexible metal sheet commonly ranging from 0.005 mm to 0.2 mm in thickness, known for its high tensile strength and excellent corrosion resistance in harsh environments. Unlike thicker nickel sheets, nickel foil offers superior pliability and is widely used in electronics, battery manufacturing, and shielding applications due to its excellent conductivity and durability. Key properties include a high melting point of 1455degC, resistance to oxidation, and the ability to maintain structural integrity under thermal stress, making it indispensable for specialized industrial uses.

Manufacturing Processes: Sheet vs Foil

Nickel sheet is produced by hot rolling and cold rolling processes, resulting in thicker, rigid material ideal for structural applications. Nickel foil undergoes a more refined manufacturing process, starting with cold rolling followed by annealing and final cold rolling to achieve ultra-thin, flexible sheets used in electronics and rechargeable batteries. The controlled thickness and uniformity in nickel foil manufacturing enable superior electrical conductivity and mechanical performance compared to nickel sheets.

Thickness and Dimensional Differences

Nickel sheet typically ranges in thickness from 0.2 mm to 3 mm, offering greater rigidity and structural support compared to nickel foil, which is much thinner, usually between 0.01 mm and 0.2 mm. The dimensional differences mean nickel sheet is preferred for applications demanding durability and load-bearing capacity, while nickel foil is ideal for flexible, lightweight uses such as battery electrodes and shielding. Thickness directly influences the mechanical properties, with sheets providing superior strength and foils enabling conformability in complex geometries.

Mechanical Strength: Nickel Sheet vs Foil

Nickel sheet exhibits significantly higher mechanical strength compared to nickel foil due to its greater thickness and structural integrity, making it more suitable for applications requiring durability and resistance to deformation. Nickel foil, being thinner and more flexible, offers less mechanical strength but excels in applications where lightweight and conformability are essential. The choice between nickel sheet and foil depends on balancing strength requirements with flexibility and weight considerations in industrial and manufacturing processes.

Common Applications for Nickel Sheet

Nickel sheet is widely used in aerospace, chemical processing, and electronics industries due to its excellent corrosion resistance and high strength at elevated temperatures. Its durability makes it ideal for heat exchangers, batteries, and turbine blades where structural integrity is critical. Unlike nickel foil, which is thinner and more flexible, nickel sheet provides robust mechanical support in demanding industrial applications.

Typical Uses of Nickel Foil

Nickel foil is commonly used in battery manufacturing, particularly for lithium-ion batteries, due to its excellent conductivity and flexibility, which supports efficient current collection. It also finds applications in chemical processing as a corrosion-resistant barrier and in electrical components for shielding and insulation purposes. Nickel foil's thin, pliable nature makes it ideal for precision applications requiring lightweight and durable materials.

Cost Considerations: Sheet vs Foil

Nickel sheet generally costs less per unit area compared to nickel foil due to its thicker gauge and simpler manufacturing process, making it more economical for applications requiring durability and rigidity. Nickel foil, being thinner and often produced through specialized rolling techniques, incurs higher production costs but offers superior flexibility and precision for delicate or electronic uses. Choosing between nickel sheet and foil hinges on balancing initial material expenses with specific functional requirements, where foil's higher cost is offset by performance benefits in advanced technological applications.

Choosing the Right Nickel Material for Your Project

Nickel sheet offers greater thickness and mechanical strength, ideal for structural applications requiring durability and resistance to corrosion. Nickel foil provides superior flexibility and a thinner profile, making it suitable for delicate electronic components and heat shielding in tight spaces. Selecting the appropriate nickel material depends on the specific application demands such as mechanical stress, thermal conductivity, and formability.

Nickel Sheet vs Nickel Foil Infographic

materialdif.com

materialdif.com