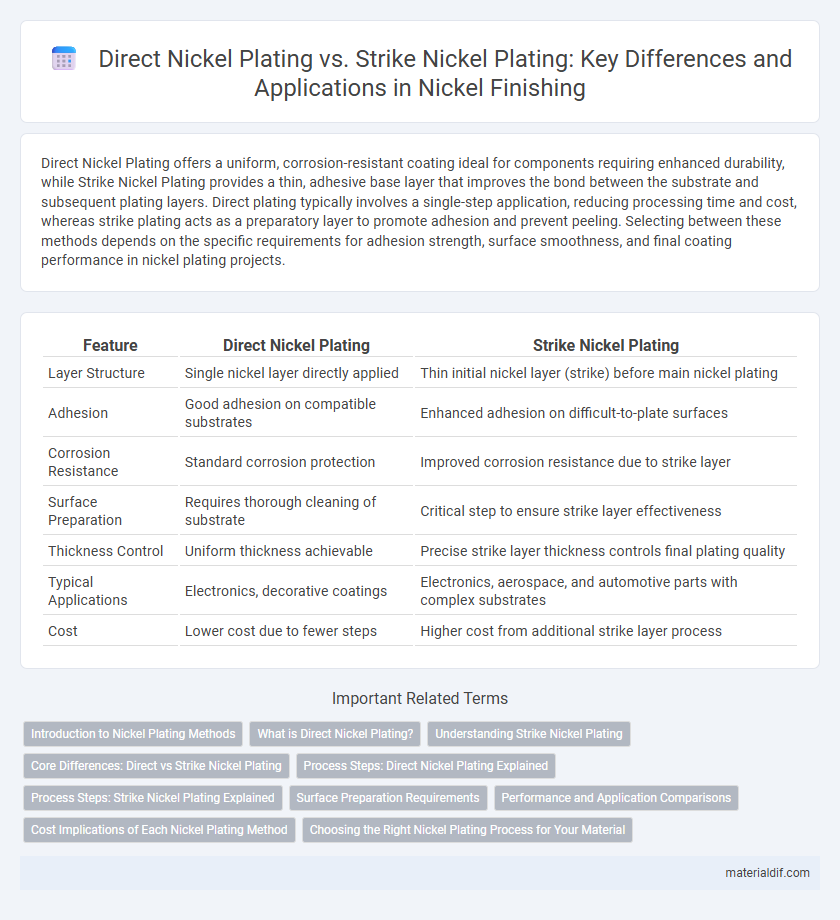

Direct Nickel Plating offers a uniform, corrosion-resistant coating ideal for components requiring enhanced durability, while Strike Nickel Plating provides a thin, adhesive base layer that improves the bond between the substrate and subsequent plating layers. Direct plating typically involves a single-step application, reducing processing time and cost, whereas strike plating acts as a preparatory layer to promote adhesion and prevent peeling. Selecting between these methods depends on the specific requirements for adhesion strength, surface smoothness, and final coating performance in nickel plating projects.

Table of Comparison

| Feature | Direct Nickel Plating | Strike Nickel Plating |

|---|---|---|

| Layer Structure | Single nickel layer directly applied | Thin initial nickel layer (strike) before main nickel plating |

| Adhesion | Good adhesion on compatible substrates | Enhanced adhesion on difficult-to-plate surfaces |

| Corrosion Resistance | Standard corrosion protection | Improved corrosion resistance due to strike layer |

| Surface Preparation | Requires thorough cleaning of substrate | Critical step to ensure strike layer effectiveness |

| Thickness Control | Uniform thickness achievable | Precise strike layer thickness controls final plating quality |

| Typical Applications | Electronics, decorative coatings | Electronics, aerospace, and automotive parts with complex substrates |

| Cost | Lower cost due to fewer steps | Higher cost from additional strike layer process |

Introduction to Nickel Plating Methods

Direct nickel plating deposits a uniform nickel layer directly onto the base metal, enhancing corrosion resistance and surface hardness without an intermediate layer. Strike nickel plating involves a thin, initial layer of nickel applied as a bonding agent to improve adhesion between the substrate and subsequent nickel deposits. Both methods are essential in electronics, automotive, and decorative industries for providing wear resistance and improved conductivity.

