Nickel Sulfamate offers superior plating qualities with high ductility and low internal stress, making it ideal for precision metal finishing in nickel plating applications. Nickel Chloride, while easier to handle and less expensive, typically results in a less uniform deposit and higher internal stress, which may affect the durability of the plated component. Choosing between Nickel Sulfamate and Nickel Chloride depends on the specific performance requirements and cost considerations of the nickel plating process.

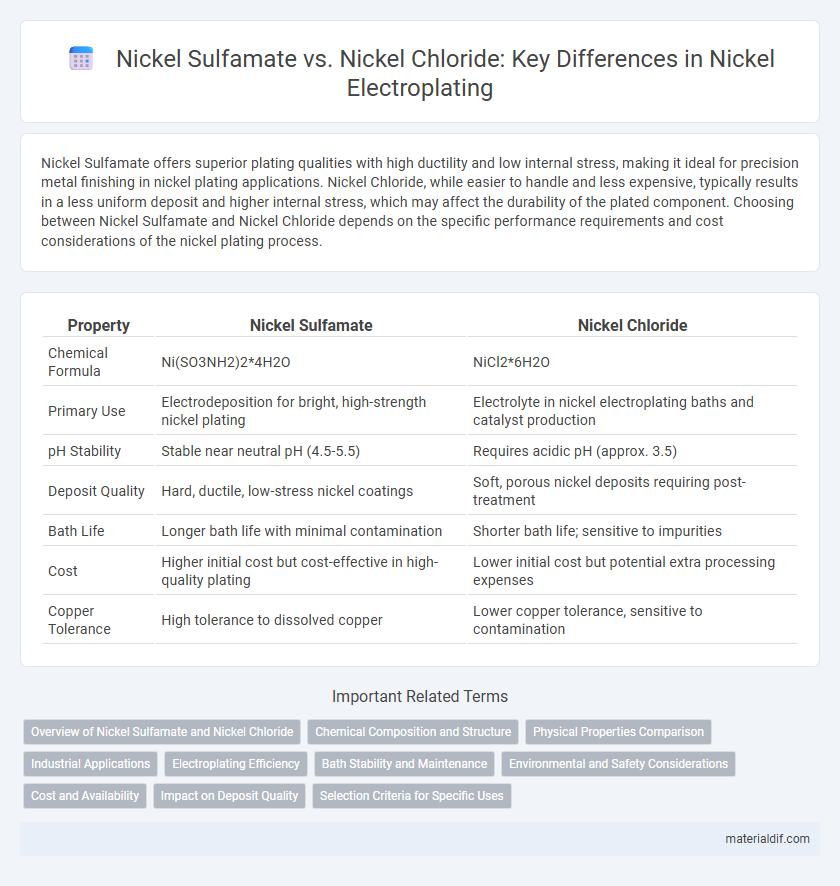

Table of Comparison

| Property | Nickel Sulfamate | Nickel Chloride |

|---|---|---|

| Chemical Formula | Ni(SO3NH2)2*4H2O | NiCl2*6H2O |

| Primary Use | Electrodeposition for bright, high-strength nickel plating | Electrolyte in nickel electroplating baths and catalyst production |

| pH Stability | Stable near neutral pH (4.5-5.5) | Requires acidic pH (approx. 3.5) |

| Deposit Quality | Hard, ductile, low-stress nickel coatings | Soft, porous nickel deposits requiring post-treatment |

| Bath Life | Longer bath life with minimal contamination | Shorter bath life; sensitive to impurities |

| Cost | Higher initial cost but cost-effective in high-quality plating | Lower initial cost but potential extra processing expenses |

| Copper Tolerance | High tolerance to dissolved copper | Lower copper tolerance, sensitive to contamination |

Overview of Nickel Sulfamate and Nickel Chloride

Nickel sulfamate is widely used in electroplating due to its excellent throwing power and ability to produce smooth, ductile nickel coatings with low internal stress, making it ideal for precision parts. Nickel chloride serves primarily to replenish nickel ions and improve anode corrosion in plating baths, helping maintain bath consistency and prolong electrode life. Both compounds are critical in nickel electroplating, with sulfamate favored for deposit quality and chloride for bath maintenance.

