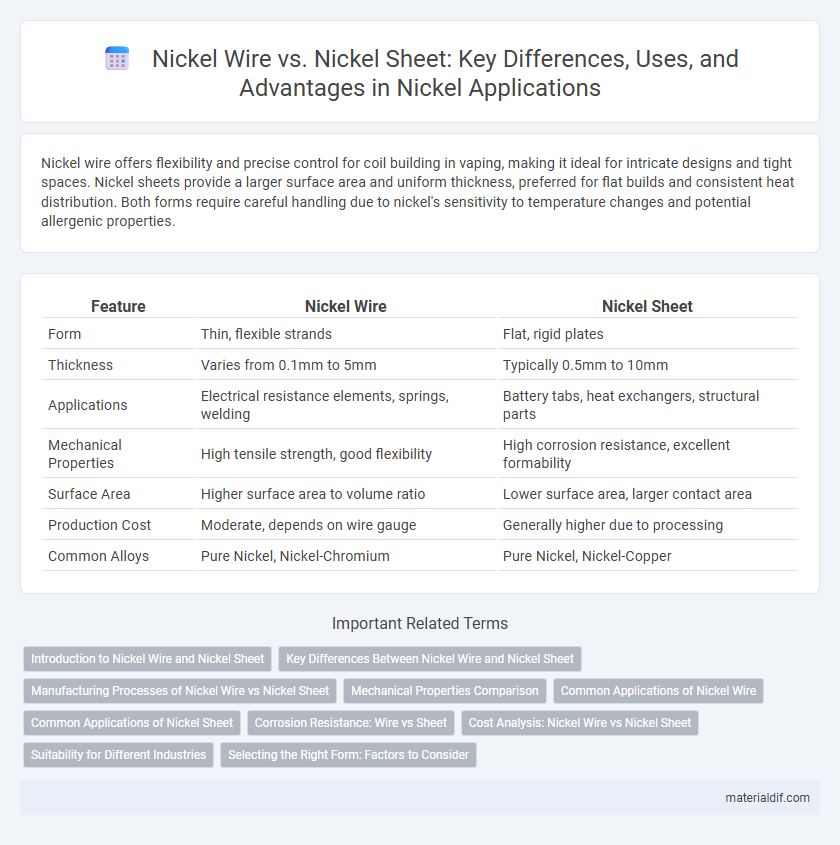

Nickel wire offers flexibility and precise control for coil building in vaping, making it ideal for intricate designs and tight spaces. Nickel sheets provide a larger surface area and uniform thickness, preferred for flat builds and consistent heat distribution. Both forms require careful handling due to nickel's sensitivity to temperature changes and potential allergenic properties.

Table of Comparison

| Feature | Nickel Wire | Nickel Sheet |

|---|---|---|

| Form | Thin, flexible strands | Flat, rigid plates |

| Thickness | Varies from 0.1mm to 5mm | Typically 0.5mm to 10mm |

| Applications | Electrical resistance elements, springs, welding | Battery tabs, heat exchangers, structural parts |

| Mechanical Properties | High tensile strength, good flexibility | High corrosion resistance, excellent formability |

| Surface Area | Higher surface area to volume ratio | Lower surface area, larger contact area |

| Production Cost | Moderate, depends on wire gauge | Generally higher due to processing |

| Common Alloys | Pure Nickel, Nickel-Chromium | Pure Nickel, Nickel-Copper |

Introduction to Nickel Wire and Nickel Sheet

Nickel wire offers excellent electrical conductivity and corrosion resistance, making it ideal for applications in electronics, heating elements, and resistance wires. Nickel sheet provides a durable, flat form suitable for fabrication, plating, and chemical processing industries requiring high strength and oxidation resistance. Both forms leverage nickel's exceptional thermal and mechanical properties to meet diverse industrial demands.