What is Direct Nickel Plating?

Direct nickel plating is a process where a single layer of nickel is deposited directly onto a metal substrate without using an intermediate strike layer. This method provides corrosion resistance and improved surface hardness, commonly applied to steel, copper, and aluminum parts. Direct nickel plating enhances wear resistance and electrical conductivity, making it suitable for various industrial applications.

Understanding Strike Nickel Plating

Strike nickel plating involves applying a thin, dense layer of nickel as a base coat to improve adhesion and corrosion resistance on challenging substrates, often preceding direct nickel plating. This initial strike layer ensures uniform coverage and enhances the durability of subsequent thicker nickel deposits. Understanding the precise control of thickness and deposition parameters in strike nickel plating is crucial for optimizing coating performance in industrial applications.

Core Differences: Direct vs Strike Nickel Plating

Direct nickel plating deposits a uniform nickel layer directly onto the substrate, providing excellent corrosion resistance and a smooth finish ideal for decorative and functional applications. Strike nickel plating involves applying a thin, initial nickel layer to improve adhesion between the substrate and subsequent thicker nickel layers, enhancing durability and reducing the risk of peeling. The core difference lies in the process purpose: direct plating serves as the main protective layer, while strike plating acts as a bonding intermediary in multi-layer plating systems.

Process Steps: Direct Nickel Plating Explained

Direct nickel plating involves a single plating process where a base metal surface is thoroughly cleaned, activated, and then immersed directly into a nickel electrolyte bath to deposit a uniform nickel layer. This method eliminates the need for a separate strike layer, reducing processing time and minimizing hydrogen embrittlement risks associated with multi-step procedures. By controlling parameters such as bath composition, temperature, and current density, direct nickel plating achieves consistent thickness and superior adhesion ideal for corrosion resistance and wear protection.

Process Steps: Strike Nickel Plating Explained

Strike nickel plating involves an initial thin nickel layer applied directly to a substrate through a highly concentrated nickel bath with low pH and high current density, ensuring enhanced adhesion and corrosion resistance. This preliminary step establishes a robust base layer before subsequent thicker nickel coatings are deposited in direct nickel plating, improving overall metal durability. The strike process is critical for surfaces prone to poor adhesion, such as aluminum or zinc die-cast parts, optimizing the plating's structural integrity and longevity.

Surface Preparation Requirements

Direct nickel plating requires rigorous surface preparation, including thorough cleaning, degreasing, and often acid activation, to ensure strong adhesion to the substrate. Strike nickel plating involves a thin initial layer applied under more stringent cleaning and activation processes, often including an additional etching step to create an optimal surface for the main nickel layer. Proper surface preparation in both methods is crucial to prevent peeling, corrosion, and ensure a uniform, durable nickel coating.

Performance and Application Comparisons

Direct nickel plating offers superior corrosion resistance and uniform coating thickness, making it ideal for decorative and functional applications in automotive and electronics industries. Strike nickel plating provides a thinner, high-adhesion layer that enhances subsequent plating processes, improving durability in complex assemblies such as connectors and precision instruments. Performance differences influence application choices, with direct nickel favored for external wear resistance and strike nickel used mainly as a preparatory step for multi-layer coatings.

Cost Implications of Each Nickel Plating Method

Direct nickel plating typically incurs lower overall costs by eliminating the initial strike layer, reducing material use and processing time. Strike nickel plating involves a thin, high-phosphorus layer that enhances adhesion but increases expenses due to additional chemical baths and longer cycle times. Choosing between direct and strike nickel plating impacts budgeting decisions based on part complexity, desired coating quality, and production volume.

Choosing the Right Nickel Plating Process for Your Material

Direct nickel plating offers superior adhesion and corrosion resistance by depositing nickel directly onto the substrate, making it ideal for materials with stable surfaces. Strike nickel plating acts as a thin, high-adhesion underlayer that enhances the bond between the substrate and subsequent thicker nickel layers, particularly useful for materials with poor surface energy or complex geometries. Selecting between direct and strike nickel plating depends on material composition, surface condition, and the desired coating performance in terms of durability and conductivity.

Direct Nickel Plating vs Strike Nickel Plating Infographic

materialdif.com

materialdif.com