Nickel powder features fine, granular particles offering high surface area and excellent sintering properties, making it ideal for additive manufacturing and battery applications. Nickel flakes have a larger, plate-like structure that provides superior conductivity and improved corrosion resistance, commonly used in conductive coatings and anticorrosive paints. Choosing between nickel powder and flakes depends on the specific requirements of surface area, conductivity, and mechanical performance in industrial processes.

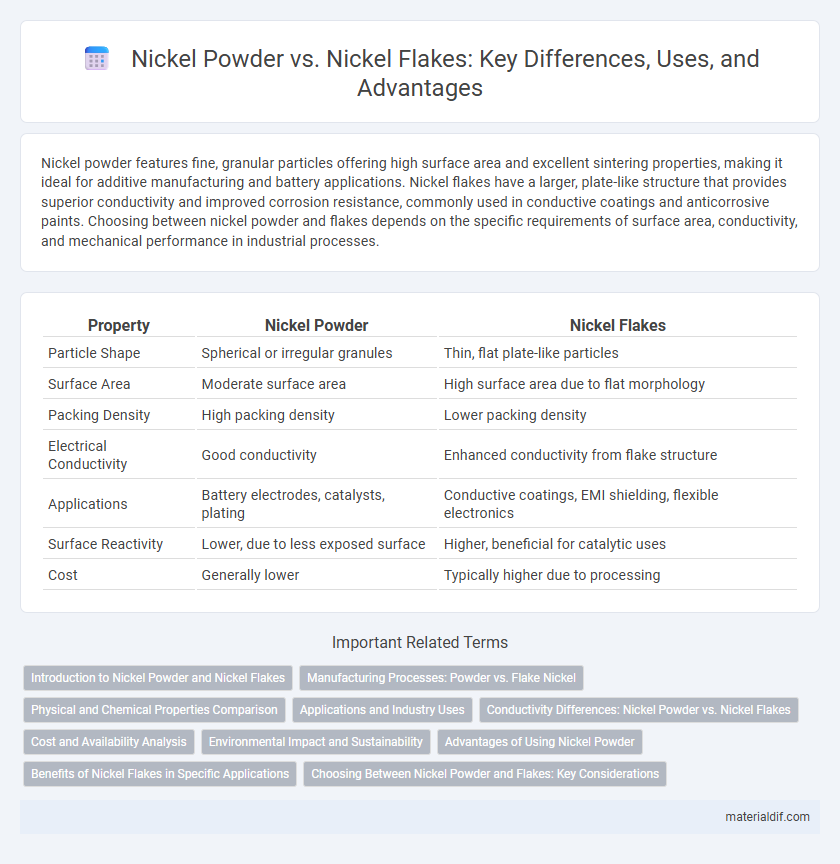

Table of Comparison

| Property | Nickel Powder | Nickel Flakes |

|---|---|---|

| Particle Shape | Spherical or irregular granules | Thin, flat plate-like particles |

| Surface Area | Moderate surface area | High surface area due to flat morphology |

| Packing Density | High packing density | Lower packing density |

| Electrical Conductivity | Good conductivity | Enhanced conductivity from flake structure |

| Applications | Battery electrodes, catalysts, plating | Conductive coatings, EMI shielding, flexible electronics |

| Surface Reactivity | Lower, due to less exposed surface | Higher, beneficial for catalytic uses |

| Cost | Generally lower | Typically higher due to processing |

Introduction to Nickel Powder and Nickel Flakes

Nickel powder consists of fine, spherical particles primarily used in powder metallurgy, electrical contacts, and battery electrodes due to its high surface area and conductivity. Nickel flakes have a flat, plate-like morphology that enhances their performance in coatings, catalysts, and conductive inks by providing superior coverage and improved electrical conductivity. Both forms offer distinct advantages in various industrial applications based on their particle shape and surface properties.

