Nickel ferrite and nickel chromite are both important nickel-based spinel compounds with distinct magnetic and catalytic properties. Nickel ferrite (NiFe2O4) exhibits strong magnetic characteristics making it valuable in electromagnetic applications, while nickel chromite (NiCr2O4) is favored for high-temperature stability and corrosion resistance. Understanding the differences in their crystal structures and thermal behavior is essential for optimizing their use in catalysts, sensors, and magnetic materials.

Table of Comparison

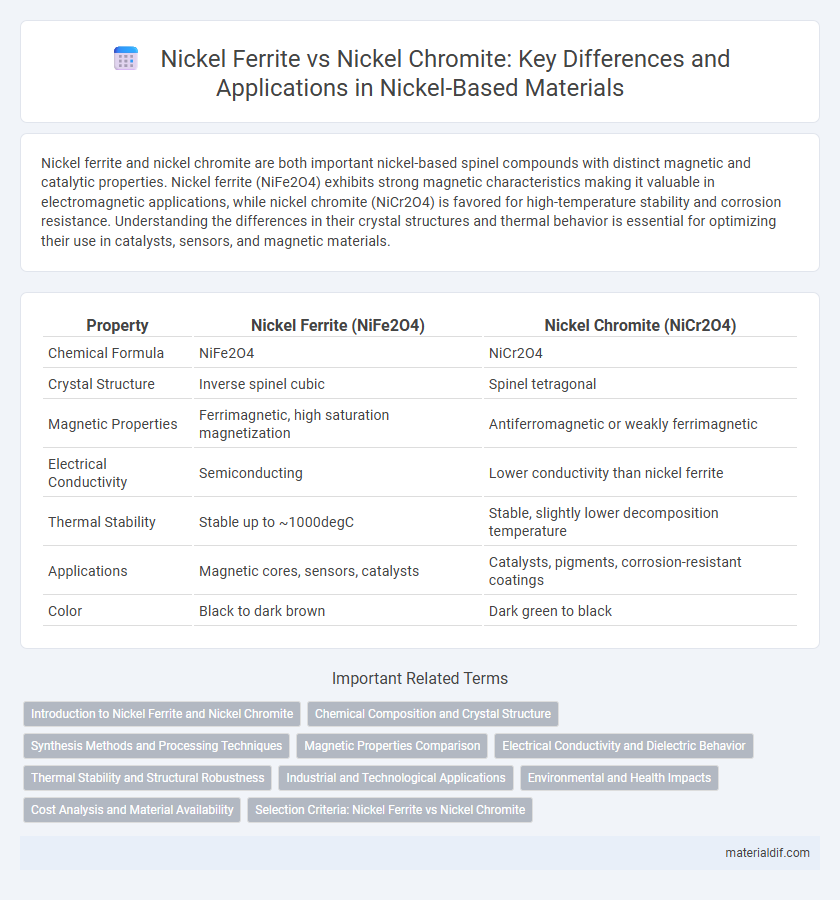

| Property | Nickel Ferrite (NiFe2O4) | Nickel Chromite (NiCr2O4) |

|---|---|---|

| Chemical Formula | NiFe2O4 | NiCr2O4 |

| Crystal Structure | Inverse spinel cubic | Spinel tetragonal |

| Magnetic Properties | Ferrimagnetic, high saturation magnetization | Antiferromagnetic or weakly ferrimagnetic |

| Electrical Conductivity | Semiconducting | Lower conductivity than nickel ferrite |

| Thermal Stability | Stable up to ~1000degC | Stable, slightly lower decomposition temperature |

| Applications | Magnetic cores, sensors, catalysts | Catalysts, pigments, corrosion-resistant coatings |

| Color | Black to dark brown | Dark green to black |

Introduction to Nickel Ferrite and Nickel Chromite

Nickel ferrite (NiFe2O4) is a spinel-type ferrite known for its magnetic properties and applications in catalysis, sensors, and data storage, characterized by a cubic crystal structure and mixed oxidation states of nickel and iron. Nickel chromite (NiCr2O4) also adopts a spinel structure but features chromium, imparting distinct catalytic activity and corrosion resistance, making it valuable in chemical synthesis and refractory materials. The differences in metal cation composition and electronic configuration between nickel ferrite and nickel chromite result in varied magnetic, catalytic, and structural properties critical for industrial and technological applications.

Chemical Composition and Crystal Structure

Nickel ferrite (NiFe2O4) is a spinel-type oxide with a cubic crystal structure, composed primarily of nickel, iron, and oxygen ions arranged in a face-centered cubic lattice. Nickel chromite (NiCr2O4) also exhibits a spinel structure but contains nickel, chromium, and oxygen, resulting in differences in magnetic and electrical properties due to the substitution of iron by chromium ions. The variation in chemical composition between NiFe2O4 and NiCr2O4 leads to distinct cation distributions within the octahedral and tetrahedral sites of the crystal lattice, influencing their respective physical characteristics.