Key Differences Between Nickel Wire and Nickel Sheet

Nickel wire offers superior flexibility and is ideal for applications requiring intricate shapes or fine details, while nickel sheet provides a flat, rigid surface suitable for structural support and heat resistance. Wire forms excel in electrical conductivity and are commonly used in coil or filament production, whereas sheets are preferred for fabrication, plating, or corrosion-resistant barriers. Differences in thickness and surface area between wire and sheet types directly influence their mechanical properties and suitability for specific industrial uses.

Manufacturing Processes of Nickel Wire vs Nickel Sheet

Nickel wire is typically produced through a drawing process that involves pulling nickel rods through progressively smaller dies to achieve desired diameters, resulting in high tensile strength and flexibility. Nickel sheets are commonly manufactured using rolling processes, where molten nickel ingots are hot-rolled or cold-rolled into thin, flat sheets with uniform thickness and smooth surfaces. Both processes require precise temperature control and material handling to maintain the metal's corrosion resistance and mechanical properties essential for industrial applications.

Mechanical Properties Comparison

Nickel wire exhibits higher tensile strength and flexibility compared to nickel sheet, making it ideal for applications requiring durability under stress and intricate shaping. Nickel sheets offer superior hardness and rigidity, providing better resistance to wear and deformation in structural uses. The mechanical properties of nickel wire favor dynamic environments, while nickel sheets are suited for static, load-bearing applications.

Common Applications of Nickel Wire

Nickel wire is commonly used in electrical heating elements, resistance coils, and battery electrodes due to its excellent conductivity and corrosion resistance. It is preferred in applications requiring flexibility and precision, such as in aerospace wiring and medical devices. Nickel sheet, while also corrosion-resistant, is primarily utilized for structural components, plating, and corrosion-resistant barriers.

Common Applications of Nickel Sheet

Nickel sheets are commonly used in applications requiring corrosion resistance and high temperature strength, such as heat exchangers, chemical processing equipment, and battery casings. Their flat, durable form makes them ideal for fabricating reactors, electrical contacts, and aerospace components. Compared to nickel wire, which is favored for flexibility in wiring and coil springs, nickel sheets provide superior structural support and uniform surface coverage.

Corrosion Resistance: Wire vs Sheet

Nickel wire exhibits superior corrosion resistance due to its higher surface-to-volume ratio, allowing for quicker formation of a protective oxide layer in aggressive environments. In contrast, nickel sheets provide a more uniform and durable barrier against corrosion in static applications where exposure is consistent. The choice between nickel wire and sheet for corrosion resistance depends on application-specific factors such as surface area, environmental exposure, and mechanical stresses.

Cost Analysis: Nickel Wire vs Nickel Sheet

Nickel wire generally incurs higher production costs due to the extensive drawing and annealing processes required to achieve uniform thickness and tensile strength, whereas nickel sheets benefit from more straightforward rolling and slitting techniques, reducing manufacturing expenses. Market prices for nickel wire often reflect the added labor and precision involved, making it costlier per unit weight compared to nickel sheets. However, bulk purchasing of nickel sheets can further lower costs, enhancing their economic advantage for large-scale industrial applications.

Suitability for Different Industries

Nickel wire offers exceptional flexibility and precision, making it ideal for electronics, aerospace, and medical device industries where intricate components and reliable conductivity are crucial. Nickel sheets provide durable, corrosion-resistant surfaces favored in chemical processing, automotive, and construction sectors requiring robust structural materials and heat resistance. Both forms cater to industry-specific demands, with wire excelling in fine fabrication and sheets supporting heavy-duty applications.

Selecting the Right Form: Factors to Consider

Selecting the right form between nickel wire and nickel sheet depends on factors such as application requirements, mechanical strength, and ease of fabrication. Nickel wire offers superior flexibility and is ideal for intricate electrical and heating applications, while nickel sheet provides consistent thickness and strength suited for structural components and corrosion-resistant cladding. Consider surface area needs, thermal conductivity, and formability when choosing to optimize performance and cost-efficiency.

Nickel Wire vs Nickel Sheet Infographic

materialdif.com

materialdif.com