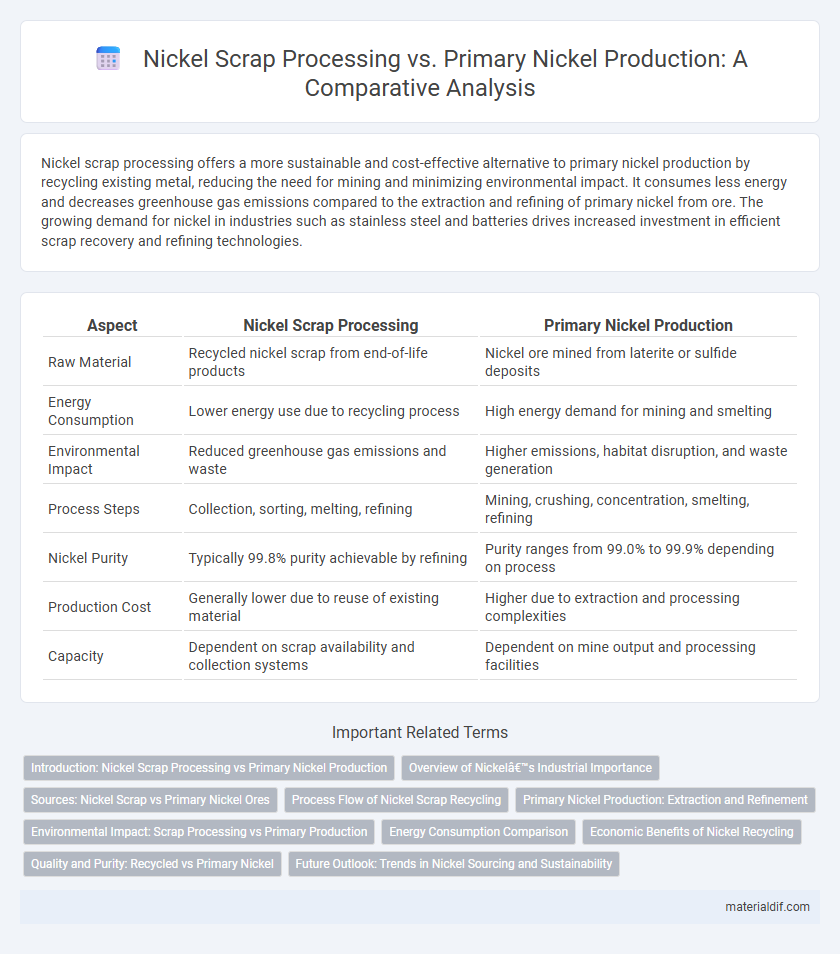

Nickel scrap processing offers a more sustainable and cost-effective alternative to primary nickel production by recycling existing metal, reducing the need for mining and minimizing environmental impact. It consumes less energy and decreases greenhouse gas emissions compared to the extraction and refining of primary nickel from ore. The growing demand for nickel in industries such as stainless steel and batteries drives increased investment in efficient scrap recovery and refining technologies.

Table of Comparison

| Aspect | Nickel Scrap Processing | Primary Nickel Production |

|---|---|---|

| Raw Material | Recycled nickel scrap from end-of-life products | Nickel ore mined from laterite or sulfide deposits |

| Energy Consumption | Lower energy use due to recycling process | High energy demand for mining and smelting |

| Environmental Impact | Reduced greenhouse gas emissions and waste | Higher emissions, habitat disruption, and waste generation |

| Process Steps | Collection, sorting, melting, refining | Mining, crushing, concentration, smelting, refining |

| Nickel Purity | Typically 99.8% purity achievable by refining | Purity ranges from 99.0% to 99.9% depending on process |

| Production Cost | Generally lower due to reuse of existing material | Higher due to extraction and processing complexities |

| Capacity | Dependent on scrap availability and collection systems | Dependent on mine output and processing facilities |

Introduction: Nickel Scrap Processing vs Primary Nickel Production

Nickel scrap processing recycles valuable materials from used products, reducing reliance on mining and lowering environmental impact by conserving natural resources. Primary nickel production involves extracting nickel ore through mining and refining, which is energy-intensive and generates significant waste. Advances in scrap processing technology enhance resource efficiency, supporting sustainable nickel supply chains and meeting growing global demand.