Chemical Composition and Structure

Nickel sulfamate consists of nickel ions coordinated with sulfamate anions, typically forming a stable complex used in electroplating due to its high nickel content and low internal stress deposits. In contrast, nickel chloride contains nickel ions bound to chloride ions, often resulting in a hexahydrated crystalline structure that influences its solubility and reactivity. The chemical composition and molecular geometry of nickel sulfamate provide superior conductivity and smoother deposit quality compared to the more corrosive and less stable nickel chloride solutions.

Physical Properties Comparison

Nickel sulfamate typically appears as a bright green crystalline solid, highly soluble in water, while nickel chloride presents as a yellow to green crystalline substance with moderate water solubility. The density of nickel sulfamate is approximately 2.6 g/cm3, contrasting with nickel chloride's density near 1.9 g/cm3, reflecting differences in molecular weight and crystal structure. Melting points also vary significantly; nickel sulfamate decomposes around 180degC, whereas nickel chloride melts at approximately 140degC, indicating distinct thermal stability profiles.

Industrial Applications

Nickel sulfamate is prized in industrial applications for its superior ability to produce smooth, ductile, and high-purity nickel deposits, making it ideal for precision plating in electronics and aerospace manufacturing. In contrast, nickel chloride is commonly used in electroplating processes requiring fast deposition rates but may result in rougher finishes, often found in automotive and decorative coatings. The choice between nickel sulfamate and nickel chloride depends on specific industrial requirements such as deposit quality, plating speed, and bath stability.

Electroplating Efficiency

Nickel sulfamate provides superior electroplating efficiency compared to nickel chloride due to its lower internal stress and higher deposition rate, resulting in smoother, more durable coatings. The sulfamate bath operates at a wider pH range and allows for higher current densities without causing hydrogen embrittlement or rough deposits, enhancing plating quality. Nickel chloride, while effective for initial activation, often requires careful control of chloride concentration to prevent corrosion and lower deposition rates during electroplating.

Bath Stability and Maintenance

Nickel sulfamate baths offer superior stability due to their resistance to decomposition and minimal hydrogen embrittlement compared to nickel chloride baths, which are prone to rapid degradation and complex maintenance requirements. The sulfamate electrolyte maintains consistent pH and nickel ion concentration, reducing the need for frequent replenishment and ensuring uniform deposit quality. In contrast, nickel chloride baths require careful monitoring and frequent chloride ion adjustments to prevent bath breakdown and maintain plating efficiency.

Environmental and Safety Considerations

Nickel sulfamate offers a safer alternative to nickel chloride due to its lower toxicity and reduced environmental impact during electroplating processes. Unlike nickel chloride, which contains harmful chlorine ions that can generate hazardous byproducts and require special waste treatment, nickel sulfamate solutions produce less hazardous waste and exhibit greater chemical stability. Selecting nickel sulfamate minimizes risks associated with corrosive fumes and waste disposal, aligning better with environmental regulations and workplace safety standards.

Cost and Availability

Nickel sulfamate typically costs more than nickel chloride due to its high purity and specialized manufacturing process, making it preferred for precise electroplating applications. Nickel chloride is more widely available and economical, driven by broader industrial use and simpler production methods. The choice between the two depends on balancing cost-effectiveness with the specific requirements of plating quality and substrate compatibility.

Impact on Deposit Quality

Nickel sulfamate produces smoother, denser deposits with superior brightness and ductility, making it ideal for high-quality electroplating applications. In contrast, nickel chloride often results in rougher deposits with lower ductility and brightness, which can compromise corrosion resistance. The choice of nickel source directly impacts the microstructure and overall performance of the plated layer.

Selection Criteria for Specific Uses

Nickel sulfamate is preferred for electrodeposition processes requiring high-purity, stress-free, and ductile nickel coatings due to its superior throwing power and ability to produce smooth deposits. Nickel chloride is commonly used as an additive to maintain bath stability and improve anode efficiency but can introduce higher stress and lower ductility in the final coating. Selection between nickel sulfamate and nickel chloride depends on application-specific factors such as required deposit thickness, mechanical properties, and bath maintenance needs.

Nickel Sulfamate vs Nickel Chloride Infographic

materialdif.com

materialdif.com