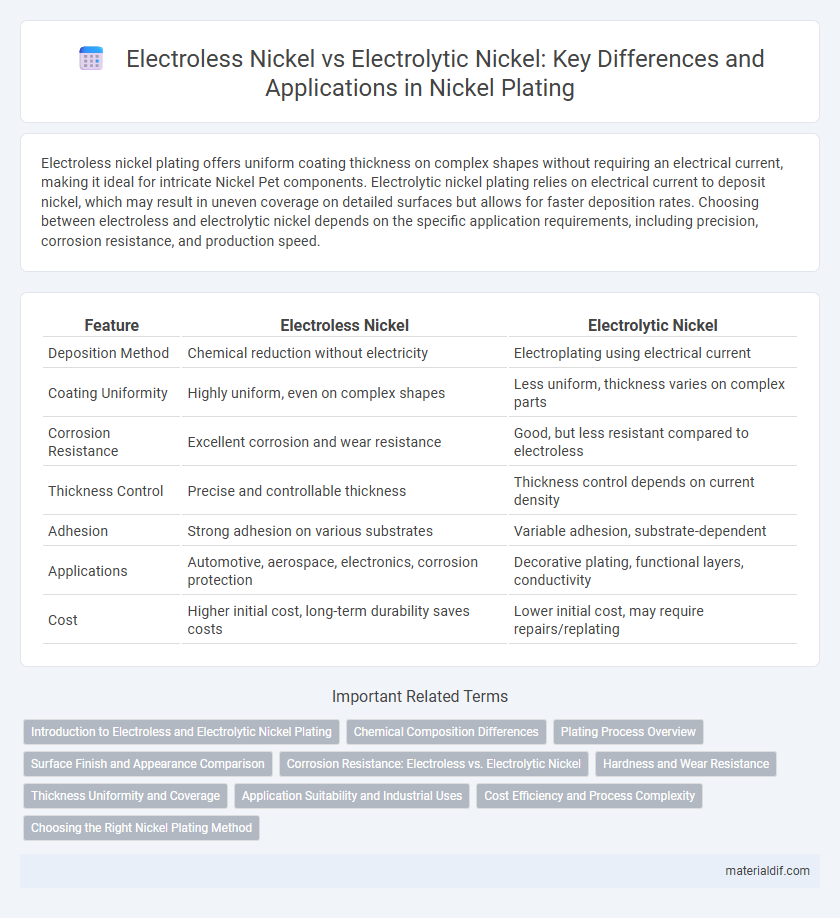

Electroless nickel plating offers uniform coating thickness on complex shapes without requiring an electrical current, making it ideal for intricate Nickel Pet components. Electrolytic nickel plating relies on electrical current to deposit nickel, which may result in uneven coverage on detailed surfaces but allows for faster deposition rates. Choosing between electroless and electrolytic nickel depends on the specific application requirements, including precision, corrosion resistance, and production speed.

Table of Comparison

| Feature | Electroless Nickel | Electrolytic Nickel |

|---|---|---|

| Deposition Method | Chemical reduction without electricity | Electroplating using electrical current |

| Coating Uniformity | Highly uniform, even on complex shapes | Less uniform, thickness varies on complex parts |

| Corrosion Resistance | Excellent corrosion and wear resistance | Good, but less resistant compared to electroless |

| Thickness Control | Precise and controllable thickness | Thickness control depends on current density |

| Adhesion | Strong adhesion on various substrates | Variable adhesion, substrate-dependent |

| Applications | Automotive, aerospace, electronics, corrosion protection | Decorative plating, functional layers, conductivity |

| Cost | Higher initial cost, long-term durability saves costs | Lower initial cost, may require repairs/replating |

Introduction to Electroless and Electrolytic Nickel Plating

Electroless nickel plating deposits a uniform nickel-phosphorus alloy layer through a chemical reduction process without the need for electrical current, providing excellent corrosion resistance and wear protection on complex geometries. Electrolytic nickel plating, also known as electroplating, relies on an electric current to deposit a pure nickel layer, offering precise thickness control and superior adhesion on conductive surfaces. Both methods enhance surface hardness and corrosion resistance but differ in deposition mechanism, coating uniformity, and application suitability.