Manufacturing Processes: Powder vs. Flake Nickel

Nickel powder is produced through atomization or chemical reduction, resulting in fine, spherical particles ideal for uniform mixing and consistent surface area. Nickel flakes are manufactured by mechanically flattening powder particles or through electrolysis, yielding thin, plate-like shapes that enhance conductivity and packing density in coatings. The distinct manufacturing processes influence their physical properties, determining suitability for applications like battery electrodes, conductive films, or catalysts.

Physical and Chemical Properties Comparison

Nickel powder consists of fine, spherical particles with a high surface area, enhancing its reactivity and uniformity in chemical reactions. Nickel flakes, characterized by their flat, plate-like morphology, exhibit superior conductivity and improved packing density compared to powders. Both forms possess excellent corrosion resistance and magnetic properties, but the plate shape of flakes provides enhanced electrical contact in applications like batteries and conductive coatings.

Applications and Industry Uses

Nickel powder and nickel flakes are widely used in the chemical, battery, and electronics industries due to their high conductivity and corrosion resistance. Nickel powder is preferred in battery electrodes and catalysts for fuel cells because of its fine particle size and high surface area, enhancing electrochemical performance. Nickel flakes are typically utilized in conductive coatings, inks, and EMI shielding materials, where their flat shape provides superior coverage and electrical conductivity.

Conductivity Differences: Nickel Powder vs. Nickel Flakes

Nickel flakes exhibit higher electrical conductivity compared to nickel powder due to their larger surface area and improved particle contact, which facilitates electron flow. The flat, plate-like structure of nickel flakes minimizes voids within conductive composites, enhancing overall conductivity more effectively than spherical nickel powder particles. Consequently, nickel flakes are preferred in applications requiring superior conductive performance, such as conductive inks, coatings, and battery electrodes.

Cost and Availability Analysis

Nickel powder generally offers greater availability and lower cost compared to nickel flakes due to more established production processes and higher demand across industries like battery manufacturing and coatings. Nickel flakes, with their specialized morphology suited for applications requiring specific surface area and conductivity, tend to be pricier and less readily available. Market trends indicate that fluctuations in raw material prices and manufacturing complexity directly impact the cost disparity between nickel powder and flakes.

Environmental Impact and Sustainability

Nickel powder and nickel flakes differ significantly in their environmental impact and sustainability, with nickel powder generally requiring more energy-intensive production processes that contribute to higher carbon emissions. Nickel flakes tend to have a lower environmental footprint due to their easier recycling potential and reduced waste during manufacturing. Sustainable use of nickel in powder or flake form depends on advancements in recycling technologies and the implementation of circular economy principles to minimize resource depletion.

Advantages of Using Nickel Powder

Nickel powder offers superior surface area and uniformity compared to nickel flakes, enhancing its reactivity and suitability for catalytic and battery applications. The fine morphology of nickel powder enables improved sintering and better electrical conductivity in additive manufacturing and electrode production. Its consistent particle size distribution ensures more reliable performance in chemical coatings and conductive pastes.

Benefits of Nickel Flakes in Specific Applications

Nickel flakes offer superior surface area and enhanced conductivity compared to nickel powder, making them ideal for use in electrical contacts and coatings. Their flat, thin structure provides better coverage and improved bonding in conductive adhesives and plating processes. These properties result in increased efficiency and durability in applications such as printed electronics and corrosion-resistant coatings.

Choosing Between Nickel Powder and Flakes: Key Considerations

Nickel powder offers a higher surface area and finer particle size ideal for catalytic and battery applications, while nickel flakes provide superior electrical conductivity and are preferred in conductive coatings and adhesives. The choice depends on specific application requirements such as particle morphology, chemical reactivity, and desired mechanical properties. Cost efficiency, ease of handling, and dispersion characteristics also play crucial roles in selecting between nickel powder and flakes.

Nickel powder vs nickel flakes Infographic

materialdif.com

materialdif.com