Nickel Matte and Nickel Oxide are two common forms of nickel used in various industrial applications, each with distinct properties. Nickel Matte is a semi-refined product containing higher amounts of sulfur and other impurities, making it suitable for further refining processes. In contrast, Nickel Oxide is a refined compound that boasts higher purity and is primarily used in battery production and chemical manufacturing.

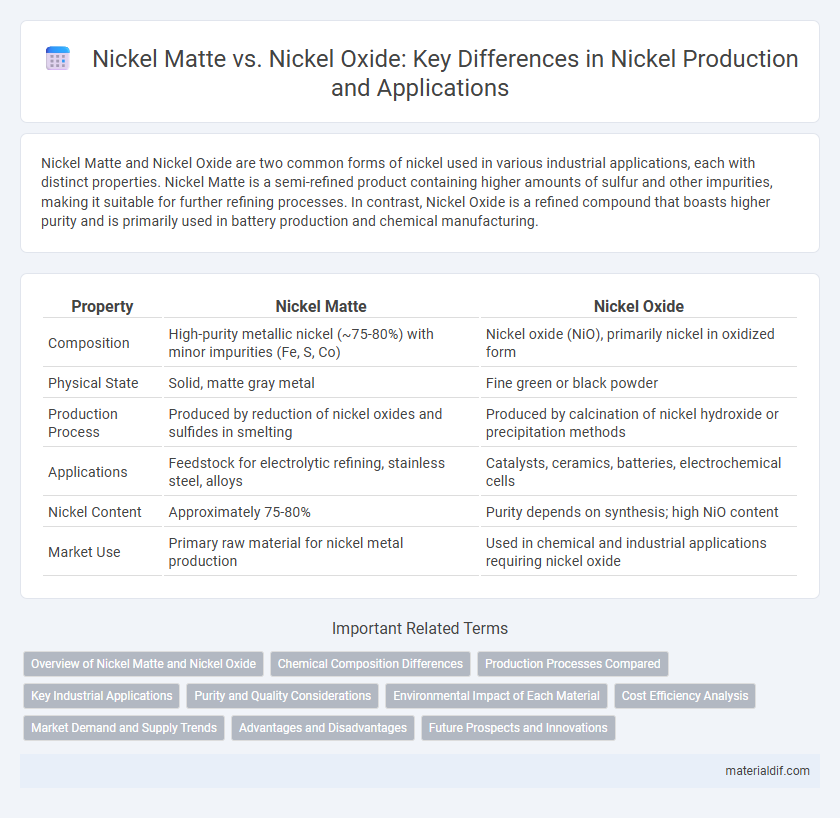

Table of Comparison

| Property | Nickel Matte | Nickel Oxide |

|---|---|---|

| Composition | High-purity metallic nickel (~75-80%) with minor impurities (Fe, S, Co) | Nickel oxide (NiO), primarily nickel in oxidized form |

| Physical State | Solid, matte gray metal | Fine green or black powder |

| Production Process | Produced by reduction of nickel oxides and sulfides in smelting | Produced by calcination of nickel hydroxide or precipitation methods |

| Applications | Feedstock for electrolytic refining, stainless steel, alloys | Catalysts, ceramics, batteries, electrochemical cells |

| Nickel Content | Approximately 75-80% | Purity depends on synthesis; high NiO content |

| Market Use | Primary raw material for nickel metal production | Used in chemical and industrial applications requiring nickel oxide |

Overview of Nickel Matte and Nickel Oxide

Nickel matte is an intermediate product in the nickel refining process that contains high levels of nickel, along with cobalt and iron impurities, typically produced through the smelting of laterite or sulfide ores. Nickel oxide, primarily used in battery cathodes and catalysts, is a refined chemical form derived from processing nickel matte or other nickel intermediates, characterized by its high purity and chemical stability. The distinction lies in nickel matte's role as a raw material concentrate, while nickel oxide serves as a critical industrial compound for advanced manufacturing applications.

Chemical Composition Differences

Nickel matte primarily consists of a high concentration of nickel metal (60-75%) combined with iron and sulfur impurities, while nickel oxide mainly contains nickel in its oxidized form (NiO) with oxygen bound to nickel atoms. The chemical composition of nickel matte is characterized by sulfide minerals such as pentlandite (Ni,Fe)9S8, whereas nickel oxide is an oxide compound with a crystalline structure containing nickel ions surrounded by oxygen ions. These compositional differences affect their physical and chemical properties, influencing their respective industrial applications and refining processes.