Synthesis Methods and Processing Techniques

Nickel ferrite (NiFe2O4) is predominantly synthesized using methods such as sol-gel, co-precipitation, and hydrothermal techniques, which facilitate controlled particle size and magnetic properties crucial for electronic applications. In contrast, nickel chromite (NiCr2O4) is commonly produced through solid-state reactions and combustion synthesis, enabling high thermal stability and catalytic efficiency. Processing techniques for nickel ferrite often involve calcination at moderate temperatures to enhance crystallinity, whereas nickel chromite requires higher temperature sintering to achieve optimal phase purity and mechanical strength.

Magnetic Properties Comparison

Nickel ferrite (NiFe2O4) exhibits strong ferrimagnetic behavior with a high Curie temperature around 858 K, making it suitable for high-frequency magnetic applications. In contrast, nickel chromite (NiCr2O4) displays antiferromagnetic properties with a lower Neel temperature near 68 K, resulting in weaker magnetic ordering. The difference in cation distribution and crystal structure between nickel ferrite's spinel phase and nickel chromite's distorted spinel phase critically influences their magnetic susceptibilities and coercivities.

Electrical Conductivity and Dielectric Behavior

Nickel ferrite (NiFe2O4) exhibits moderate electrical conductivity due to its spinel structure, which facilitates electron hopping between Fe2+ and Fe3+ ions, making it suitable for electromagnetic applications. Nickel chromite (NiCr2O4), on the other hand, displays lower electrical conductivity but enhanced dielectric properties attributed to its distorted spinel lattice and electron localization effects. The dielectric behavior of nickel chromite is characterized by higher dielectric constants and loss factors compared to nickel ferrite, influencing its use in capacitors and insulators.

Thermal Stability and Structural Robustness

Nickel ferrite (NiFe2O4) exhibits superior thermal stability due to its spinel structure, which maintains integrity at temperatures above 800degC, making it suitable for high-temperature applications. In contrast, nickel chromite (NiCr2O4) demonstrates enhanced structural robustness with higher resistance to mechanical stress but experiences phase transitions at lower temperatures around 600degC, limiting its high-temperature performance. The thermal endurance of nickel ferrite combined with the mechanical strength of nickel chromite informs material selection for catalysis and refractory uses.

Industrial and Technological Applications

Nickel ferrite (NiFe2O4) and nickel chromite (NiCr2O4) serve distinct roles in industrial and technological applications due to their unique magnetic and catalytic properties. Nickel ferrite is widely utilized in electromagnetic devices, sensors, and as a catalyst in wastewater treatment because of its high electrical conductivity and magnetic permeability. In contrast, nickel chromite's stability and chromium content make it ideal for high-temperature applications, refractory materials, and corrosion-resistant coatings in aerospace and chemical industries.

Environmental and Health Impacts

Nickel ferrite, a spinel-type oxide, exhibits lower environmental toxicity compared to nickel chromite, which contains hexavalent chromium known for its carcinogenic and mutagenic properties. Exposure to nickel chromite dust poses significant respiratory health risks, including lung inflammation and increased incidence of lung cancer, whereas nickel ferrite shows reduced bioavailability and lesser oxidative stress in biological systems. Environmental persistence and bioaccumulation are more pronounced in nickel chromite, making it a greater concern for long-term ecosystem contamination and human health impacts.

Cost Analysis and Material Availability

Nickel ferrite typically offers a lower cost due to more abundant raw materials and straightforward synthesis processes compared to nickel chromite, which relies on less common chromium sources leading to higher expenses. Material availability heavily favors nickel ferrite as nickel and iron precursors are more widely distributed globally, whereas chromium supply constraints can limit nickel chromite production scalability. Cost-effective nickel ferrite production and broader accessibility of iron compounds make it a preferred choice in applications where budget and resource availability are critical.

Selection Criteria: Nickel Ferrite vs Nickel Chromite

Nickel ferrite and nickel chromite differ significantly in magnetic properties and chemical stability, influencing their selection for specific applications. Nickel ferrite exhibits higher electrical resistivity and superior magnetic permeability, making it ideal for high-frequency electromagnetic devices and microwave applications. In contrast, nickel chromite offers enhanced thermal stability and corrosion resistance, preferred in refractory materials and high-temperature catalysis.

Nickel ferrite vs Nickel chromite Infographic

materialdif.com

materialdif.com