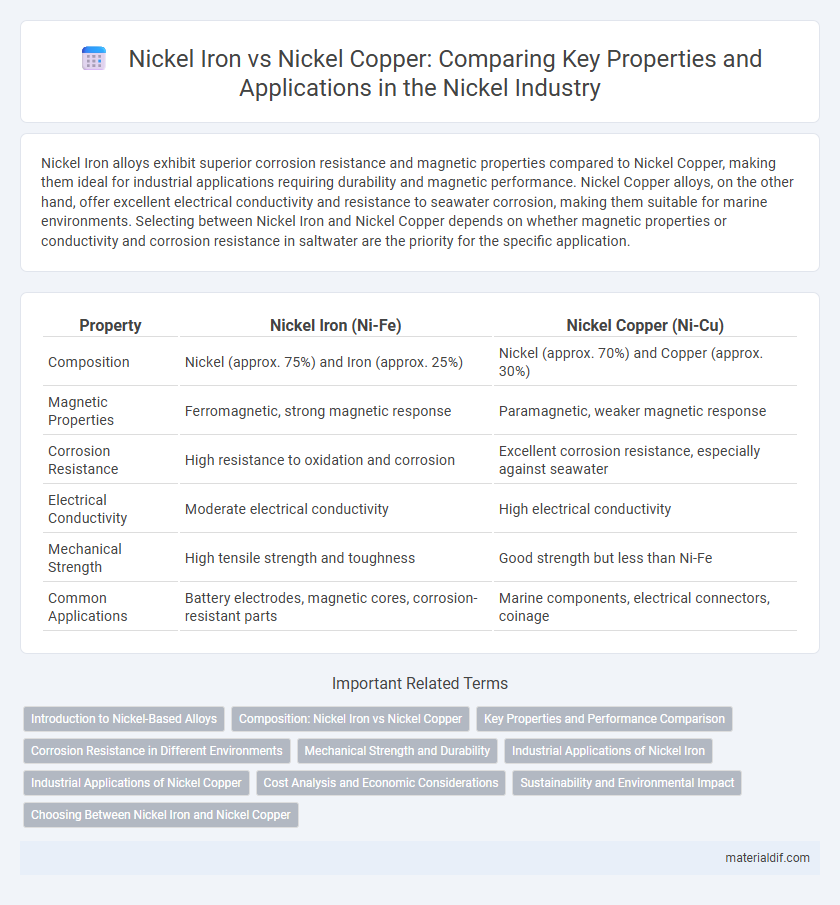

Nickel Iron alloys exhibit superior corrosion resistance and magnetic properties compared to Nickel Copper, making them ideal for industrial applications requiring durability and magnetic performance. Nickel Copper alloys, on the other hand, offer excellent electrical conductivity and resistance to seawater corrosion, making them suitable for marine environments. Selecting between Nickel Iron and Nickel Copper depends on whether magnetic properties or conductivity and corrosion resistance in saltwater are the priority for the specific application.

Table of Comparison

| Property | Nickel Iron (Ni-Fe) | Nickel Copper (Ni-Cu) |

|---|---|---|

| Composition | Nickel (approx. 75%) and Iron (approx. 25%) | Nickel (approx. 70%) and Copper (approx. 30%) |

| Magnetic Properties | Ferromagnetic, strong magnetic response | Paramagnetic, weaker magnetic response |

| Corrosion Resistance | High resistance to oxidation and corrosion | Excellent corrosion resistance, especially against seawater |

| Electrical Conductivity | Moderate electrical conductivity | High electrical conductivity |

| Mechanical Strength | High tensile strength and toughness | Good strength but less than Ni-Fe |

| Common Applications | Battery electrodes, magnetic cores, corrosion-resistant parts | Marine components, electrical connectors, coinage |

Introduction to Nickel-Based Alloys

Nickel-based alloys, primarily Nickel-Iron and Nickel-Copper, exhibit distinct properties suited for various industrial applications due to their unique elemental compositions. Nickel-Iron alloys, such as Invar, are renowned for their low thermal expansion and magnetic properties, making them ideal for precision instruments and aerospace components. In contrast, Nickel-Copper alloys offer superior corrosion resistance and excellent strength in marine environments, commonly used in seawater handling and chemical processing industries.