Production Processes Compared

Nickel matte is produced through the smelting of nickel sulfide ores, employing high-temperature pyrometallurgical processes that yield a sulfur-rich intermediate used for further refining. Nickel oxide is typically generated via hydrometallurgical methods, including roasting and leaching of laterite ores, resulting in a high-purity oxide suitable for battery cathode materials. The contrasting production techniques--pyrometallurgy for nickel matte and hydrometallurgy for nickel oxide--reflect the differing feedstocks and end-use applications in metal refining and battery manufacturing.

Key Industrial Applications

Nickel matte, containing higher concentrations of nickel and cobalt, is primarily used in stainless steel production and alloy manufacturing due to its favorable melting points and mechanical properties. Nickel oxide, with its higher purity and oxide form, plays a critical role in battery cathodes for electric vehicles and in ceramic glazes for corrosion resistance. Both materials serve as essential intermediates in refining processes but target distinct industrial sectors depending on their chemical composition and form.

Purity and Quality Considerations

Nickel matte contains lower nickel purity, typically around 70-80%, with impurities like sulfur and iron, affecting its quality and requiring further refining. Nickel oxide offers higher purity levels, often exceeding 99%, making it ideal for applications demanding superior material quality and corrosion resistance. Purity differences between nickel matte and nickel oxide significantly influence their suitability for industrial processes and final product performance.

Environmental Impact of Each Material

Nickel matte production generates significant sulfur dioxide emissions, contributing to acid rain and air pollution, while nickel oxide manufacturing typically results in lower SO2 emissions but may involve energy-intensive processes with associated carbon footprints. Waste from nickel matte refining often contains heavy metals and sulfur compounds posing soil and water contamination risks, whereas nickel oxide residues can include less hazardous byproducts with improved options for recycling and reuse. Evaluating lifecycle assessments reveals nickel oxide has a comparatively reduced environmental impact due to cleaner processing techniques and enhanced waste management practices.

Cost Efficiency Analysis

Nickel matte, an intermediate product in the nickel smelting process, generally offers higher cost efficiency due to its lower refining requirements compared to nickel oxide, which undergoes additional processing to achieve purity. The production of nickel oxide involves higher energy consumption and operational costs, making it less cost-effective at scale despite its use in specialized applications like battery cathodes. Evaluating the supply chain expenses, nickel matte's streamlined conversion pathway often results in reduced overall production costs, benefiting industries seeking economical nickel sources.

Market Demand and Supply Trends

Nickel matte, a primary intermediate in stainless steel production, experiences fluctuating market demand driven by the global stainless steel industry's growth, especially in Asia. Nickel oxide, used predominantly in battery cathodes for electric vehicles, shows increasing demand aligned with the expansion of the EV market and renewable energy storage. Supply trends reveal that nickel matte production is closely linked to sulfide ore mining, while nickel oxide supply depends more on laterite ore processing and refining capacities.

Advantages and Disadvantages

Nickel Matte offers a higher nickel content, typically around 75-80%, making it more efficient for refining processes, but it contains impurities like sulfur and iron that may require additional processing. Nickel Oxide has a higher purity level of around 99%, providing better performance in battery manufacturing and electroplating applications, though its production is more energy-intensive and costly. Choosing between Nickel Matte and Nickel Oxide depends on the specific industry demands, balancing cost efficiency and purity requirements.

Future Prospects and Innovations

Nickel Matte and Nickel Oxide both play crucial roles in the evolving battery and stainless steel industries, with Nickel Matte serving as a primary feedstock for refining high-purity nickel, essential for electric vehicle (EV) batteries. Innovations in hydrometallurgical and pyrometallurgical processes aim to enhance the extraction efficiency and purity of Nickel Matte, driving cost reductions and sustainability. Advances in Nickel Oxide applications focus on improving electrode performance in lithium-ion batteries, promising increased energy density and longer cycle life, aligning with future energy storage demands.

Nickel Matte vs Nickel Oxide Infographic

materialdif.com

materialdif.com