Chemical Composition Differences

Electroless nickel coatings primarily consist of a uniform nickel-phosphorus or nickel-boron alloy deposited through a chemical reduction process, lacking the need for electrical current. Electrolytic nickel, formed via electroplating, generally contains purer nickel with minimal alloying elements, and its composition can be varied by adjusting bath chemistry and current density. The phosphorus content in electroless nickel affects hardness and corrosion resistance, whereas electrolytic nickel's purity better suits applications requiring ductility and electrical conductivity.

Plating Process Overview

Electroless nickel plating uses a chemical reduction process to deposit a uniform nickel-phosphorus or nickel-boron alloy coating without electrical current, ensuring even coverage on complex geometries. Electrolytic nickel plating relies on an electric current to reduce nickel ions from an electrolyte solution, providing a controlled and adjustable thickness but often requiring conductive substrates. The electroless process offers superior corrosion resistance and wear properties due to its consistent deposit, while electrolytic plating allows for precise layer control and faster deposition rates.

Surface Finish and Appearance Comparison

Electroless nickel plating provides a uniform, smooth surface finish with excellent corrosion resistance and consistent thickness, ideal for complex shapes and intricate designs. Electrolytic nickel plating tends to produce a brighter, more lustrous appearance with slightly varied thickness, suitable for decorative applications requiring high reflectivity. Both methods enhance surface hardness, but electroless nickel offers superior wear resistance due to its homogeneous deposition.

Corrosion Resistance: Electroless vs. Electrolytic Nickel

Electroless nickel coatings offer superior corrosion resistance due to their uniform thickness and phosphorus content, which creates a non-porous, chemically stable barrier against oxidation and chemical attack. Electrolytic nickel, applied through electroplating, often results in uneven layers and lower phosphorus levels, making it more susceptible to crevice corrosion and pitting in aggressive environments. The inherent chemical properties of electroless nickel make it ideal for complex geometries needing consistent protection in harsh industrial applications.

Hardness and Wear Resistance

Electroless nickel coatings provide uniform hardness typically ranging from 550 to 700 HV, enhancing wear resistance through their consistent composition and dense microstructure. Electrolytic nickel plating often results in lower hardness, around 200 to 400 HV, due to its columnar grain structure, which reduces wear resistance under abrasive conditions. The superior hardness and uniformity of electroless nickel make it the preferred choice for applications requiring high durability and corrosion resistance.

Thickness Uniformity and Coverage

Electroless nickel plating offers superior thickness uniformity and coverage due to its autocatalytic chemical deposition process, which deposits a consistent nickel-phosphorus layer regardless of part geometry. In contrast, electrolytic nickel plating relies on an electric current, resulting in uneven thickness, especially on complex shapes and recessed areas. This makes electroless nickel ideal for applications requiring precise, uniform coatings on intricate components.

Application Suitability and Industrial Uses

Electroless nickel plating offers uniform coatings ideal for complex-shaped components in aerospace, electronics, and automotive industries, providing excellent corrosion resistance and wear protection without the need for electrical current. Electrolytic nickel plating is better suited for applications requiring precise thickness control and is commonly used in decorative finishes, electrical contacts, and hardware manufacturing. The selection depends on the component geometry and performance requirements, with electroless nickel preferred for uniformity and electrolytic nickel favored for cost-effective large-scale production.

Cost Efficiency and Process Complexity

Electroless nickel plating offers enhanced uniformity and corrosion resistance with moderate cost efficiency, making it ideal for complex geometries and precision components despite higher chemical reagent expenses. Electrolytic nickel plating generally features lower initial costs and faster deposition rates but requires rigorous electrical setup and less uniform coverage, leading to potential increased post-processing costs. Process complexity in electroless nickel involves chemical bath maintenance and strict temperature control, whereas electrolytic nickel depends heavily on electrical current regulation and plating bath conductivity for optimal performance.

Choosing the Right Nickel Plating Method

Electroless nickel plating provides uniform thickness and excellent corrosion resistance without the need for electrical current, making it ideal for complex geometries and precision components. Electrolytic nickel plating offers faster deposition and typically lower costs but may result in uneven coatings on intricate parts. Choosing the right nickel plating method depends on factors such as part geometry, desired coating uniformity, corrosion resistance requirements, and budget constraints.

Electroless nickel vs electrolytic nickel Infographic

materialdif.com

materialdif.com