Composition: Nickel Iron vs Nickel Copper

Nickel Iron alloys primarily consist of approximately 70-80% nickel with the remainder being iron, providing high magnetic permeability and corrosion resistance. In contrast, Nickel Copper alloys, such as Monel, contain around 60-70% nickel combined with 20-30% copper, enhancing resistance to seawater corrosion and stress cracking. The distinct compositions of Nickel Iron and Nickel Copper dictate their specific applications in electronics, marine environments, and industrial processes.

Key Properties and Performance Comparison

Nickel Iron alloys exhibit superior magnetic permeability and corrosion resistance, making them ideal for electrical transformers and magnetic shielding applications. In contrast, Nickel Copper alloys offer enhanced thermal conductivity and excellent resistance to seawater corrosion, which is crucial for marine and chemical processing industries. Both alloys maintain strong mechanical stability, but Nickel Iron is favored for magnetic performance, whereas Nickel Copper excels in thermal and chemical durability.

Corrosion Resistance in Different Environments

Nickel Iron alloys exhibit superior corrosion resistance in acidic and alkaline environments due to their stable oxide layer formation, making them ideal for chemical processing applications. Nickel Copper alloys demonstrate excellent resistance to seawater and chlorides, with enhanced performance in marine environments and desalination plants. The choice between Nickel Iron and Nickel Copper depends on the specific corrosive agents and operational conditions present in the intended application.

Mechanical Strength and Durability

Nickel-Iron alloys exhibit superior mechanical strength and durability compared to Nickel-Copper alloys, making them ideal for heavy-duty applications and environments with high stress or thermal cycling. The higher iron content in Nickel-Iron enhances tensile strength and resistance to wear, whereas Nickel-Copper alloys offer better corrosion resistance but lower mechanical robustness. Industrial uses demanding long-term structural integrity often prefer Nickel-Iron for its enhanced hardness and fatigue resistance.

Industrial Applications of Nickel Iron

Nickel iron alloys exhibit exceptional magnetic properties and corrosion resistance, making them ideal for industrial applications such as transformers, magnetic shielding, and precision instruments. Their high electrical conductivity and thermal stability outperform nickel copper in environments demanding durability and strong magnetic performance. Industries including electronics, aerospace, and energy rely on nickel iron for components requiring reliable long-term operation under harsh conditions.

Industrial Applications of Nickel Copper

Nickel-copper alloys are highly valued in industrial applications for their exceptional corrosion resistance and thermal stability, making them ideal for marine engineering, chemical processing, and aerospace components. Unlike nickel-iron, which is primarily used in magnetic and electrical applications, nickel-copper alloys excel in environments exposed to seawater and acidic conditions thanks to their anti-fouling properties and strength. Industries leverage nickel-copper's ability to withstand harsh environments while maintaining conductivity and mechanical durability in heat exchangers, valves, and desalination plants.

Cost Analysis and Economic Considerations

Nickel iron alloys generally incur higher production costs compared to nickel copper due to the energy-intensive refining processes and limited raw material availability. Economic considerations favor nickel copper in applications where cost-efficiency is critical, given its lower material and manufacturing expenses. Price volatility in global nickel markets significantly impacts both alloys but tends to affect nickel iron more due to its reliance on purer nickel grades.

Sustainability and Environmental Impact

Nickel-iron alloys demonstrate superior sustainability due to their higher recyclability and lower energy consumption during production compared to nickel-copper alloys. Nickel-copper combinations often involve mining processes that generate more toxic waste, contributing to greater environmental degradation. The reduced ecological footprint of nickel-iron makes it a preferred choice in applications prioritizing environmental impact and circular economy principles.

Choosing Between Nickel Iron and Nickel Copper

Choosing between nickel iron and nickel copper alloys hinges on application-specific factors such as corrosion resistance, magnetic properties, and mechanical strength. Nickel iron alloys provide superior magnetic permeability and excellent resistance to oxidation, making them ideal for electrical and magnetic applications. Nickel copper alloys offer greater resistance to seawater corrosion and enhanced ductility, which suits marine and chemical processing environments better.

Nickel Iron vs Nickel Copper Infographic

materialdif.com

materialdif.com