Overview of Nickel’s Industrial Importance

Nickel scrap processing plays a critical role in the global nickel supply chain by recycling valuable nickel from end-of-life products, reducing dependence on energy-intensive primary nickel production from laterite and sulfide ores. Primary nickel production remains essential for meeting industrial demand, particularly in stainless steel manufacturing, battery cathodes, and aerospace applications due to its high purity and consistent quality. Efficient integration of scrap recycling with primary production supports sustainability goals and stabilizes nickel market prices amid rising demand in electric vehicle technologies.

Sources: Nickel Scrap vs Primary Nickel Ores

Nickel scrap processing increasingly supplements primary nickel production by recovering valuable metals from industrial and consumer waste, reducing reliance on environmentally intensive nickel ore extraction. Primary nickel ores, predominantly laterites and sulfides, continue to supply the bulk of global nickel demand but face challenges such as higher energy consumption and environmental concerns. Efficient recycling of nickel scrap not only conserves natural resources but also supports the circular economy within the nickel supply chain.

Process Flow of Nickel Scrap Recycling

Nickel scrap recycling involves collection, sorting, and shredding of nickel-containing materials, followed by smelting or hydrometallurgical processing to extract pure nickel metal. This process flow reduces energy consumption and environmental impact compared to primary nickel production, which requires mining, ore beneficiation, and high-temperature smelting of laterite or sulfide ores. Efficient nickel scrap processing supports circular economy goals by recovering valuable metals while minimizing waste and greenhouse gas emissions.

Primary Nickel Production: Extraction and Refinement

Primary nickel production involves extracting nickel ore from mines followed by processes such as crushing, grinding, and flotation to concentrate the ore. The concentrate undergoes smelting and refining techniques like pyrometallurgy or hydrometallurgy to produce high-purity nickel suitable for industrial applications. This method yields nickel with consistent quality and higher metal recovery rates compared to nickel scrap processing, which relies on recycling and often results in variable nickel content.

Environmental Impact: Scrap Processing vs Primary Production

Nickel scrap processing significantly reduces environmental impact compared to primary nickel production, as it consumes less energy and decreases greenhouse gas emissions by up to 60%. Recycling nickel scrap minimizes mining activities, thereby reducing land degradation, water pollution, and biodiversity loss associated with ore extraction. The transition to scrap processing promotes sustainable resource management through efficient material reuse and waste reduction.

Energy Consumption Comparison

Nickel scrap processing consumes significantly less energy than primary nickel production, with estimates showing up to 90% reduction in energy use due to recycling metallic nickel directly from scrap. Primary nickel extraction from laterite or sulfide ores requires energy-intensive mining, smelting, and refining processes that contribute to higher carbon emissions. Utilizing recycled nickel scrap not only reduces overall energy consumption but also lowers environmental impact and conserves natural resources.

Economic Benefits of Nickel Recycling

Nickel scrap processing offers significant economic benefits compared to primary nickel production by reducing energy consumption by up to 40% and lowering production costs through the reuse of valuable metals. Recycling nickel decreases dependency on mining activities, which are often expensive and environmentally intensive, providing a more sustainable and cost-effective supply chain. Furthermore, recycled nickel maintains high purity standards, ensuring quality while stabilizing market supply and prices.

Quality and Purity: Recycled vs Primary Nickel

Nickel scrap processing yields recycled nickel with variable purity levels typically ranging from 95% to 99%, depending on the source and refining techniques, whereas primary nickel production from laterite or sulfide ores consistently achieves purity above 99.8%. The quality of recycled nickel often contains trace impurities such as copper, iron, and cobalt, while primary nickel offers superior metallurgical properties crucial for high-performance applications like stainless steel and battery manufacturing. Advances in hydrometallurgical refining have improved the purity of recycled nickel, narrowing the gap but primary nickel still dominates in applications requiring ultra-high purity and consistent chemical composition.

Future Outlook: Trends in Nickel Sourcing and Sustainability

Nickel scrap processing is gaining momentum as a sustainable alternative to primary nickel production, driven by increasing demand for environmentally friendly supply chains and advancements in recycling technologies. Future trends indicate a significant rise in the use of recycled nickel from stainless steel scrap and lithium-ion battery waste, reducing dependence on environmentally intensive mining operations. Sustainable nickel sourcing is becoming a critical focus for industries such as electric vehicle manufacturing, prompting investments in circular economy initiatives and cleaner processing methods.

Nickel Scrap Processing vs Primary Nickel Production Infographic

materialdif.com

materialdif.com